Operation instructions

SIPOS SEVEN ECOTRON

Page 44 Y070.301/EN

7 Maintenance, inspection, service

7

Maintenance, inspection, service

7�2 Lubrication intervals and lubricants

7�2�1 Lubrication intervals

Perform service or inspection after approx� 8 years (refer to 8.1).

After 50 operating hours or 1 year, regrease coupling shaft A, if available, at the greasing nipple.

For output shaft form A, ensure that the valve stem is greased separately!

These intervals are valid for normal load. When exposed to more intensive loads, the maintenance

intervals are reduced accordingly.

Actuators in high temperature version – add. version T09 – have to be checked for proper condition

by the SIPOS service every 2 years and wear parts have to be replaced!

Whenever the covers and hoods are removed, the seals must be inspected for damage. Replace

and regrease if necessary.

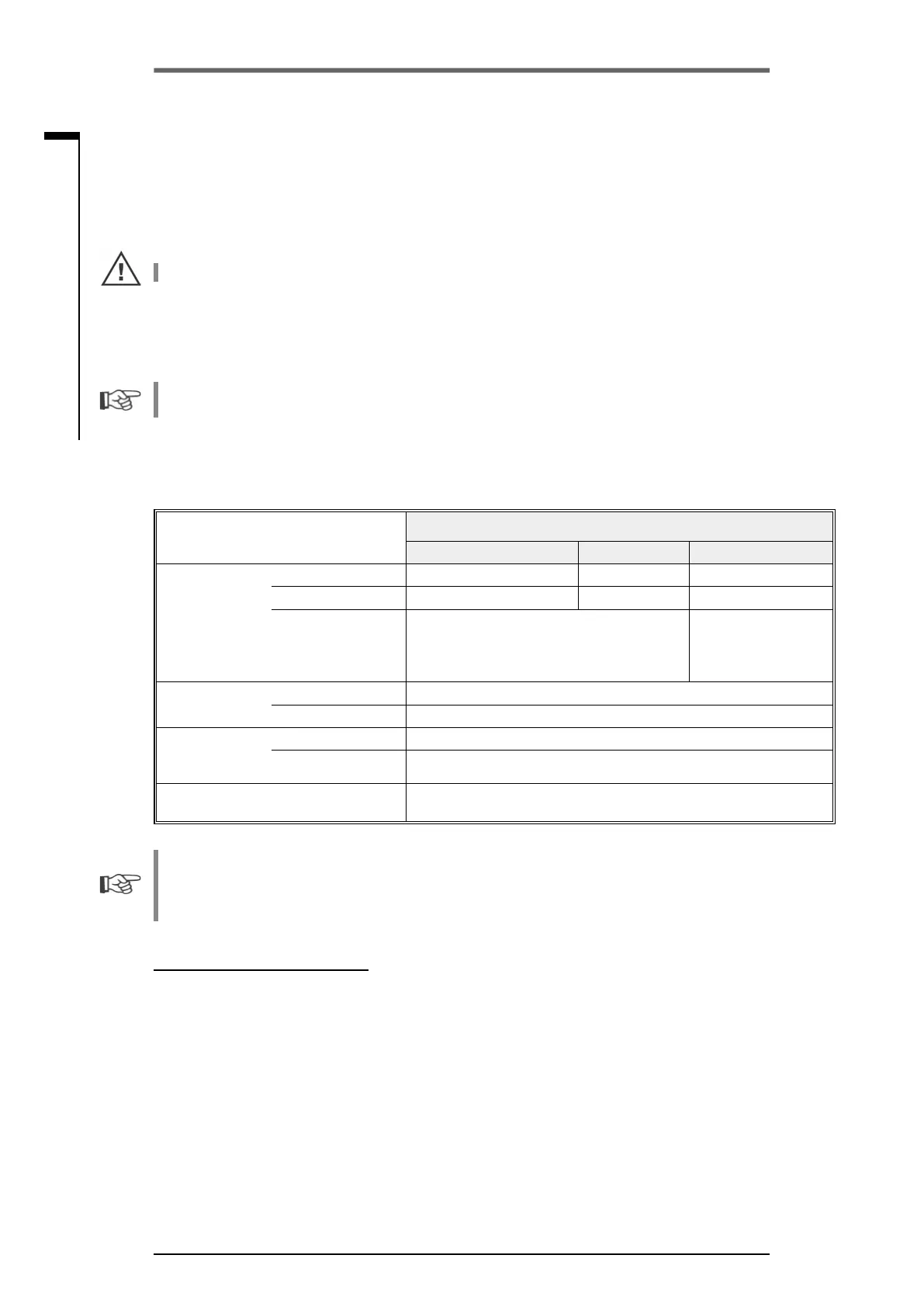

7�2�2 Lubricant assignment and quantity:

Actuator type

2SA7.1/2 2SA7.3/4 2SA7.5/6/7/8

Gear oil

Lubricant quantity 760 cm

3

1,600 cm

3

2,400 cm

3

Filling level

1

max. 46 mm max. 58 mm 23 – 27 mm

Lubricant

2

Klübersynth GH 6 – 220 N (by Klüber)

3

or

Alphasyn PG 220 Polyglycol (by Castrol),

Berusynth EP 220 (by Bechem),

Panolin EP gear synth 220 (by Kleenoil).

Mobil SHC Gear 220

3

(refer to identication

at the equipment)

Other lubrication

points

4

Lubricant quantity 50 cm

3

Lubricant

2

Lubrication grease AR1 (ZEPF)

Output shaft type

A

5

(2SA7)

Lubricant quantity 2 cm

3

Lubricant

2

Commercial ball bearing grease

2SG7..., 2SQ7...

part-turn actuator

virtually maintenance-free (The recommendations for the actuators

should also be observed here.)

■

The manufacturer's instructions and relevant regulations are to be observed when handling and

disposing of lubricants. Technical information concerning lubricants is available on request.

■

Before using a new alternative lubricant (other than the lubricant lled in the factory), the gear

units and gear parts have to be rinsed and cleaned (avoid mixing the oils).

1

Measured from the lubricant surface to the external wall of the housing at oil lling screw.

2

Ambient temperature range -20 – +60 °C.

3

Lubricant used in the factory.

4

e.g. sealing rings, gear systems, bearings, feather keys, uncoated surface etc.

5

If applied.

Loading...

Loading...