35

Visual and daily maintenance inspections Section 4 – Inspections Before Operation

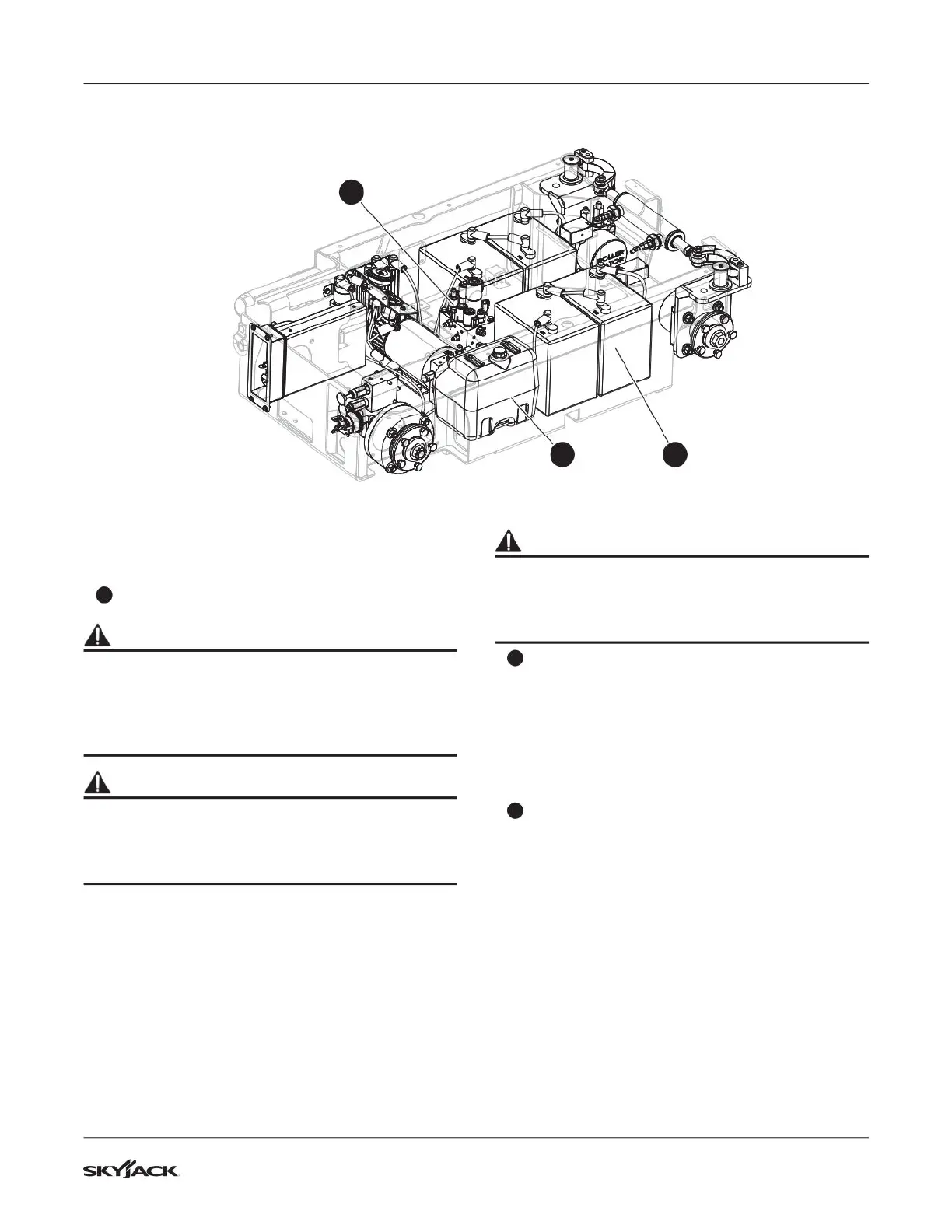

4.2-7 Hydraulic/electrical compartment

Open the hydraulic/ electrical compartment refer

Section 6.5. Do the inspection that follows:

1

Batteries

WARNING

Explosion hazard. Keep ames and sparks away.

Do not smoke near the batteries. Batteries release

explosive gas while you charge them. Charge the

batteries in a well-ventilated area. If you do not

obey, there is a risk of death or serious injury.

WARNING

Corrosion hazard. Do not touch battery acid. Wear

the correct PPE. If the battery acid touches you,

immediately ush the area with cold water and get

medical aid.

1. Do an inspection of the battery case for

damage.

2. Make sure all the battery connections are

tight.

3. If applicable, do a check on the battery uid

levels. If the plates do not have a minimum

13 mm (1/2 inch) of solution above them, add

distilled or demineralized water.

WARNING

Only use original or manufacturer-approved parts

and components for the MEWP. If you do not obey,

there is a risk of death, serious injury, or machine

damage.

2

Manifold

▪

Make sure all ttings and hoses are correctly

tightened.

▪

Make sure there is no indication of hydraulic

leakage.

▪

Make sure there are no loose wires or missing

fasteners.

3

Hydraulic tank

▪

Make sure the hydraulic ller cap closes

tightly.

▪

Make sure there is no visible damage or

hydraulic leaks.

Hydraulic oil level:

1. Make sure the platform is fully lowered.

2. Do a check on the gauge on the side of the

hydraulic oil tank. The hydraulic oil level must

be at or a small distance above the top mark

of the gauge.

2

3 1

Loading...

Loading...