34 Disassembly and assembly KGE/EN (1711) 6.5

7.2.1 Disassembly impeller

1 Drain out the drain liquid from the oil chamber by removing the oil drain plug (1160);

with and : 0830).

2 Bearing bracket 00, 0 and 0+:

• Detach bearing bracket by loosening bolts (0500).

• Undo the impeller screw (0520)

3 Bearing bracket 1 and 2 (see sectional drawings) :

• Detach bearing bracket by loosening bolts (0820)

• Disassemble intermediate cover with bearing bracket from pump casing by loosening

bolts (0770)

• Undo the impeller bolt.

• Remove washer

4 Next detach the impeller (0220) or (0130), using a coupling puller.

7.2.2 Impeller assembly

1 When pushing on the impeller, accurately check that its position is square with the

shaft.

2 When an impeller is assembled with a key (0550), neither the key nor the keyways in

the shaft or impeller must be adjusted.

3 Insert the same number of gaskets (0220 or with bearing bracket 1 and 2: 0440)

between pump casing and intermediate cover, removed during disassembling from

factory fitted pump.

4 Slide the impeller onto the shaft.

5 Take the washer and fit, depending on the construction, the impeller screw, Allen

screw (0520) or impeller bolt with washer, using Loctite 243.

6 Next provide the gaskets (0240) or (0440) in the pump casing and fix the bearing

bracket to it using the Allen screws.

7 In case the oil chamber was emptied, fill it with the specified liquid through plug.

Make sure the plug is fitted.

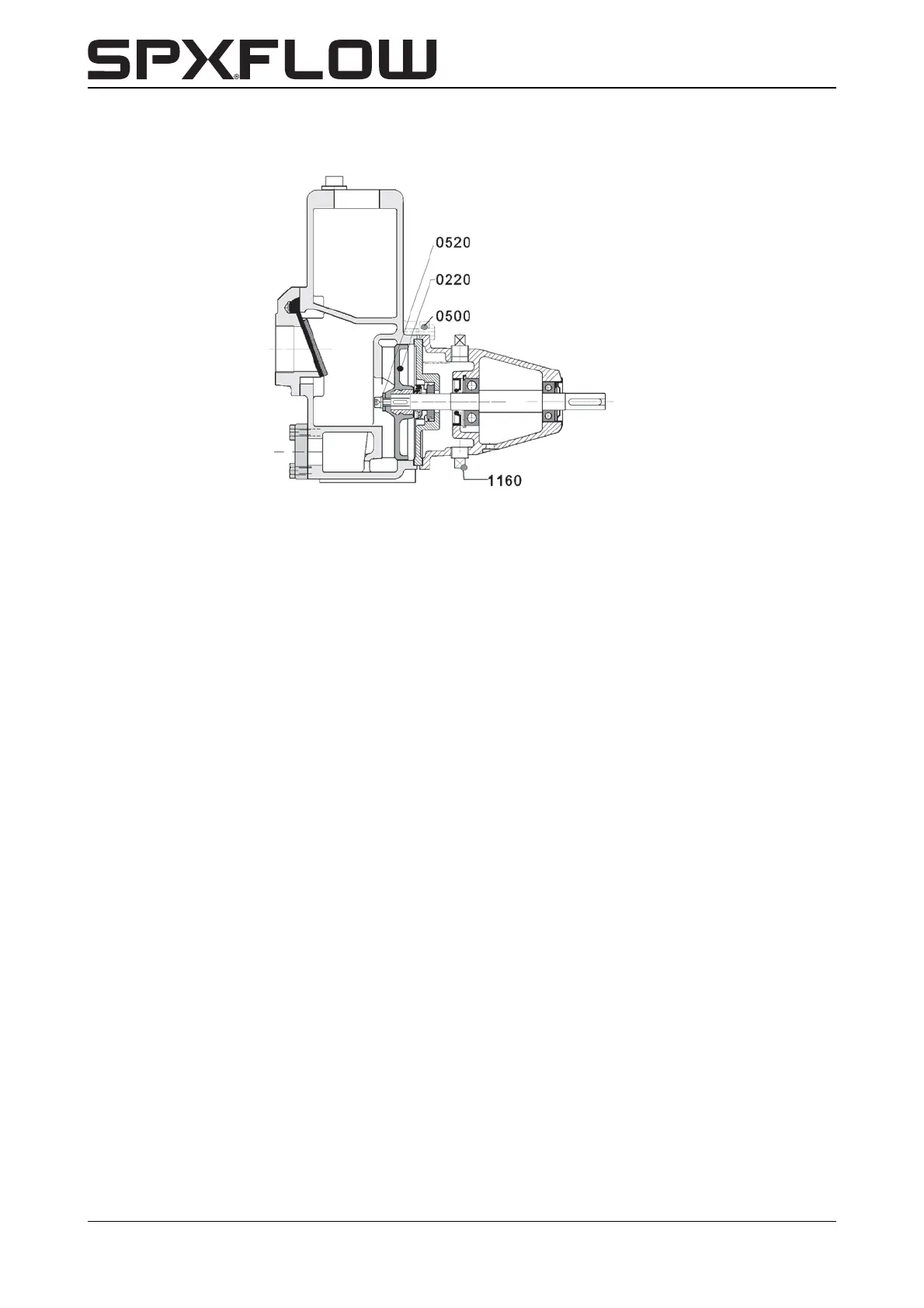

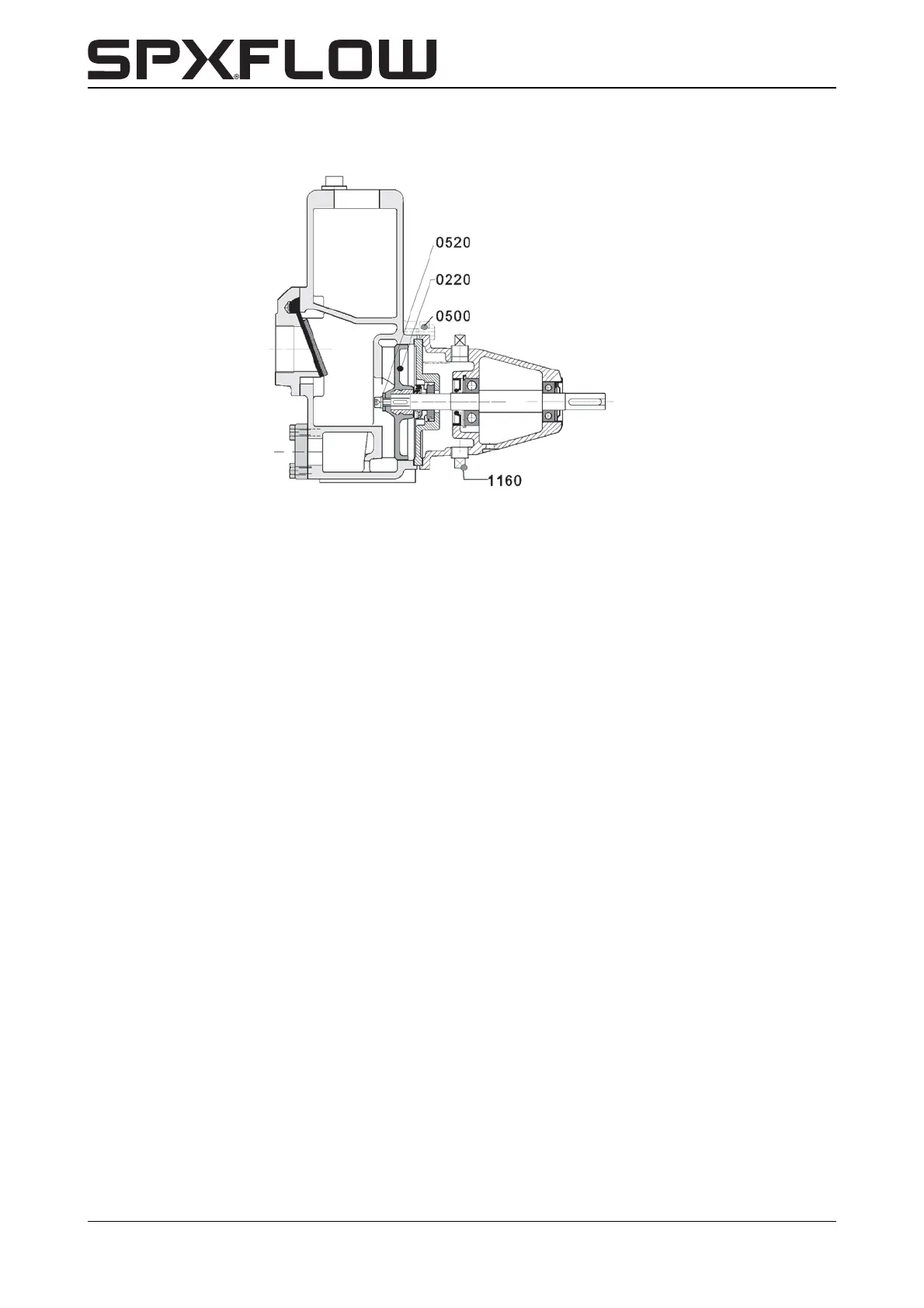

Figure 12: Disassembly impeller with bearing bracket group 0, 0+ and 00

(construction and )

Loading...

Loading...