KGE/EN (1711) 6.5 Disassembly and assembly 35

KGE

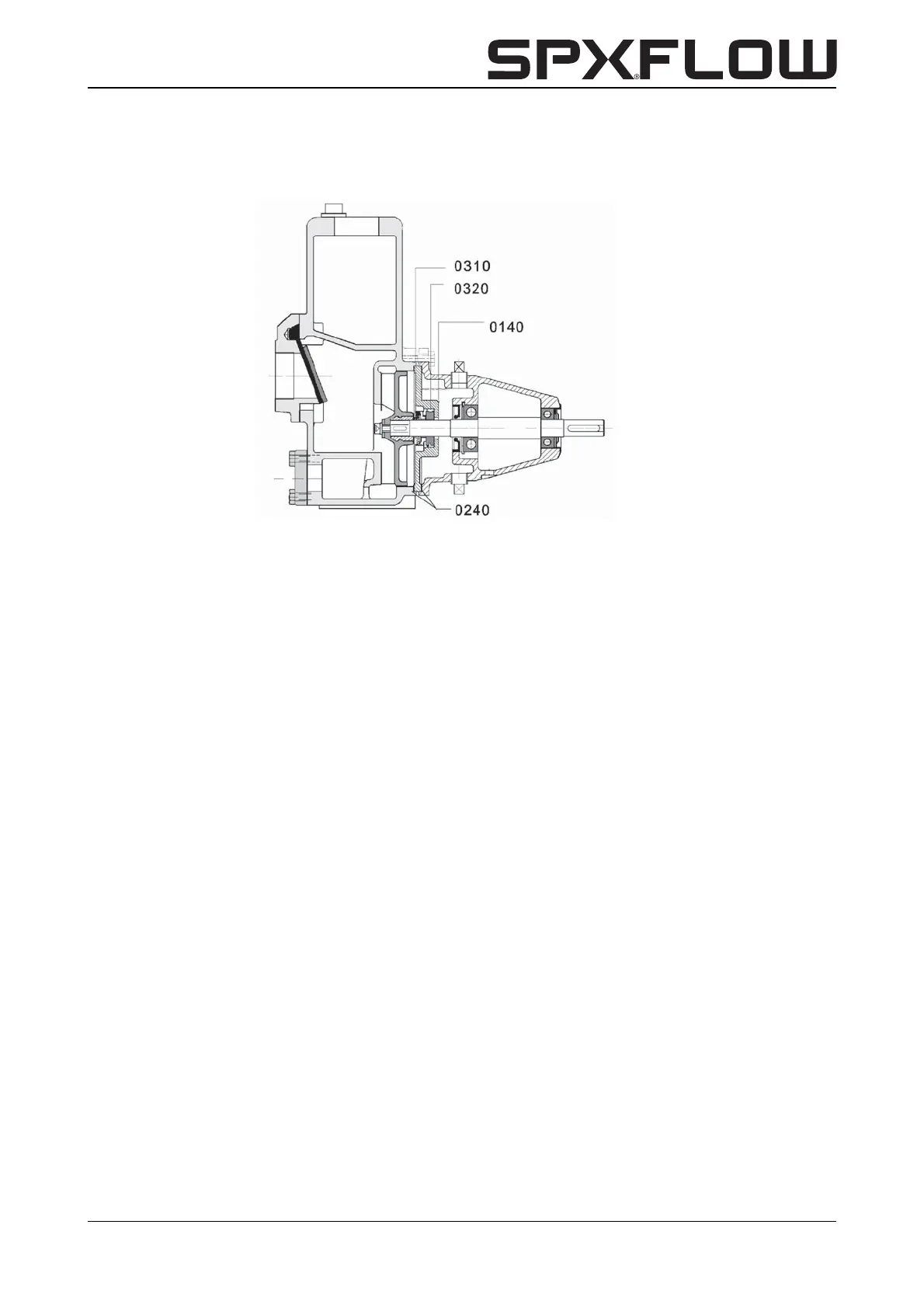

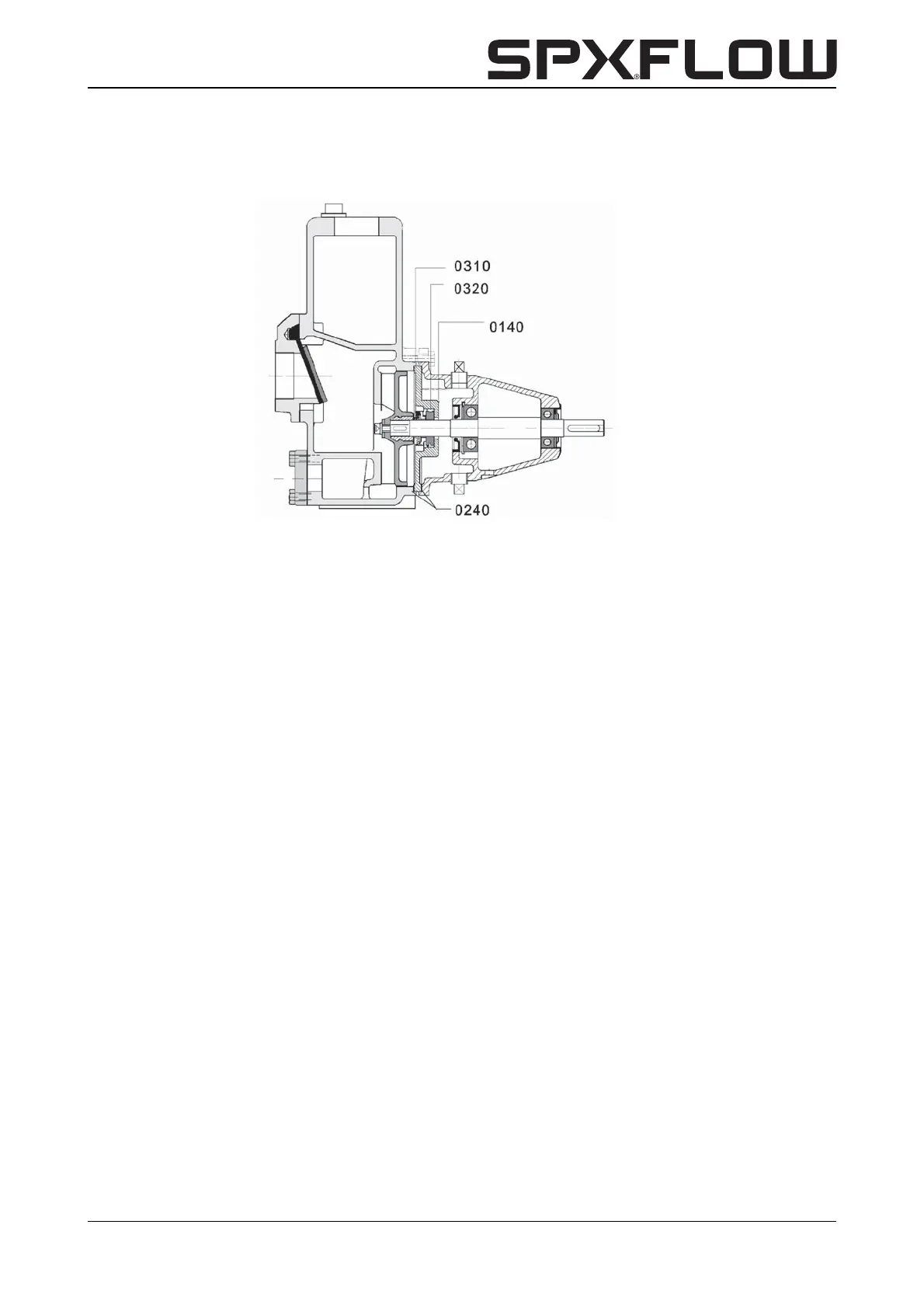

7.3 Replacement of mechanical seal

7.3.1 Disassembly of mechanical seal

1 Follow steps 1 to 4 of the impeller dismantling procedure.

2 Now remove the rotating part of the shaft seal (0310) fitted to the shaft.

3 Pull the intermediate cover (0140 / 0120) from the bearing bracket.

4 Push the counterseal ring (0320) of the shaft seal from the intermediate cover.

5 Replace the gaskets (0240 / 0440).

7.3.2 Assembly of single mechanical seal

Follow steps 4 to 1 of the disassembly instructions. Please ensure to apply few drops of

SAE20 oil between the seal faces and also on outside surface of the ‘L’ / ‘T’ - or Seal-

ring (bearing bracket group 0 and 00:) O-ring.

7.4 Replacement of the bearings

The ball bearings are sealed and grease-packed, so they are lubricated for life.

7.4.1 Disassembly of the ball bearings

1 Disassemble the impeller and shaft seal. Please refer to the disassembly instructions.

2 Disassemble the ball bearing cover (1110 / 2330), the inner circlip and the laminated

seal (second bearing cover) or BA-ring.

3 Strike the shaft on impeller side such that the shaft and bearings are released from

the bearing bracket.

4 Remove the ball bearing along the shaft end side, using a coupling puller.

5 Remove shoulder rings out of the bearing bracket (: bearing bracket 1 & 2: from

the shaft)

6 Clean the shaft properly on impeller side, particularly where the shaft seal is

positioned, then remove the ball bearing on impeller side.

Figure 13: Mechanical seal disassembly bearing bracket group 0 and 00

Loading...

Loading...