30 Maintenance KGE/EN (1711) 6.5

• Make sure appropriate grade and amount of lubricant is present in bearings and in the

oil chamber of the mechanical seal.

• Check bearings for excessive wear. Worn bearings may result in excessive shaft run-

out necessitating frequent seal failure.

• Always ensure that the liquid level in the suction line is adequate. Never allow the

suction head to drop below the minimum NPSH (required) by the pump.

• Check motor for accumulation of dust or dirt, which might influence motor

temperature.

6.4 Flushing

Because the pump could have been used for corrosive or poisonous liquids, it should

first be thoroughly rinsed out. Flushing the pump out is necessary because the origin of

the liquid which it contained is not always known and, even after draining the pump,

liquid can remain inside.

• Present connections can be used to flush the pump out.

• During this flushing procedure, observe adequate safety regulations and take

environmental protection measures. The wearing of gloves and safety glasses to

protect against possible splashes and hot temperatures is advised.

6.5 Ball Bearings

The ball bearings are sealed and packed with grease, relubrication is not necessary. The

lifetime of the bearings of the most heavily loaded pump is 10.000 running hours, and for

the lightest loaded pump it is six times longer.

The lubrication of the bearings plays a very important role and therefore it is

recommended to replace the bearings after 10.000 hours of service, or every three

years.

6.6 Electrical installation

Maintenance operations on the electric installation may be performed only by trained and

qualified personnel and after disconnecting the electric power supply. Carefully follow

the national safety regulations. Respect the above mentioned regulations also if

performing work while the power supply is still connected.

6.7 The oil chamber

Before start-up the lip seal chamber must be filled with a lubricating liquid which will not

attack the liquid to be pumped nor the mechanical seal (normally the chamber is filled

with oil of type SAE 20). Every 2000 hours of running, or once a year, drain and refill with

fresh oil.

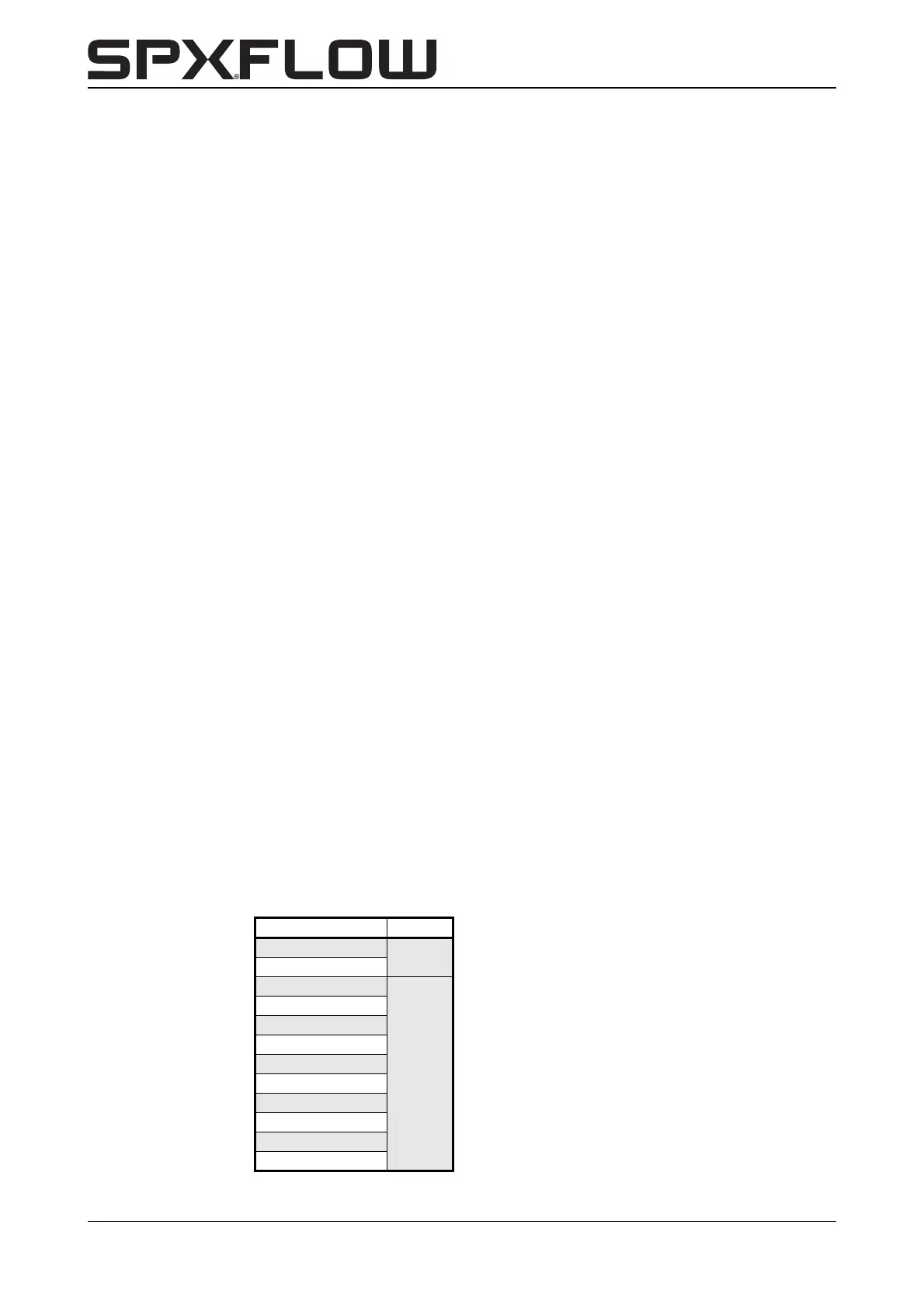

Table 5: Oil chamber contents.

pump size [l]

KGE 11-3

0,22

KGE 11-4

KGE 16-3

0,6

KGE 12b-5

KGE 12-5

KGE 12-6

KGE 15-6

KGE 16-6

KGE 14-8

KGE 18-4

KGE 20b-5

KGE 22-6

Loading...

Loading...