Installation Waukesha Cherry-Burrell

Page 12 95-03087 10/2012

Fittings

When using suitable fittings, Mix Proof valves with detachable

connections can be installed in a pipe system per the fitting

requirements. The valve must be installed free of tension. After

the valve is installed in the pipe system, attach the control air

hoses and connect them to the electrical supply.

Contact WCB at 1-800-252-5200 for more information on our

wide variety of

fittings for all applications.

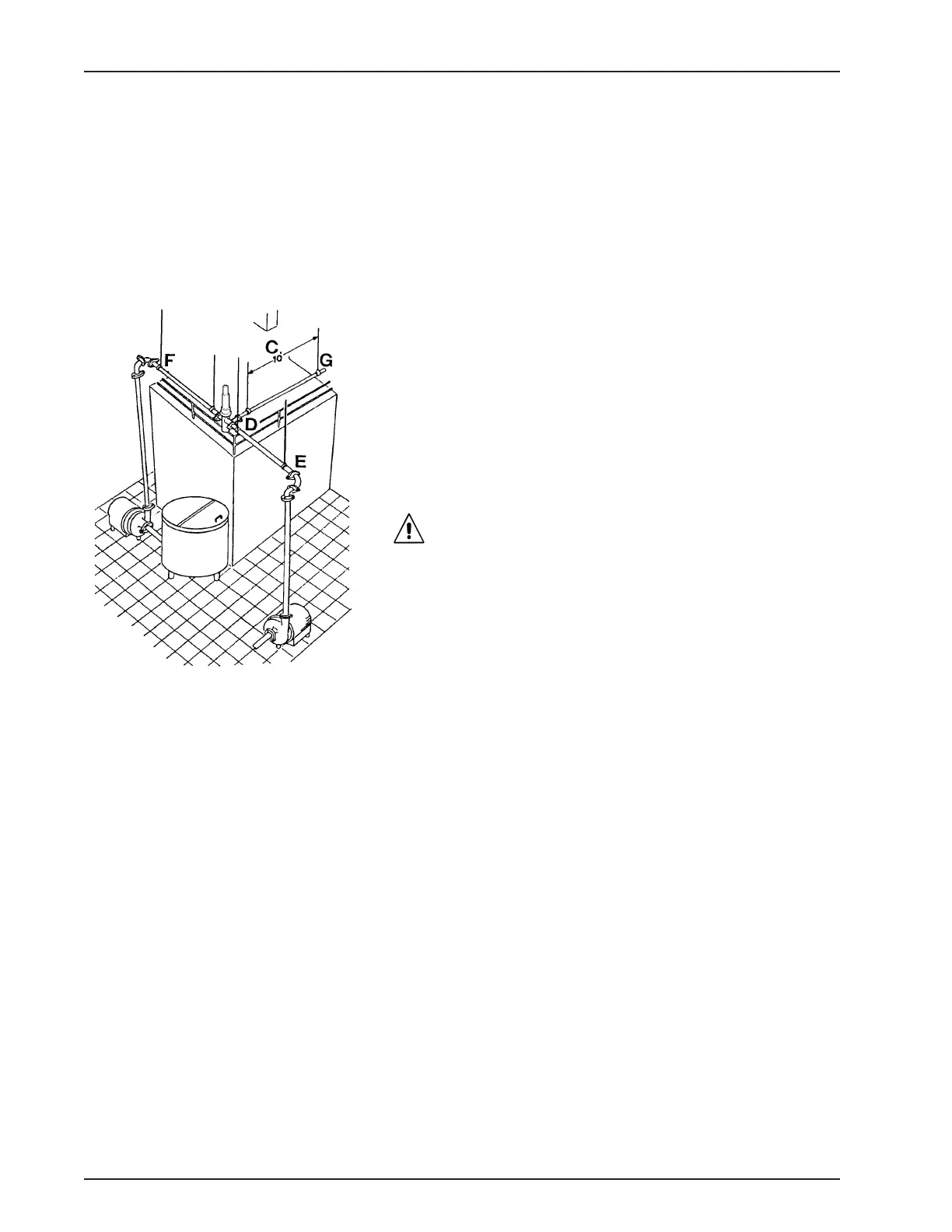

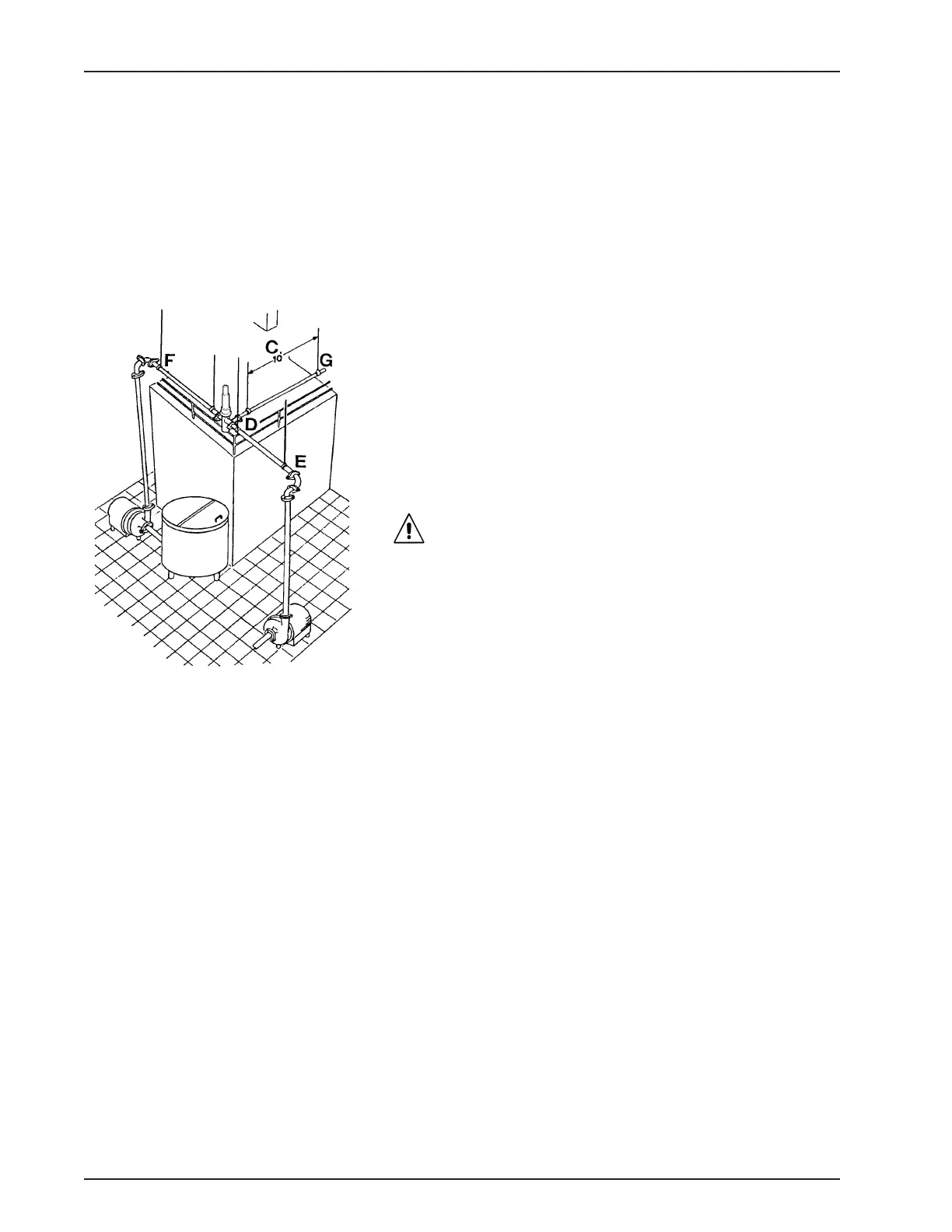

Pipeline Support

Install adequate supports to prevent strain on the fittings, valves

and equipment connections.

.

1. Install supports at least every 10 feet on straight runs of pip-

ing. (Figure 2, item C).

2. Install supports on both sides of the valves as close as possi-

ble to the connections. (Figure 2, item D).

3. Install supports at each change of pipeline direction. (Figure

2, item E and F).

4. For pipelines passing through walls, floors or ceilings, provide

at

least 1 inch (25 mm) of clearance around the pipe to allow

for expansion and contraction. (Figure 2, item G).

CAUTION:

In higher temperature applications, ensure

proper accommodation for thermal expansion in the

pipeline design to minimize stresses on the valve bodies.

Excessive mechanical and thermal stresses can distort and

damage the valve bodies.

Installing Valve Manifolds

Install automatic valve manifolds with a uniform pitch for proper

drainage. Elevate one corner of the cluster and pitch 1/16" per

foot (1.59 mm per meter) if desired. Arrange the supports for the

floor-mounted valve manifolds to provide alignment of the inlet

and outlet lines.

Installing the Valve

1. If solenoids are mounted in a control top, connect the air sup-

ply lines to “air in.” If solenoids are mounted externally from

the control top, connect the air lines as explained in “Solenoid

Valve Port Connections” on page 16.

2. Using caution, lift the actuator asse

mbly and set the actuator

in the body assembly.

3. Lower the valve slowly into the body, making sure the lower

st

em enters the lower bearing carrier.

4. Tightly clamp the yoke/body flange.

5. Connect the air lines to A, B and C, as shown in Figure 9 on

page 15

Figure 2 - Pipeline Support

Loading...

Loading...