9.1.2 MTTR

Note

The operating conditions can vary greatly. For that reason, the following table only states

general intervals for inspections and service during fault-free operation.

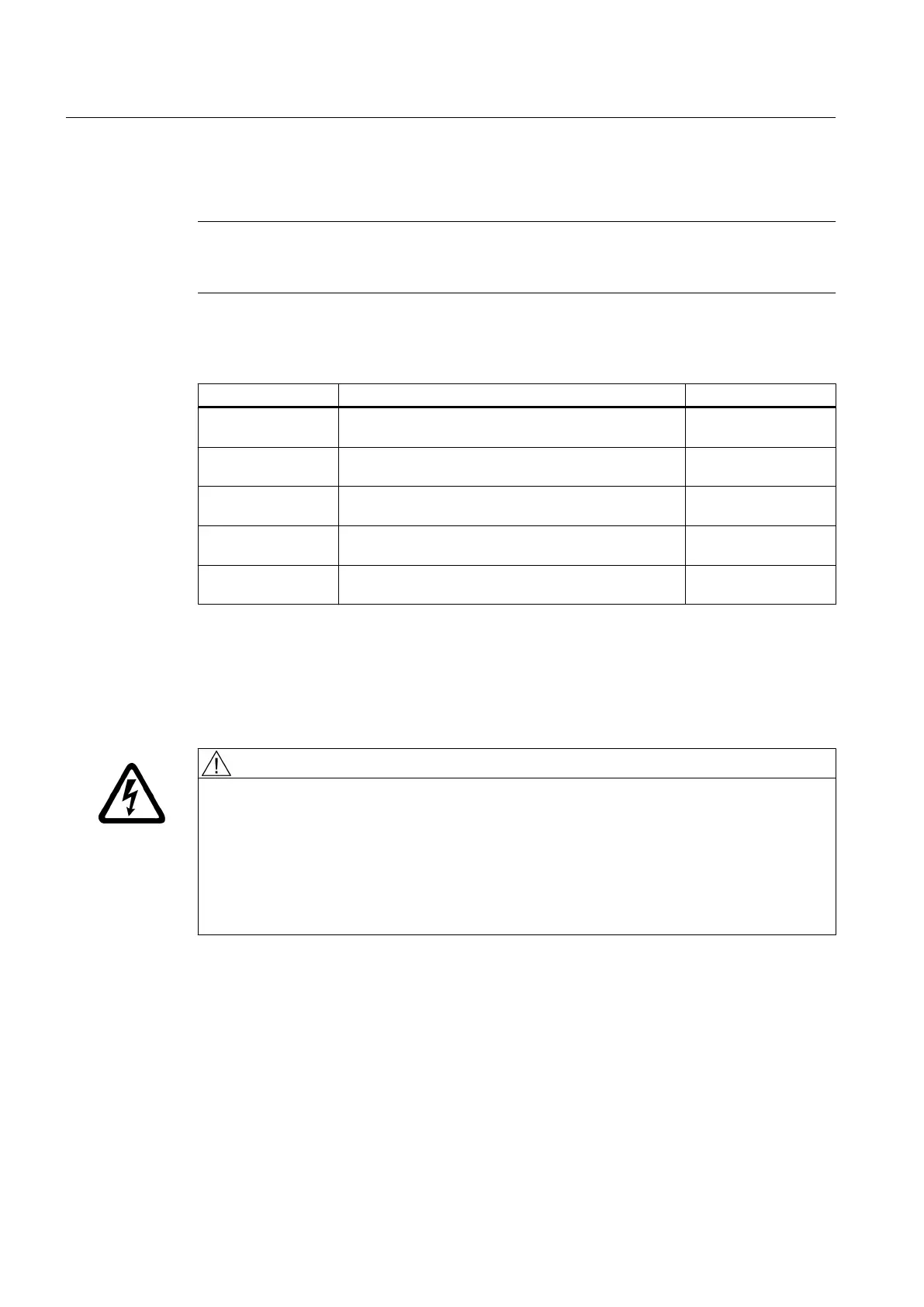

Table 9-1 MTTR in fault-free operation

Measure Interval Time limit

Initial inspection After 500 operating hours After a half year at the

latest

Regreasing After 1000 to 16 000 operating hours (depending on

bearings and operating mode)

After three years at

the latest

Cleaning Dependent on local degree of pollution or when brush‐

es are replaced

Follow-up inspection 2,000 operating hours after the previous inspection After a half year at the

latest

General inspection Approximately every 16 000 operating hours After two years at the

latest

9.1.3 Main inspection

The main inspection of the machine should be carried out after approximately 16000 operating

hours, but no later than after two years of operation.

DANGER

Rotating or live parts

Rotating or live parts are dangerous. Death, serious injury, or material damage can result if

the required covers are removed.

If no inspection windows are fitted and, as a result, the appropriate covers need to be removed

to allow inspection of the commutating performance, these covers may only be dismounted

by specially qualified personnel. This ensures that there is no contact with live or moving

parts. Wear safety goggles when working.

Checking the motor when in operation

● The relevant technical data are observed: power consumption, temperature of windings,

bearings, coolants, etc.

● There should be no oil, grease, or water leakages.

● The smooth running characteristics and motor running noise have not deteriorated.

● No impermissible brush sparking occurs in operation.

Maintenance

9.1 Inspection and maintenance

SIMOTICS DC 1GG6

86 Operating Instructions 02/2016

Loading...

Loading...