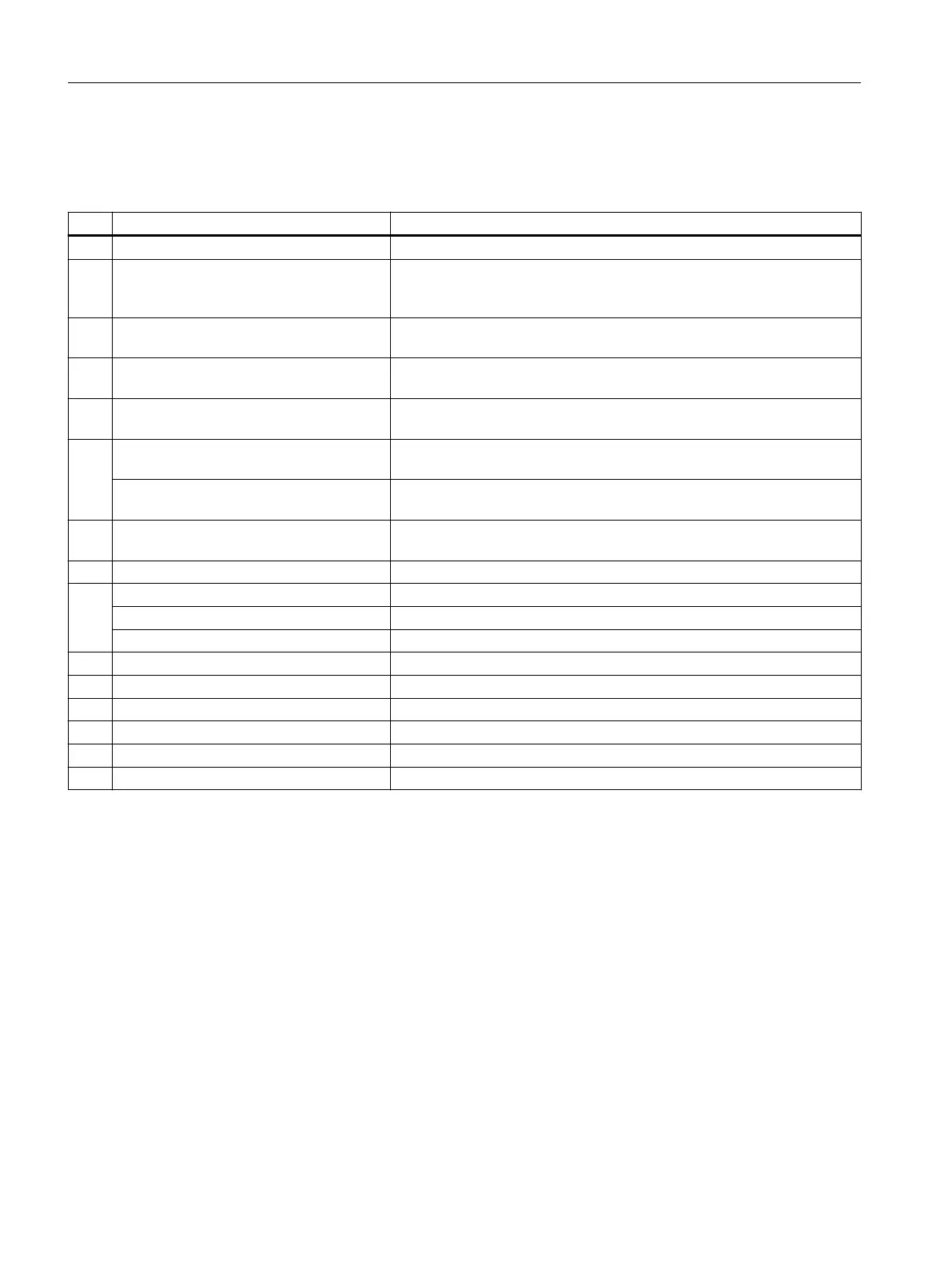

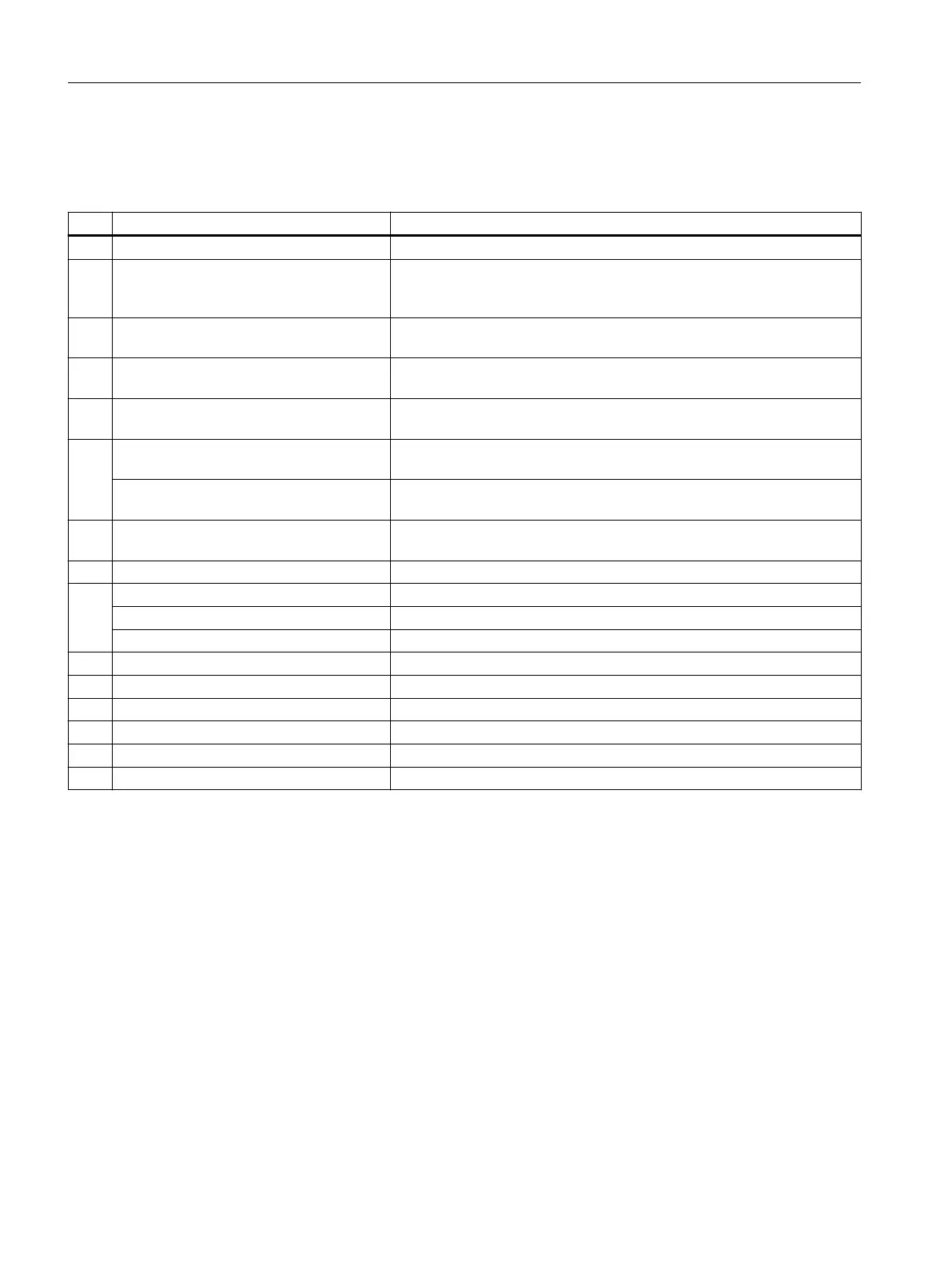

Table 9-2 "Fault causes and remedial measures" key table

No. Fault cause Remedial measures

A Overload Reduce load

B Interruption of a phase in the supply cable /

motor winding

Check the frequency converter and supply cables, measure the winding

resistances and insulation resistances, repair after consultation with man‐

ufacturer

C Interrupted phase in the feeder cable after

switching on

Check the frequency converter, supply cables and the winding resistances

D Converter output voltage too high, fre‐

quency too low

Check the settings on the frequency converter, perform automatic motor

identication

F Winding short-circuit or phase short-circuit

in stator winding

Measure the winding resistances and insulation resistances, repair after

consultation with the manufacturer, if required, replace the motor

I Heat dissipation impeded by dirt Clean the surface of the drives and ensure that the cooling air can ow in

and out unimpeded

Cooling air inlet/outlet is blocked by for‐

eign bodies

Remove the reason for the blocking and ensure that the cooling air can

ow in and out unimpeded

J Insucient shielding for motor and/or en‐

coder cable

Check the shielding and grounding

K Excessive drive controller gain Adjust the controller

L Rotating parts are grinding Determine cause and adjust parts

Foreign bodies inside the motor Replace the motor

Bearing damage Replace the motor

M Rotor not balanced Replace the motor

N Rotor out of true, shaft bent Consult the manufacturer

O Poor alignment Align motor set, check coupling

P Coupled machine not balanced Re-balance coupled machine

Q Shocks from coupled machine Check coupled machine

R Fault originating from the gearbox Adjust/repair gearbox

If the fault still cannot be resolved after taking the measures stated above, please contact the

manufacturer or the Siemens Service Center.

Faults and their rectication

SIMOTICS S-1FK2 synchronous motors for SINAMICS S120

92 Operating Instructions, 02/2022, A5E46089564B AD

Loading...

Loading...