SINAMICS G130

Engineering Information

SINAMICS Engineering Manual – November 2015

Ó Siemens AG

280/528

Overload and overtemperature protection

SINAMICS G130 Chassis are equipped with effective overload and overtemperature protection mechanisms which

protect them against thermal overloading.

Sensors at various locations in the converter (inlet air, control electronics, rectifier heatsink, inverter heatsink)

measure the relevant temperatures and feed them into the so-called "Thermal model". This continuously calculates

the temperature at critical positions on power components. In this way the converter is effectively protected against

thermal overloads, whether they are caused by excessive current or high ambient temperatures. The so-called "I

2

t"

monitoring circuit checks the level of utilization of the motor-side inverter. If the level of inverter utilization or the

temperature at any point in the converter exceeds the upper tolerance limit, the converter responds by initiating an

overload reaction parameterized in the firmware. It is possible to select whether the converter should react to

overload by reducing the output frequency and output current or the pulse frequency. Immediate shutdown can also

be parameterized.

Maximum output frequency

With SINAMICS G130 Chassis units, the maximum output frequency is limited to 100 Hz or 160 Hz due to the

factory-set pulse frequency of f

Pulse

= 1.25 kHz (current controller clock cycle = 400 μs) or f

Pulse

= 2.00 kHz (current

controller clock cycle = 250 μs) The pulse frequency must be increased if higher output frequencies are to be

achieved. Since the switching losses in the motor-side IGBT inverter increase when the pulse frequency is raised, the

output current must be reduced accordingly.

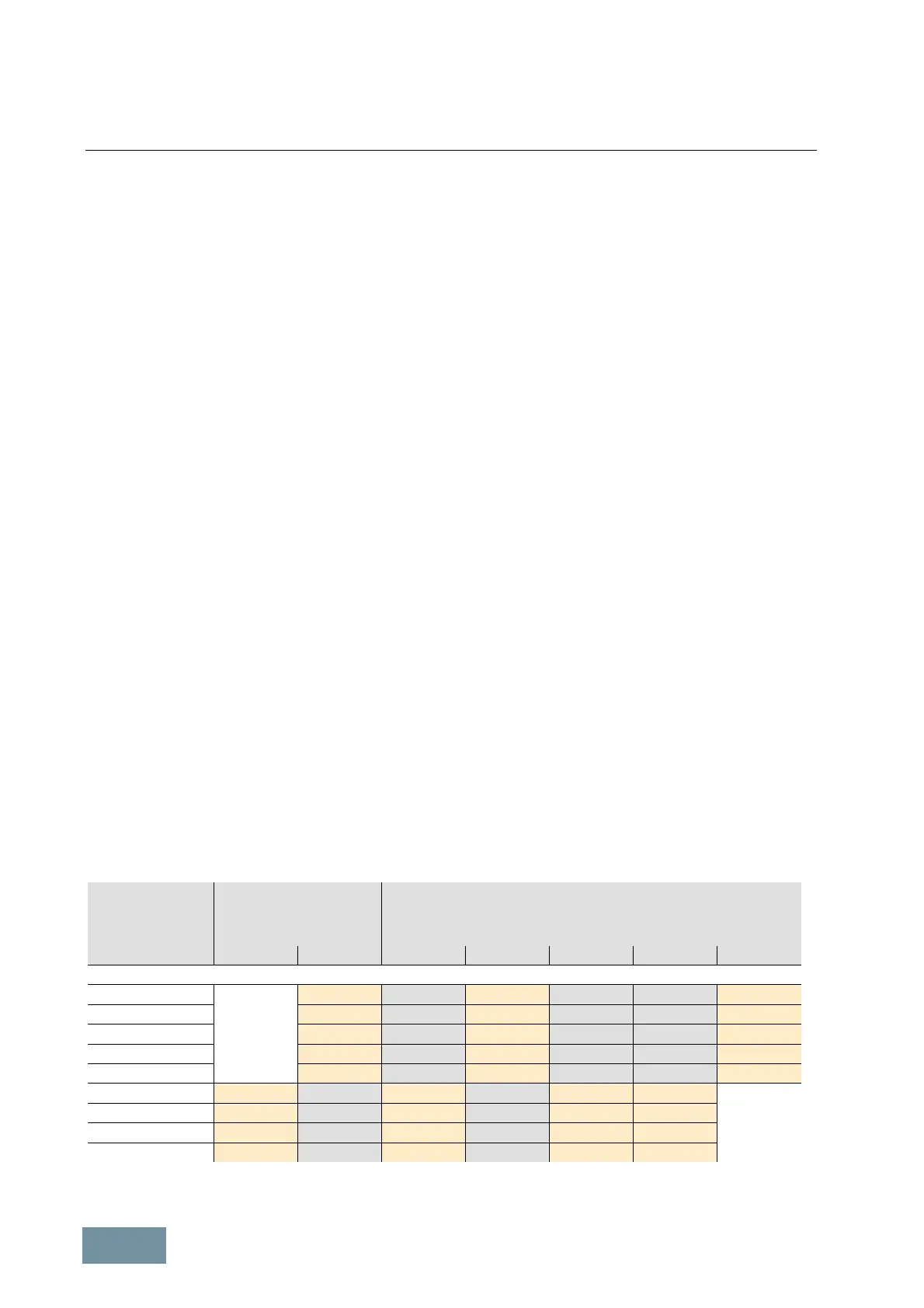

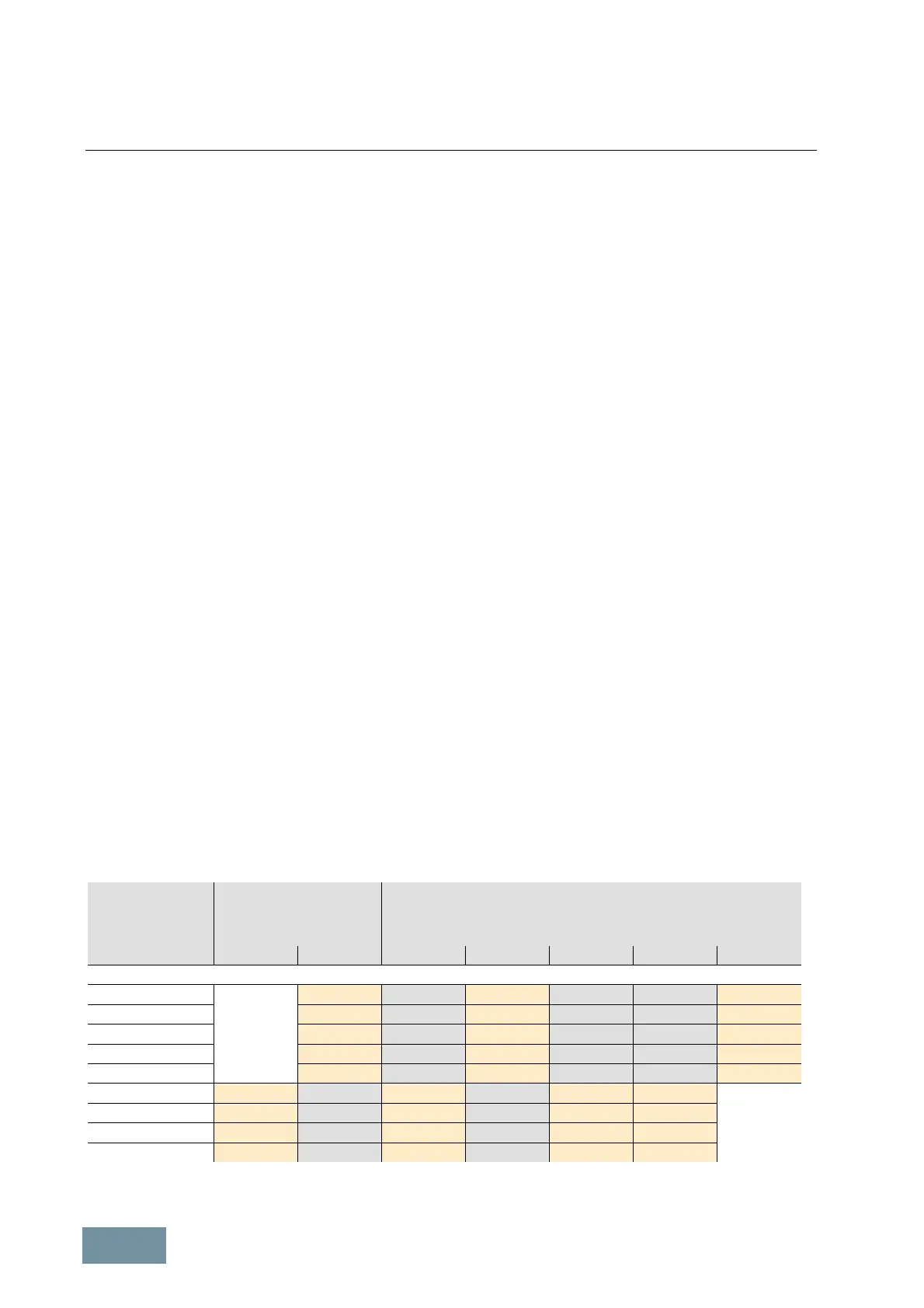

Permissible output current and maximum output frequency as a function of pulse frequency

The table below states the rated output currents of SINAMICS G130 converters with the factory-set pulse frequency,

as well as the current derating factors (permissible output currents referred to the rated output current) at higher

pulse frequencies.

The pulse frequencies for the values in the orange boxes can be selected simply by changing a parameter (even

during operation), i.e. they do not necessitate a change to the factory-set current controller clock cycle. The pulse

frequencies for the values in the grey boxes require a change in the factory-set current controller clock cycle and can

therefore be selected only at the commissioning stage. The assignment between current controller clock cycles and

possible pulse frequencies can be found in the List Manual (Parameter List).

Under certain boundary conditions (line voltage at low end of permissible wide-voltage range, low ambient

temperature, restricted speed range), it is possible to partially or completely avoid current derating at pulse

frequencies which are twice as high as the factory setting. Further details can be found in section "Operation of

converters at increased pulse frequency".

Output power

at

400V / 500V / 690 V

Rated output current

or

current derating factor

with pulse frequency of

Current derating factor

with pulse frequency of

1.25 kHz 2.0 kHz 2.5 kHz 4.0 kHz 5.0 kHz 7.5 kHz 8.0 kHz

380 V – 480 V 3AC

110 kW 210 A 95 % 82 % 74 % 54 % 50 %

132 kW 260 A 95 % 83 % 74 % 54 % 50 %

160 kW 310 A 97 % 88 % 78 % 54 % 50 %

200 kW 380 A 96 % 87 % 77 % 54 % 50 %

250 kW 490 A 94 % 78 % 71 % 53 % 50 %

315 kW 605 A 83 % 72 % 64 % 60 % 40 %

400 kW 745 A 83 % 72 % 64 % 60 % 40 %

450 kW 840 A 87 % 79 % 64 % 55 % 40 %

560 kW 985 A 92 % 87 % 70 % 60 % 50 %

SINAMICS G130: Permissible output current (current derating factor) as a function of pulse frequency

Loading...

Loading...