KGE/EN (1711) 6.5 Disassembly and assembly 33

KGE

7 Disassembly and assembly

7.1 General

• When servicing the pumps, see to a clean working environment because certain parts,

say, the mechanical seals, are extremely vulnerable, other parts having close

tolerances. Check that the parts have not been damaged in transit. In particular,

inspect the spigots mating and sealing faces, etc.

• Loctite liquid securing type 243 is used for securing the impeller screw or impeller

bolt.

When Loctite is used, first degrease the parts properly. The Loctite must be applied in

sufficient quantities both internally and externally and the bolts tightened up to the torque

settings shown in table below:

7.2 Replacing the impeller

Also refer to sectional drawings

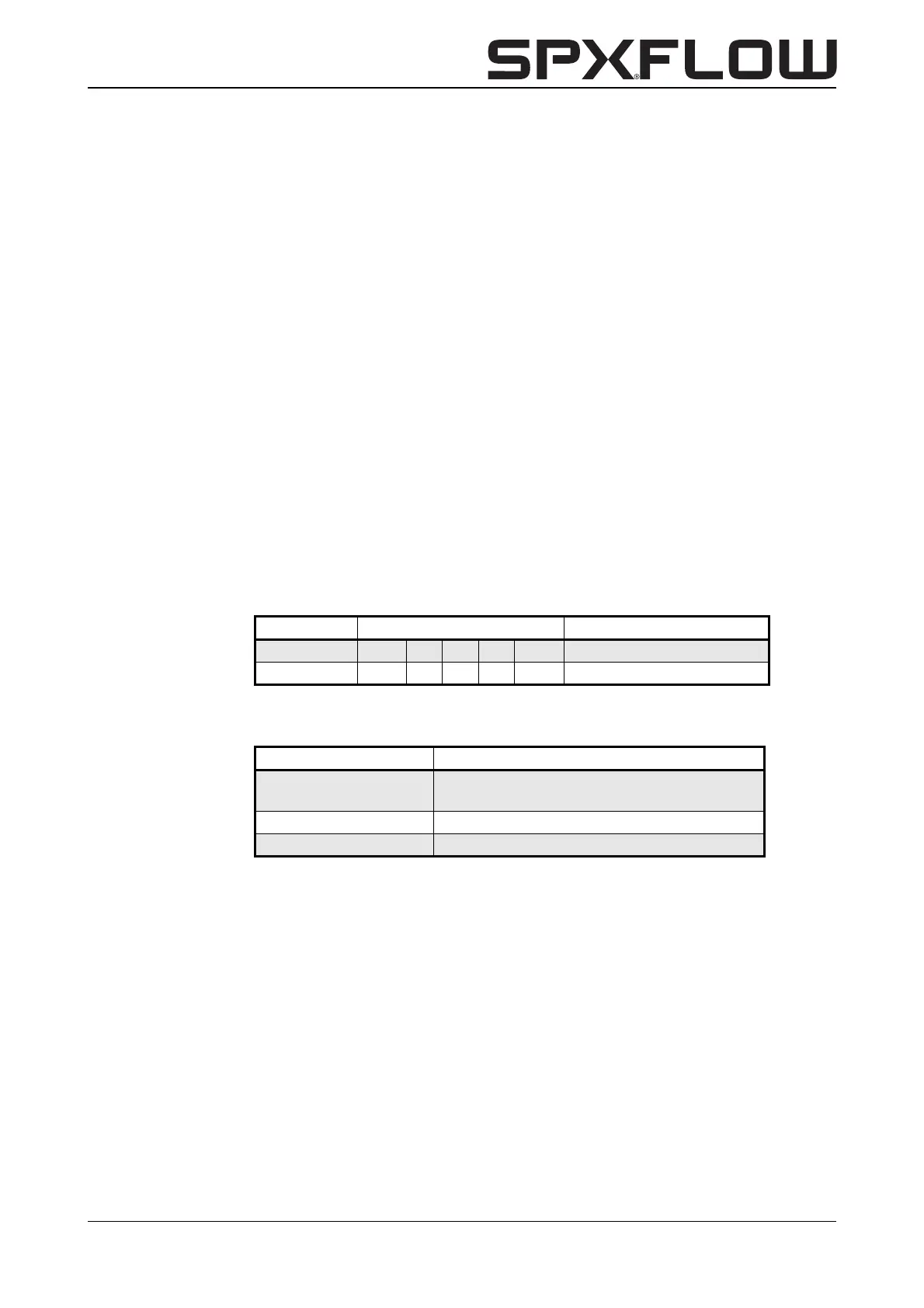

Material bolt Max. tightening torque Nm Application

8.8 11 25 51 87 215 Bearing bracket, lantern piece

A2 / A4 8,5 21 42 70 173 Impeller

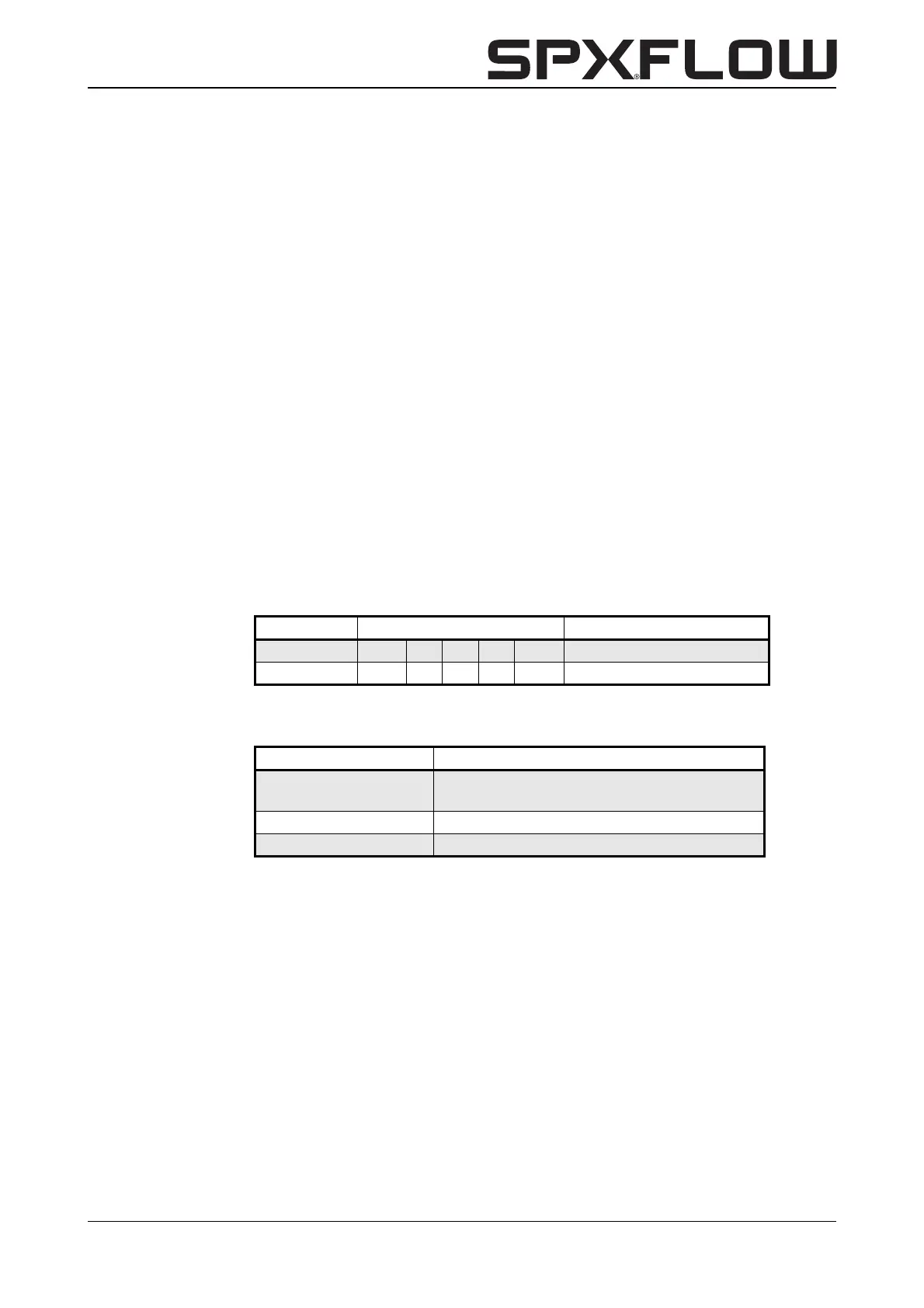

Impeller fixation

Bearing bracket 00

stainless steel bolt with tolerance ring (on KGEF)

or with key (KGE) and washer.

Bearing bracket 0 and 0+ stainless steel bolt with key and washer

Bearing bracket 1 and 2 stainless steel nut with key and washer

Loading...

Loading...