118-119

Laser Engraving and Cutting

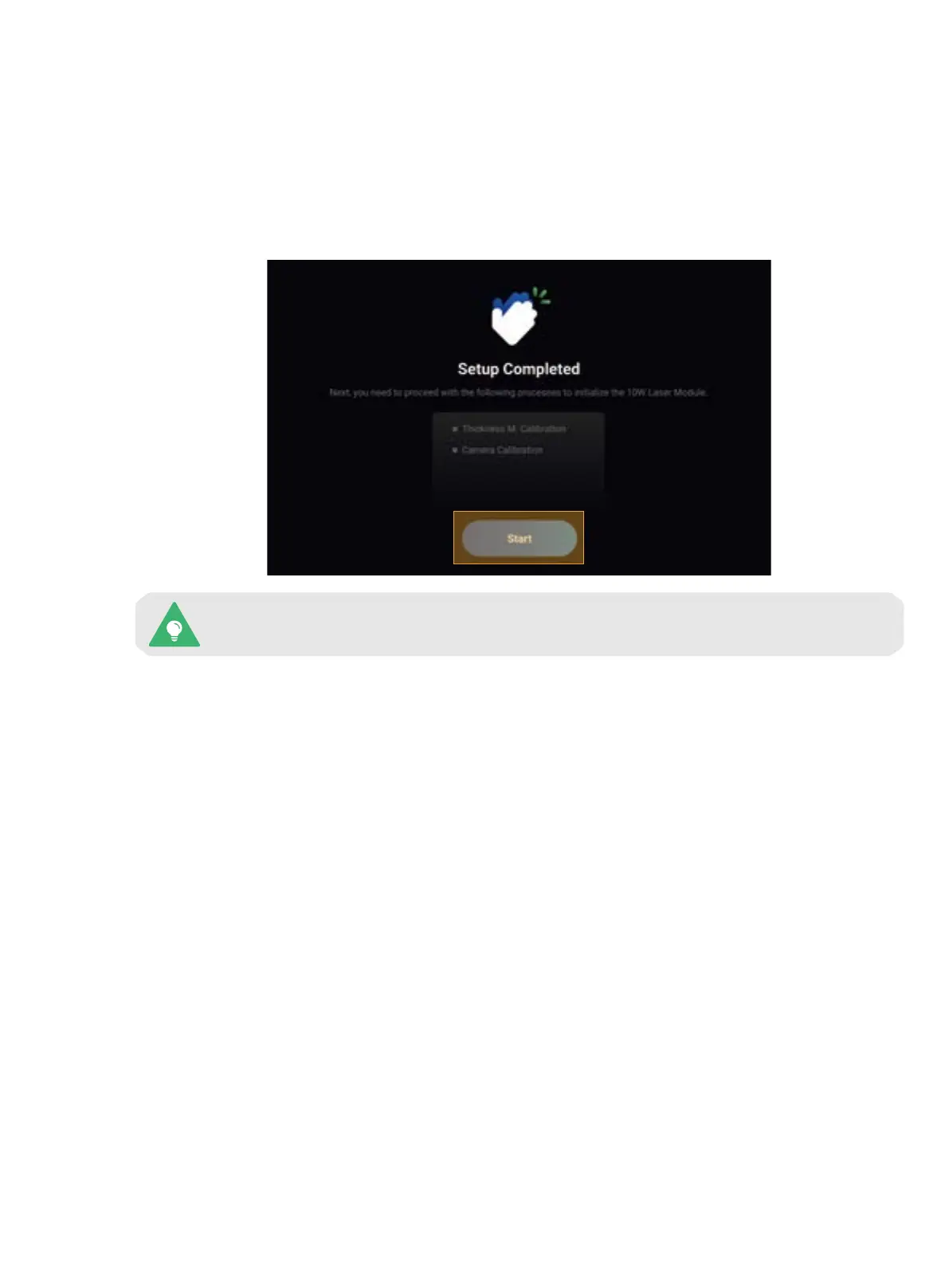

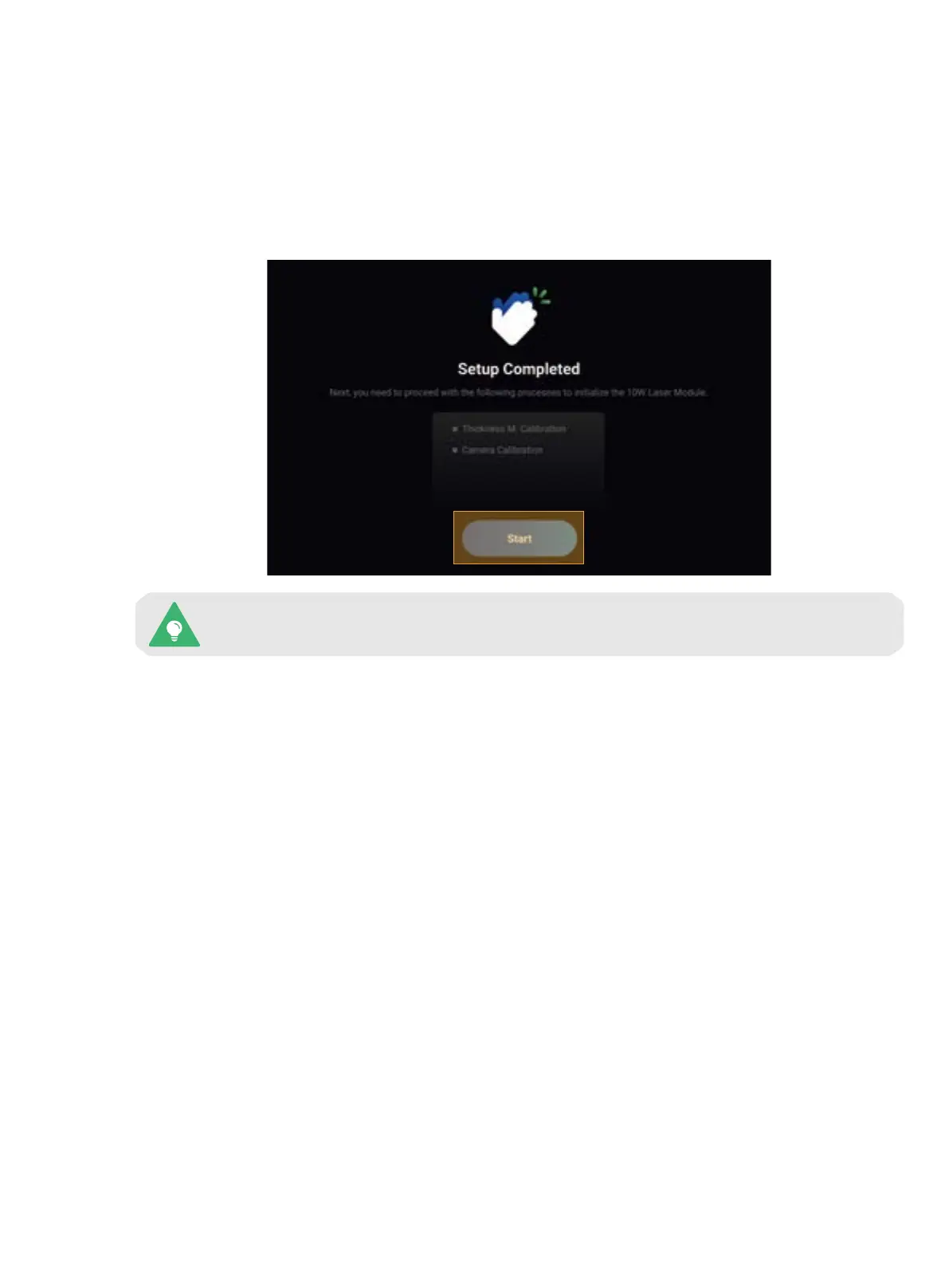

This calibration wizard appears only the first time you use the 10W Laser Module. To redo the

calibrations later, tap Calibration on the Home Screen and select the corresponding process.

5.2.2 Calibrate the 10W Laser Module

For the first-time use of the laser function, the Touchscreen will walk you through the necessary calibrations so

that the 10W Laser Module can work properly.

The laser calibration wizard consists of two processes: Thickness Measurement Calibration and Camera

Calibration. Before you start the calibration, we recommend that you read this section to learn about each

process.

1. Thickness Measurement Calibration

Brief Introduction

The 10W Laser Module features a thickness measurement system that uses the triangulation technique. The

system includes a red laser emitter that projects a red dot on the material surface and a camera that captures

the red dot image to calculate the material thickness.

How It Works

The Thickness Measurement Calibration adjusts the parameters in the thickness measurement system to

ensure accuracy. In this process, a laser calibration plate with known thickness is first used to help the machine

determine the height of the laser engraving and cutting platform and then as a measured object to calibrate the

system parameters.

Loading...

Loading...