Connecting

5

5.1 interfaces

Overview

The relevant interfaces for cabling the control desk are located on the rear side of the machine

control panel.

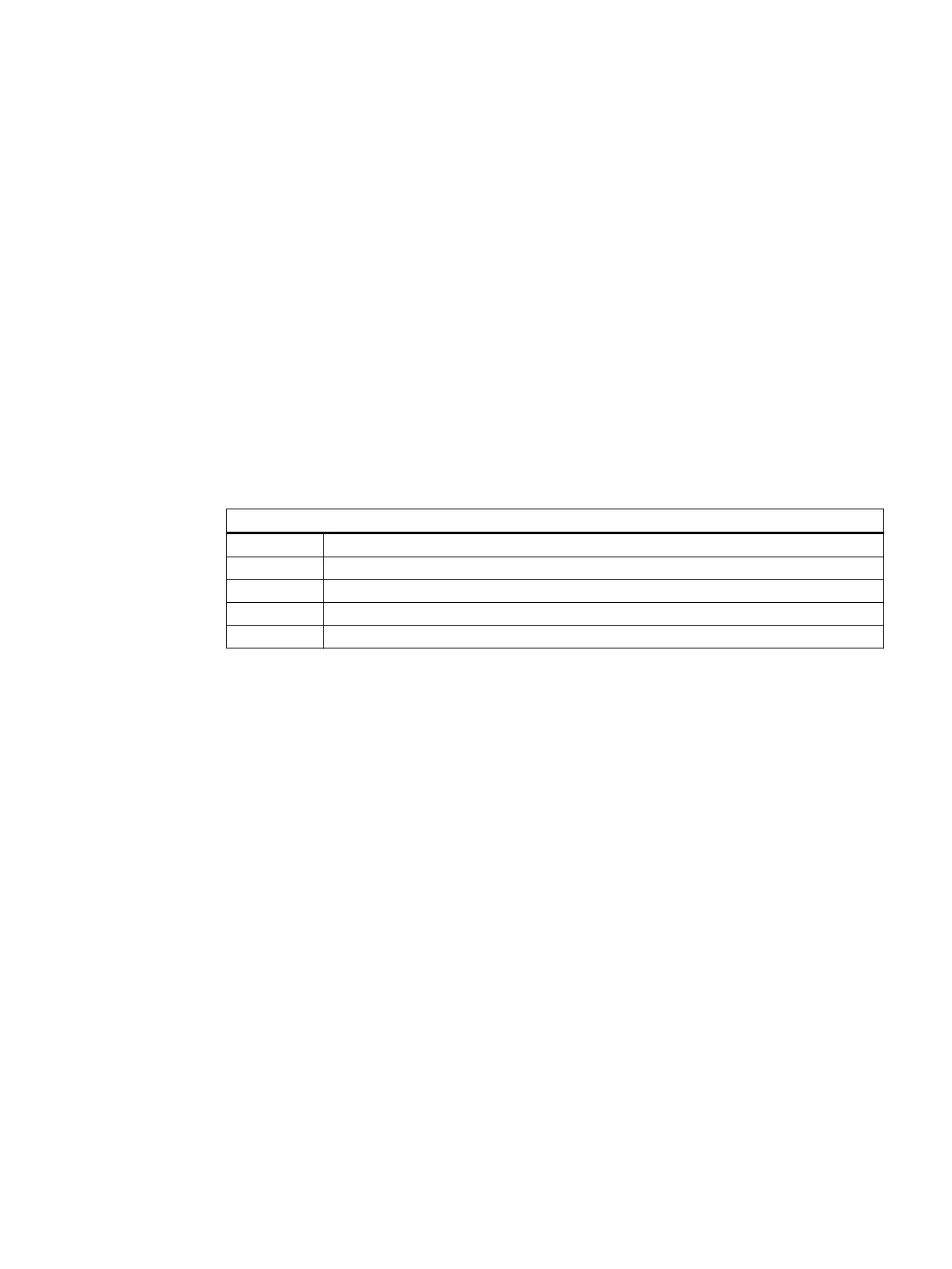

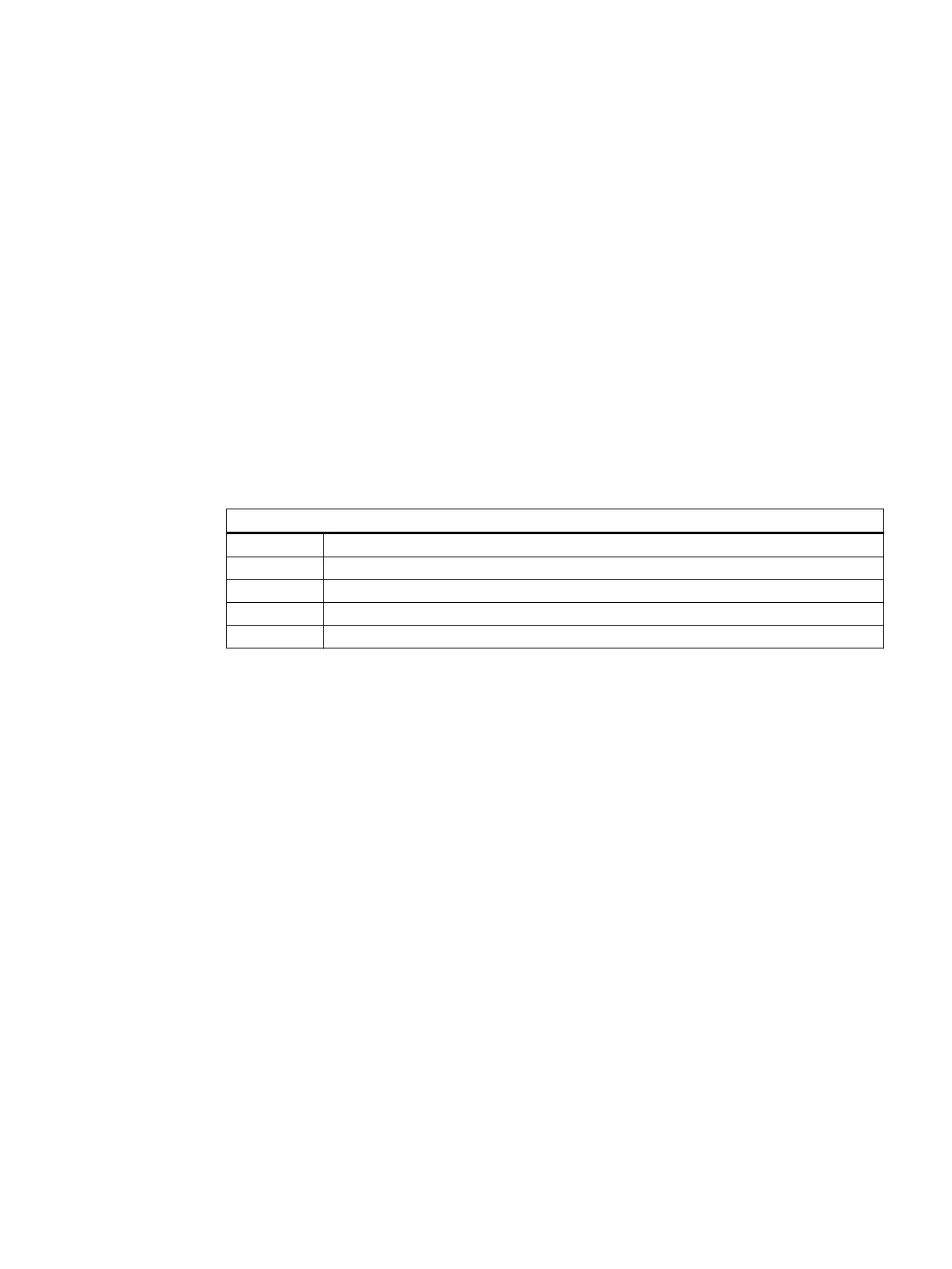

Pin assignment of the interfaces

The pins of the component interfaces are assigned as specied in the tables below. Any

deviations are indicated at the relevant point.

Signal type

I Input

O Output

B Bidirectional (inputs/outputs)

V Power supply

- Ground (reference potential) or N.C. (not connected)

5.1.1 General requirements for the equipotential bonding

Potential dierences must be reduced through the use of equipotential-bonding cables to the

extent that the aected electronic components function awlessly. You must therefore observe

the following information when setting up the equipotential bonding:

• The lower the impedance of the equipotential-bonding cable or the bigger the cross-section

of the equipotential-bonding cable, the greater the equipotential bonding eect.

• If two parts of the system are connected to each other via shielded data cables, with shielding

that is connected at both ends to the grounding/protective cable, the impedance of the

additionally installed equipotential-bonding cable must not exceed 10% of the shield

impedance.

• The cross-section of an equipotential-bonding cable must be dimensioned for the maximum

owing compensating current.

Equipotential-bonding cables with a minimum cross-section of 16 mm

2

are required

between control cabinets.

• Use equipotential-bonding cables made of copper or galvanized steel. Connect the

equipotential-bonding cables via a broad surface area to the grounding/protective

conductor. Protect the equipotential-bonding cables against corrosion.

ONE MCP Part 1: MCP xxxx

Equipment Manual, 07/2020, A5E50324729B AA 33

Loading...

Loading...