- 53 -

No.EX##-OMY0004

10.3. Wiring

Caution

●To prevent damage, all power for the SI Unit and modules must be turned off (i.e. de-energized) before

the modules are installed or removed.

●For a protection rating of IP65 to be ensured, sockets that are not used must be closed with M12 covering

caps.

●For a protection rating of IP65 to be ensured, all covering caps must be screwed down correctly after

wiring and setting have been performed.

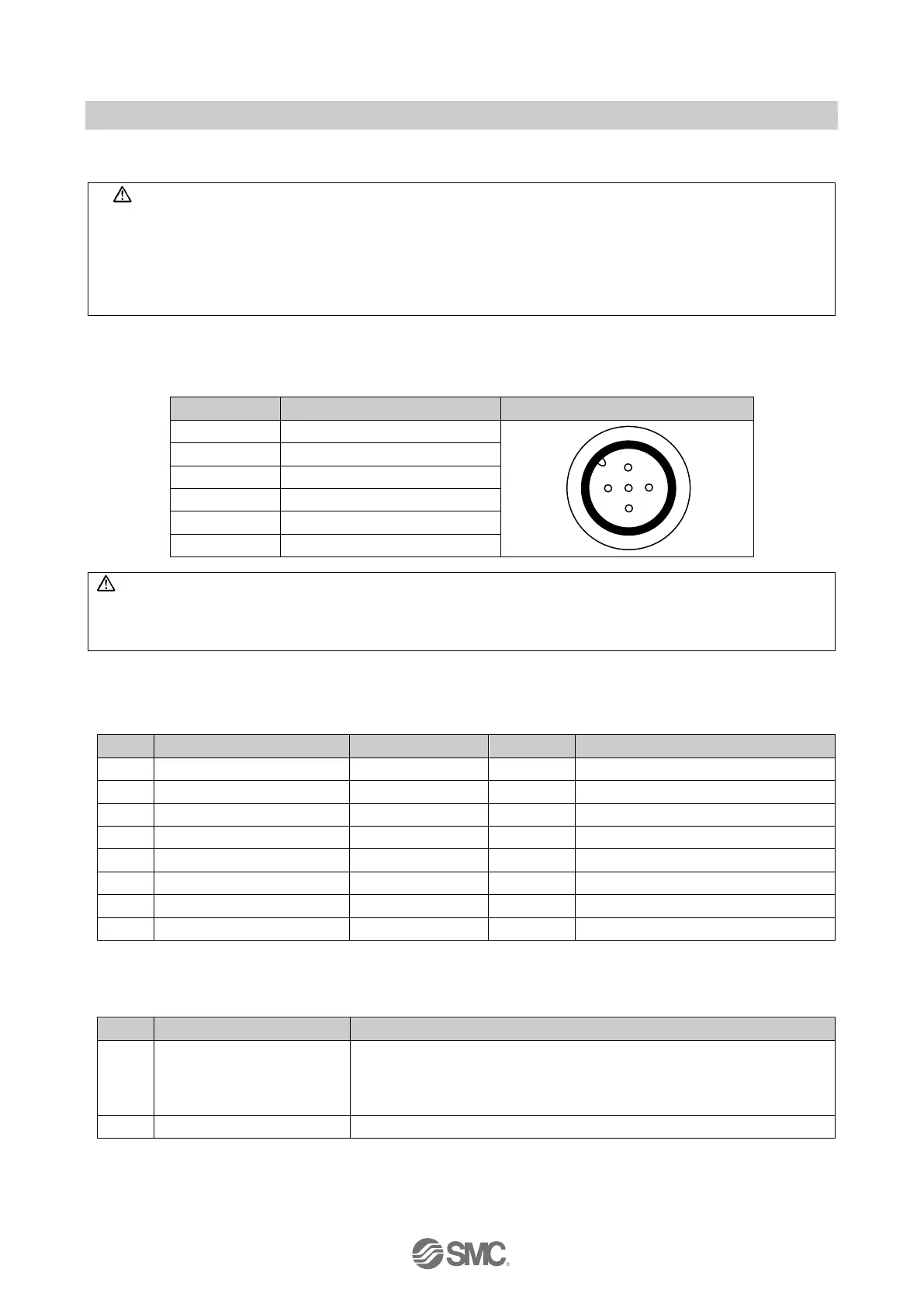

Pin allocation of the M12, 5-way socket connector as shown in the following table:

Table 10-2 Safe input connectors

View of connector (Module side)

WARNING: Loss of safety function

Parasitic voltages can result in the loss of the safety function.

●Connect the sensor ground directly to Pin 3 0V (US1) of the safety module. An external ground may not

be used.

10.4. Safe digital I/O - Safe digital inputs

Table 10-3 Byte 0 Safe digital inputs

Input status of safe input 0

Input status of safe input 1

Input status of safe input 2

Input status of safe input 3

Input status of safe input 4

Input status of safe input 5

Input status of safe input 6

Input status of safe input 7

Note: In case of “1oo2 evaluation”, input status of safe input 4-7 (Byte 0, bits 4 – 7) is fixed to 0: OFF

Table 10-4 Byte 1 Status bits (only applies to Safety Mode (Module Passivation/xxx))

Status bit for

parameterization using

Safety Mode (Module

Passivation/xxx)

0: NOK (Fault state). SI unit has not received a process image for the

PROFIsafe parameters or the received process image is invalid

1: OK. Process image for PROFIsafe parameters received and valid.

Byte 2-5: Reserved for PROFIsafe communication container specified by PROFIsafe.

Loading...

Loading...