KGE/EN (1711) 6.5 Maintenance 31

KGE

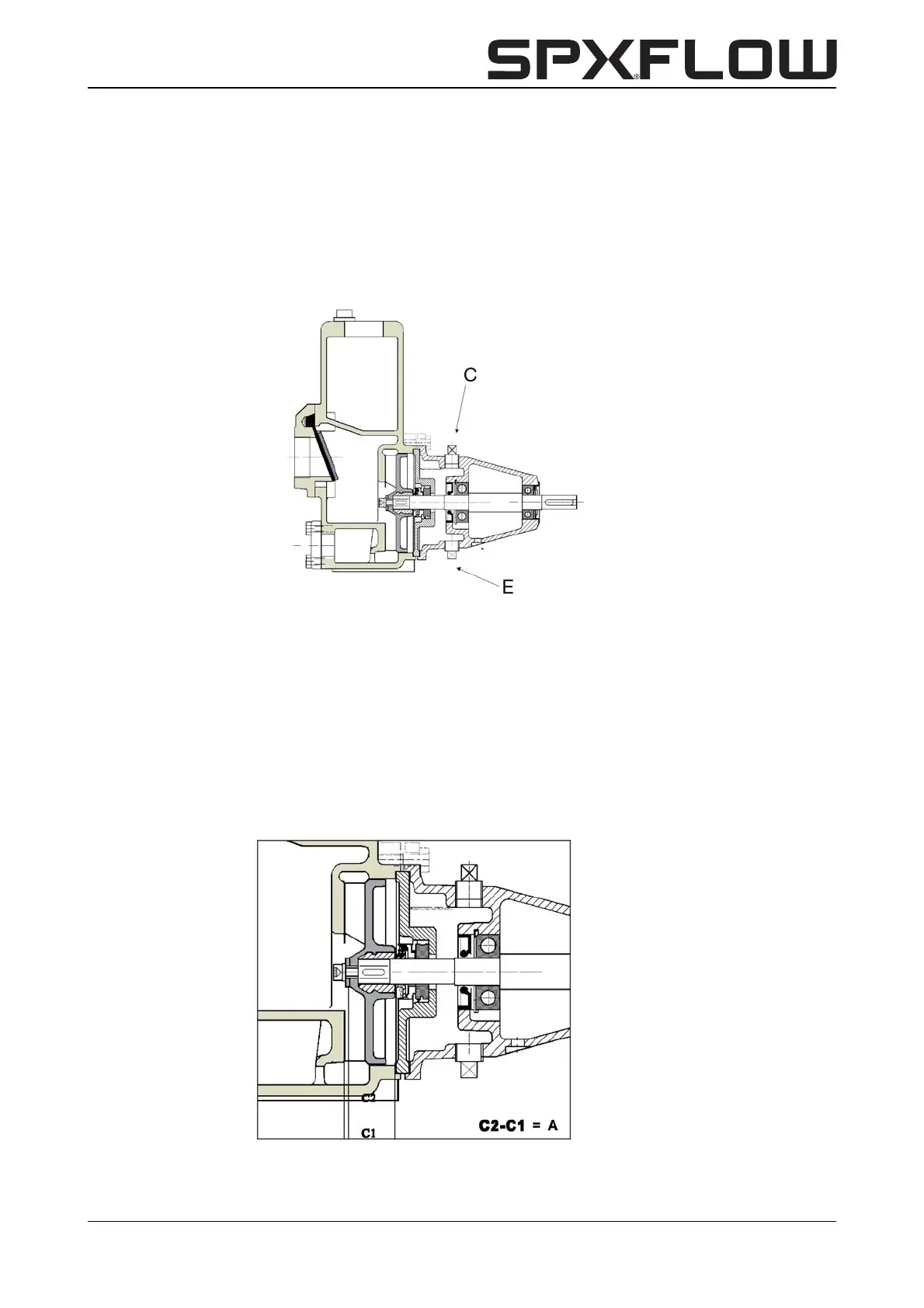

6.8 Mechanical seal

If the mechanical shaft seal should start to leak, the oil chamber will overflow via the hole

in the oil filler cap (C : see figure 10) and the pump must be immediately stopped to

replace the mechanical seal.

6.9 Oil seal

If leakage from (E) is noticed, this indicates the lip seal has failed and needs

replacement.

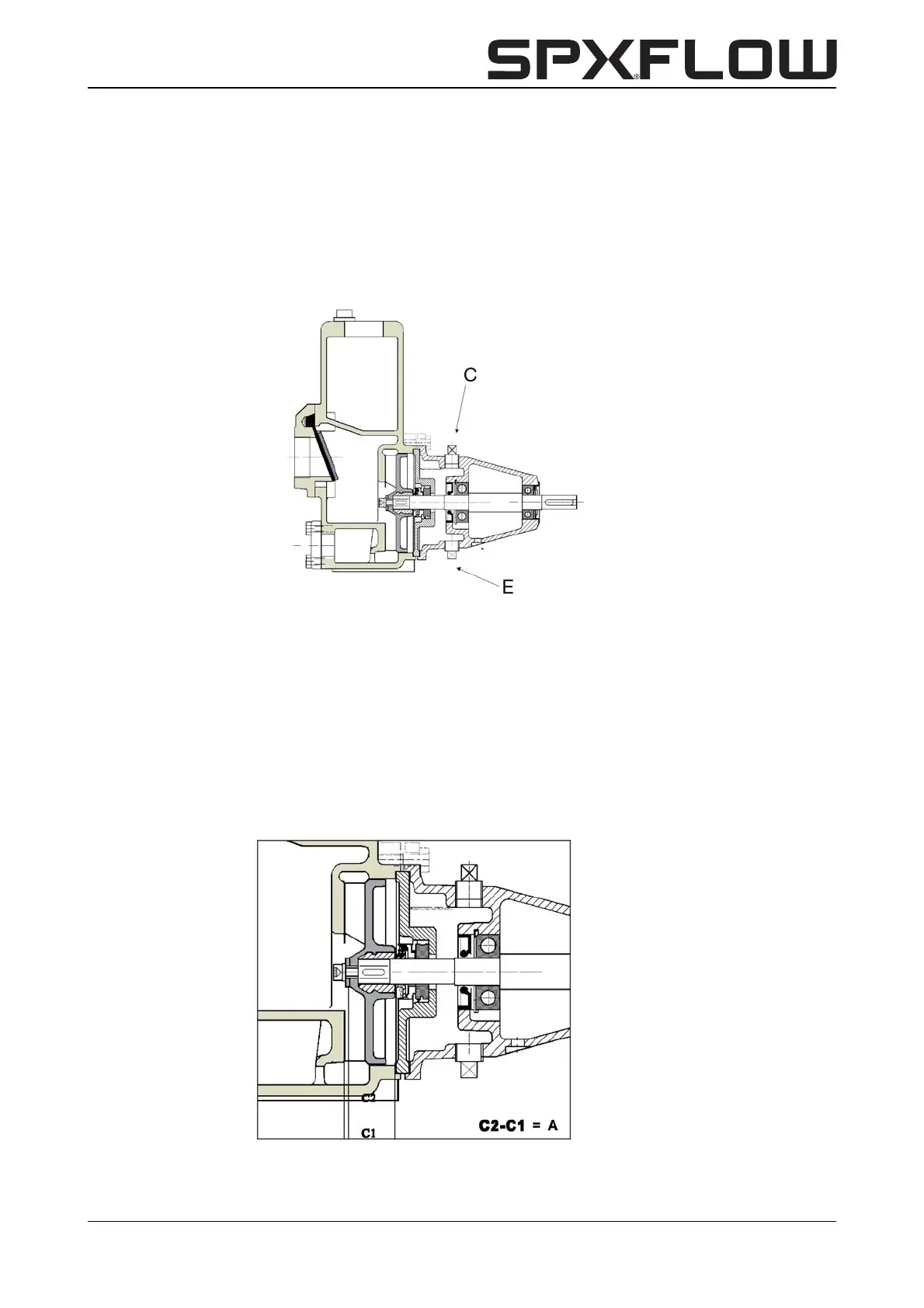

6.10 Impeller

If there is decline in the performance characteristics of the pump when neither the

installation nor the working point have been changed it is 90% certain that there is wear

on the impeller.

How quickly this wear occurs is dependent upon the type of liquid being pumped. There

is a clearance between the impeller and the pump casing. This clearance becomes

greater through wear. In order to check this, the pump must be dismantled and the

dimension A (see figure 11) measured. It must not exceed 0,5 mm.

The dismantling and reassembly instructions are given in the following chapter.

Figure 10:

Figure 11:

Loading...

Loading...