Operation Waukesha Cherry-Burrell

Page 16 95-03087 10/2012

Operation

All functions of W-Series mix proof valves are pneumatically con-

trolled using a 75 min. to 100 max. psi (5.2 to 6.9 bar) clean air

supply.

The valve contains a large and small spring in the valve actuator.

The springs hold the valve seats in the closed position.

Large Spring

• Located in top air chamber of cylinder.

• Holds valve in the closed position.

Small Spring

• Located in the extended hub of the upper piston.

• When the valve is open, the spring acts on the upper seat

stem to hold the upper and lower plugs together.

Solenoid Valve Port

Connections

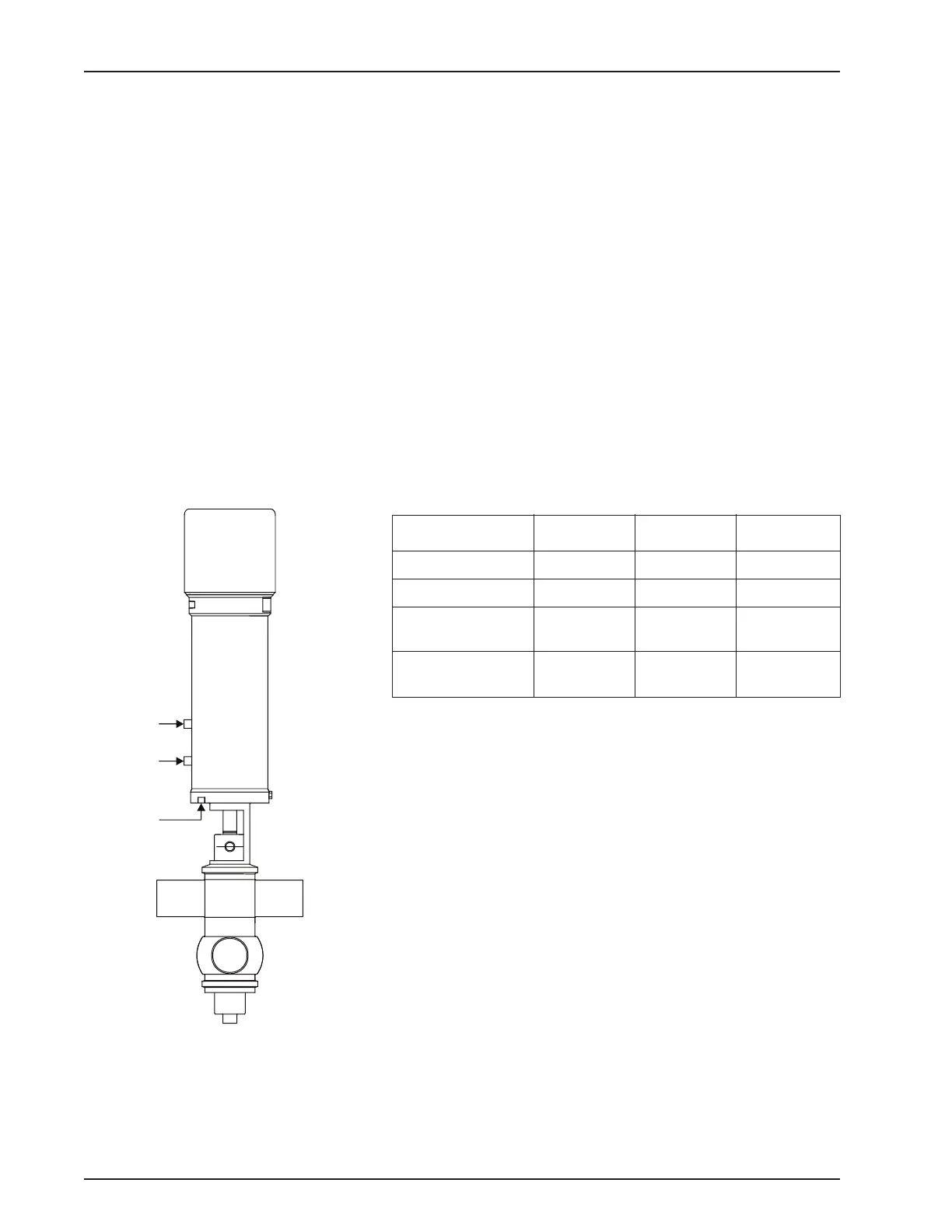

Figure 9 - Solenoid Valve Port

Connections

VA100-093E

Up to three air supplies controlled by solenoid valves supply air to

the valve actuator (Figure 9).

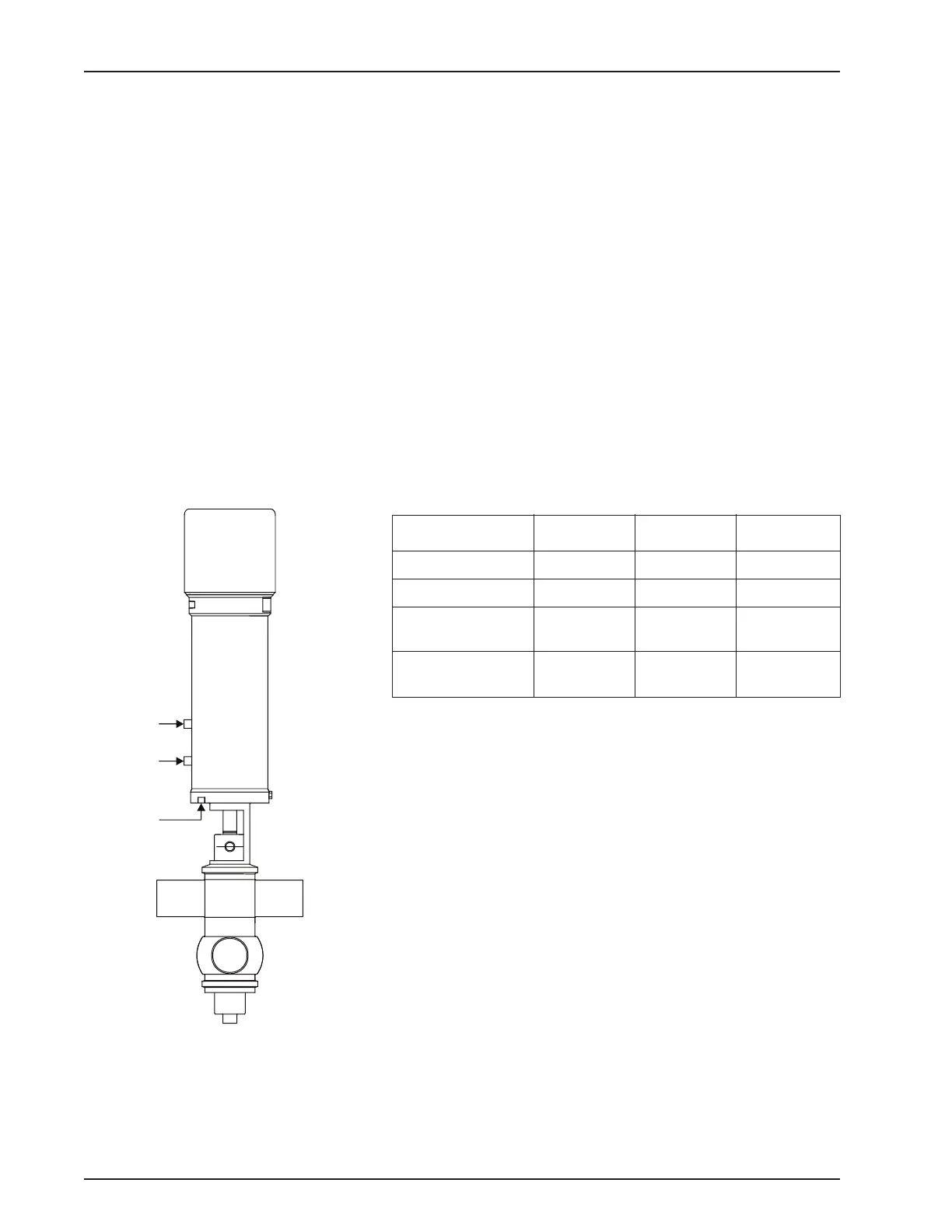

Table 3: Solenoid/Valve Position

Condition Solenoid 1 Solenoid 2 Solenoid 3

Closed OFF OFF OFF

Open ON OFF OFF

Upper Seat

Cleaning *

OFF ON OFF

Lower Seat

Cleaning *

OFF OFF ON

1 = Valve Open Inlet Solenoid

2 = Upper Seat Clean Inlet Solenoid*

3 = Lower Seat Clean Inlet Solenoid*

ON = Solenoid energized (OPEN). LED is lit.

OFF = Solenoid de-energized (CLOSED). LED is off.

Solenoids are normally closed.

Air connections are 1/8" NPT x 1/4" push-to-connect poly tube fit-

tings.

* Seat lifting is an option which requires (2) two additional air sup-

plies. Non-seat lifting valves (NSL) only have one air inlet (1).

For specific air-routing and solenoid porting, please refer to con-

trol module publications 95-03083 (2-piece) or 95-03077 (3-Piece

(obsoleted)).

Loading...

Loading...