Parameter Manual

Operating Instructions, 08/2013, 6FC5397-8EP40-0BA0

103

Machine data

2.3 Channel-specific machine data

Description: Definition of the initial setting of the control after ramp-up and at reset/

end-of-part-program with regard to the G codes (in particular the active

plane and the settable work offset), tool length offset and transformation by

setting the following bits:

Bit 0: Reset mode

Bit 1: Suppress aux. funct. output on tool selection

Bit 2: Select reset response after power-on (e.g. tool offset)

Bit 3: Select reset response after end of test mode with regard to active

tool offsets.

Bit 4: Reserved

Bit 5: Reserved

Bit 6: Reset response "Active tool length offset"

Bit 7: Reset response "Active kinematic transformation"

Bit 8: Reset response "Coupled-motion axes"

Bit 9: Reset response "Tangential correction"

Bit 10: Reset response "Synchronous spindle"

Bit 11: Reset response "Revolutional feedrate"

Bit 12: Reset response "Geo axis replacement"

Bit 13: Reset response "Master value coupling"

Bit 14: Reset response "Basis frame"

Bit 15: Reset response "Electronic gearbox"

Bit 16: Reset response "Master spindle"

Bit 17: Reset response "Master toolholder"

Bit 18: Reset response "Reference axis for G96/G961/G962"

Bit 19: Reserved "Adjustable software limit switch ineffective"

Bits 4 to 11, 16 and 17 are only evaluated for bit 0 = 1.

Meaning of the individual bits:

Bit 0 (LSB) = 0: corresponds to the behavior of SW release 1, is only recom-

mended for test mode

Initial setting after ramp-up:

- G codes according to MD20150 $MC_GCODE_RESET_VALUES

- Tool length offset not active

- Transformation not active

- No coupled-motion axis groupings active

- No tangential correction active

- No axial revolutional feedrate active

- Path revolutional feedrate with master spindle (default))

Initial setting after reset or end-of-part-program:

The current settings are retained.

When next part program is started, the following initial setting is effec-

tive:

- G codes according to MD20150 $MC_GCODE_RESET_VALUES

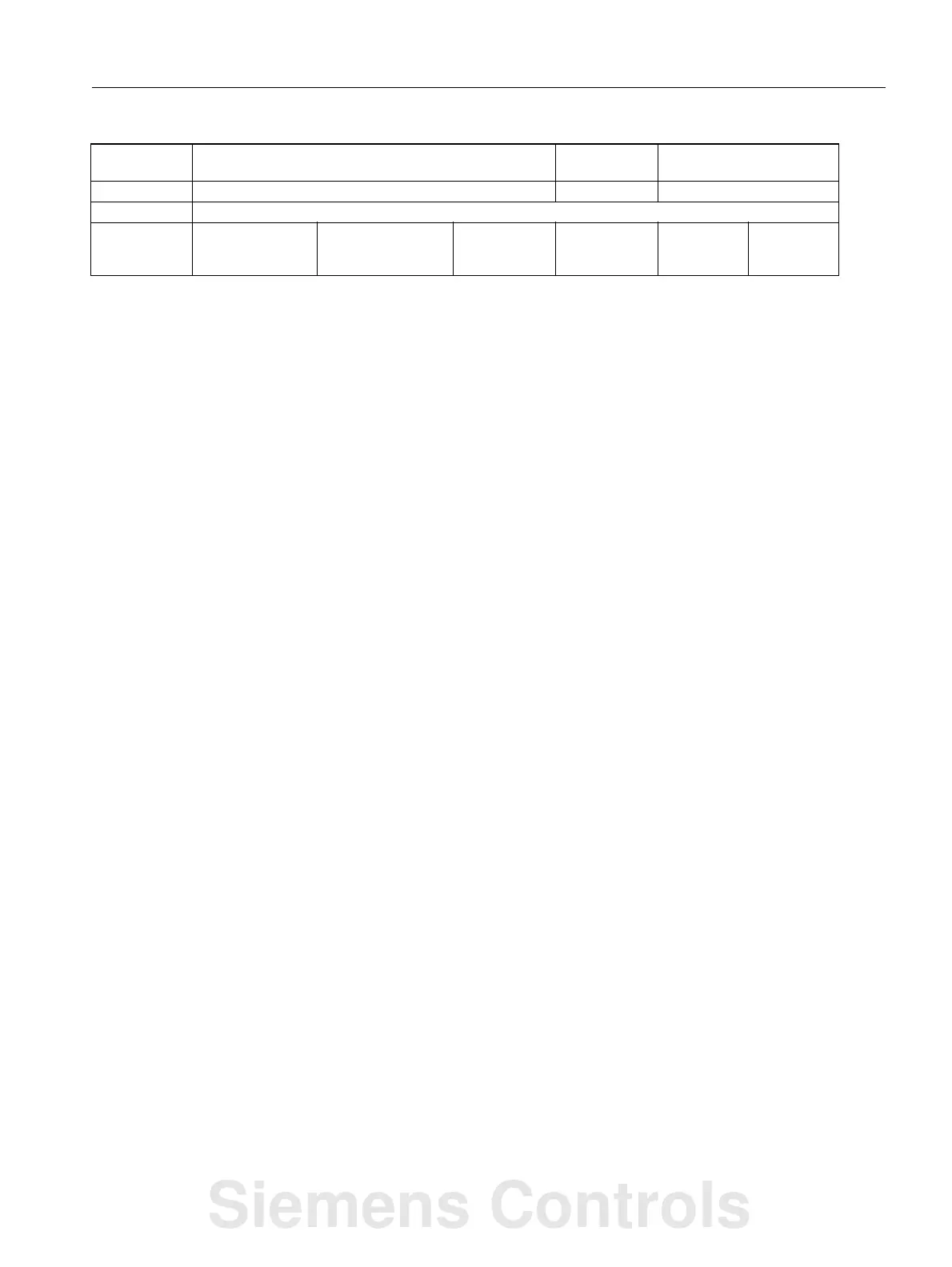

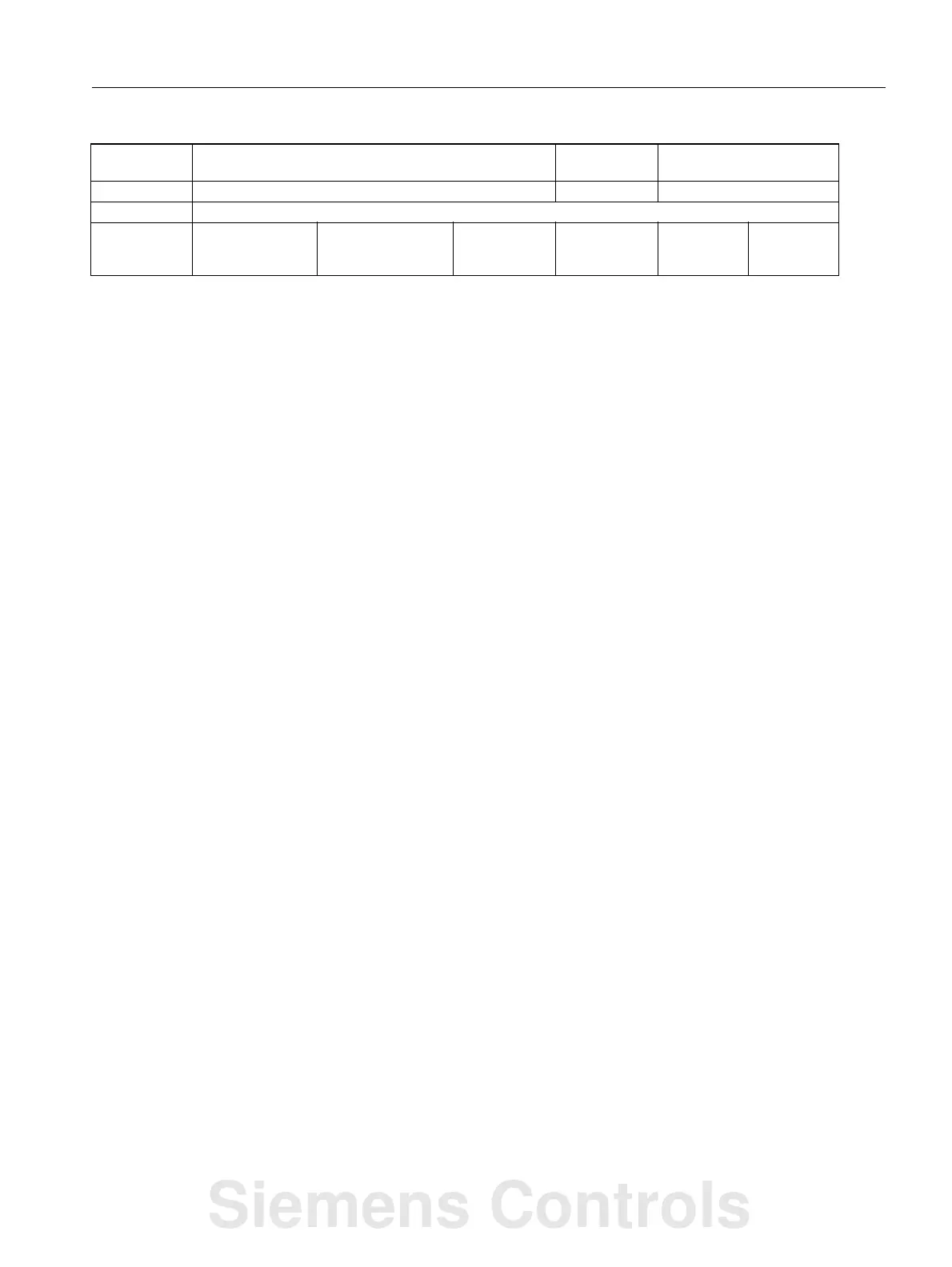

20110 RESET_MODE_MASK C11, C03 F2,K6,M3,TE4,W5,B3,K5,M1,

G2,K1,K2,P1,S1,W1,2.4,2.7

- Definition of basic control settings after reset/PP end DWORD Reset

-

- - 0x4045, 0x4045,

0x4045, 0x4045,

0x4045...

0 0x7FFFF 1/1

Siemens Controls

Loading...

Loading...