Maintenance

SPECTROLAB — 30.07.2015 — 27

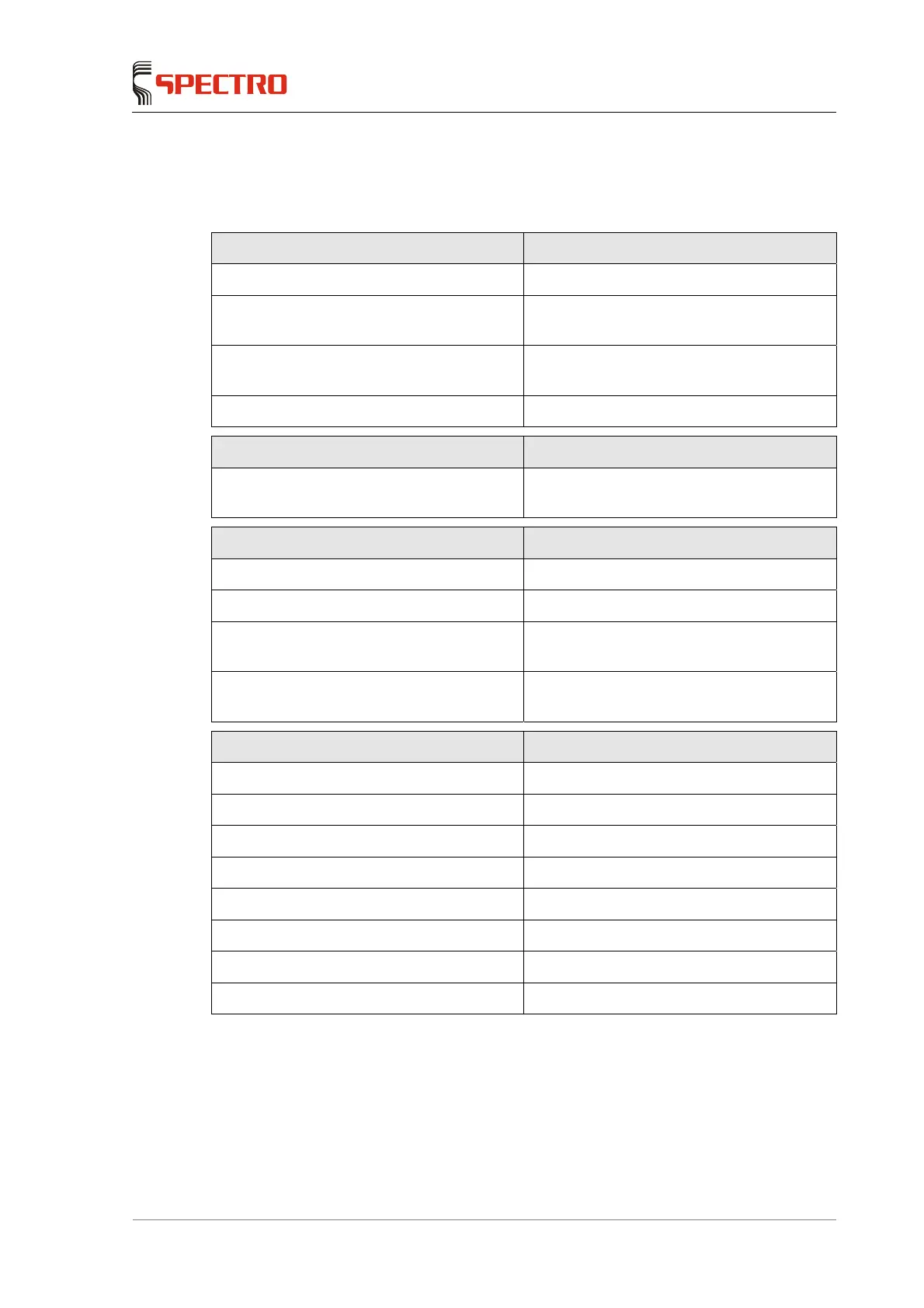

7.3 General Maintenance

Start of work Necessary tasks

1. Check the argon supply. The min. pressure in the bottle is 10 bar.

2. Diagnosis system - maintenance or

check the number of measurements.

Will be specified by the diagnosis system.

3. Check the water level in the gas-

washing bottle.

Top up/replace, see page 40.

4. Check the burn spot. Visual inspection

After every measurement Necessary tasks

Clean the electrode.

Use the small wire brush to clean the

electrode.

Monthly maintenance work

Change water in gas-washing bottle. See page 40.

Clean the light inlet window of the optics. See page 28.

Clean the light inlet window of the optional

air optics.

See page 29.

Clean the filter mats and replace if

necessary.

See page 41.

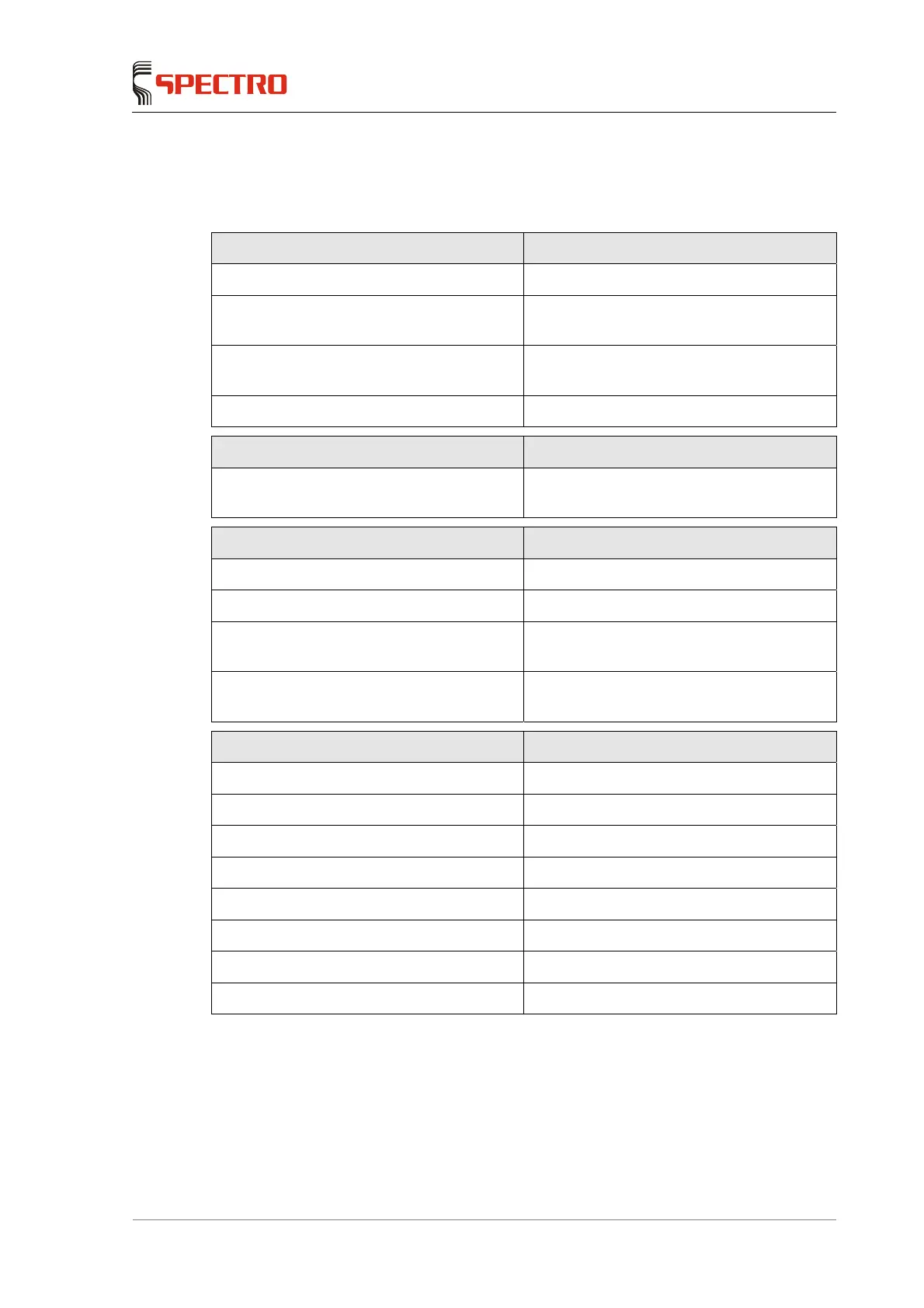

As required

Replace standardization samples. See page 37.

Replace the re-profiling samples. See page 37.

Re-profiling the optics. See page 23.

Standardizing the measuring device. See page 23.

Replacing the iCALization sample. See page 37

Clean spark stand. See page 31.

Clean/replace the insert of the filter bottle. See page 39.

Replace the filter bottle. As required.

Loading...

Loading...