Instruction Manual

65

E04819 Issue 1.0

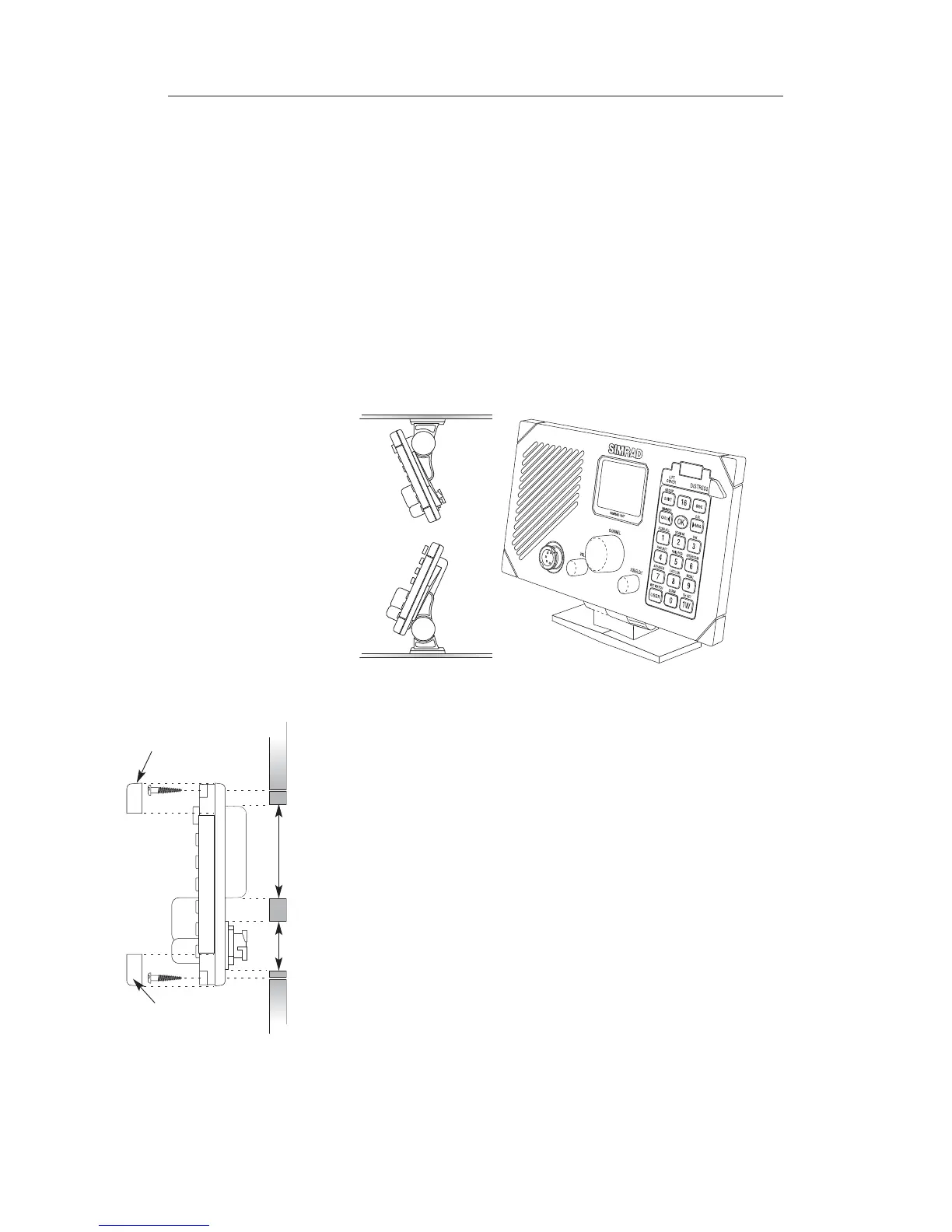

The control panel can be fitted using the adjustable stand sup-

plied or flush mounted onto a bulkhead. The stand (see Fig 7.2

above) allows the panel to be fitted to a flat surface using the

four self-tapping screws supplied and can be inverted for

mounting on an overhead surface.

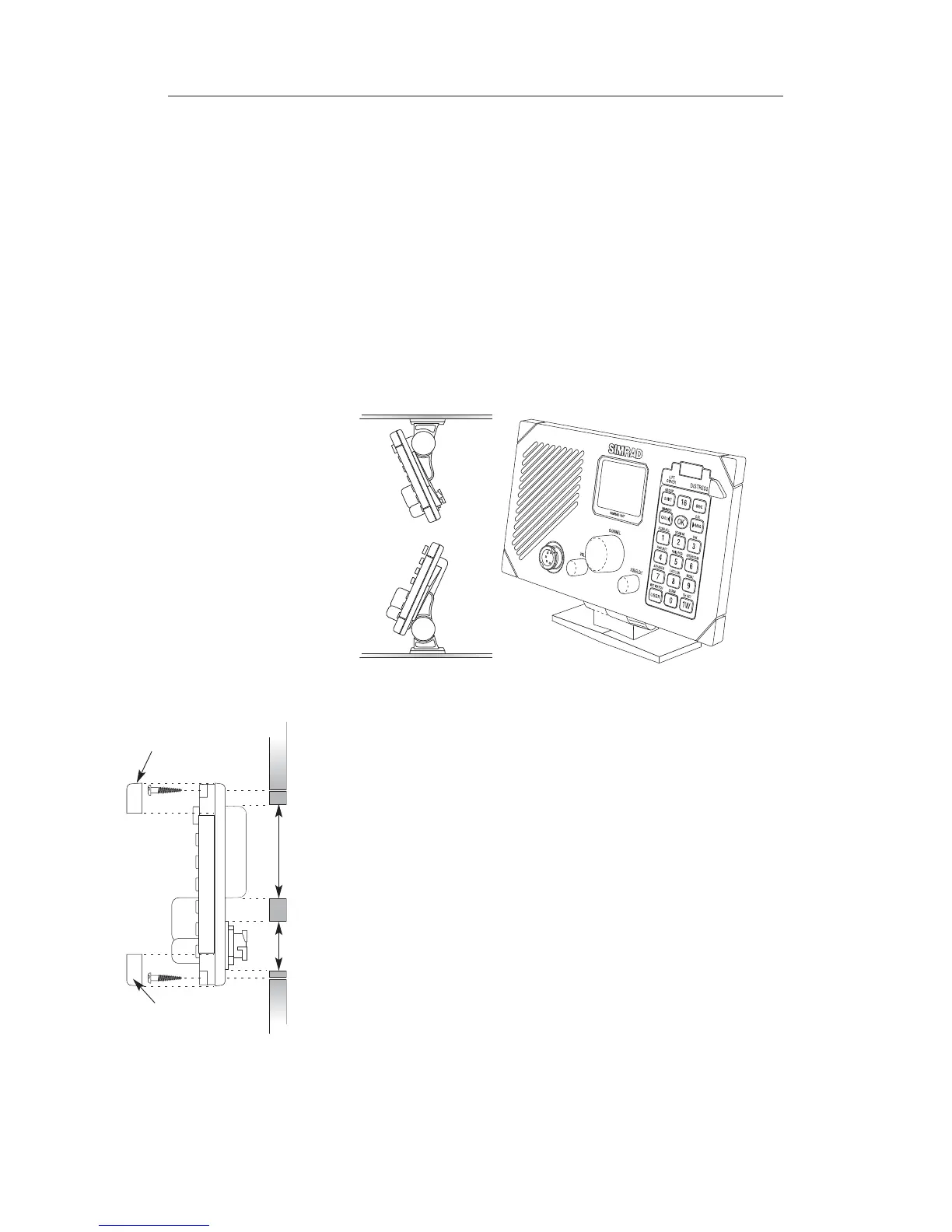

If flush mounting the panel, it is necessary to cut two holes in

the bulkhead – a 50 mm (2 in) hole for the speaker recess and a

28 mm (1.12 in) hole for the rear socket (Fig 7.3). A self-

adhesive drilling template is provided to ensure the holes are

accurately cut. Allow at least 50 mm (2 in) clearance behind the

panel for the interconnecting socket and cable. Remove the cor-

ner mouldings concealing the mounting holes and attach the

panel to the bulkhead using the four self-tapping screws provid-

ed. If fitting to a GRP surface, drill 2.5 mm (0.1 in) pilot holes

for the screws and countersink them to avoid splitting the gel-

coat.

The control panel handset/fistmike socket is waterproof, but if

the control panel is to be fitted in an exposed location (e.g. on

50mm (2.0in)28mm

(1.12in)

Corner

moulding

Corner

moulding

Fig 7.3 - Flush mounting

7.1.2 Control panel installation (RS86)

The control panel should be sited so that engine noise and

vibrations, or other background noise, do not make it difficult

for the operator to hear.

Note As microphones and loudspeakers contain powerful magnets,

the control panel, handset, or fistmike should not be installed

within 1m (3ft 3in) of any magnetic or electronic compasses.

The control panel is connected to the transceiver unit with a

5 m (16.5 ft) cable, therefore the control panel should be fitted

within reach of the transceiver (for longer runs 20 m extension

cables are available as separate accessories; see section 8.6).

Fig 7.2 - Stand mounting control panel

Overhead

mounting

Desktop

mounting

Loading...

Loading...