Waukesha Cherry-Burrell Installation

10/2012 95-03087 Page 11

Installation

CAUTION: When installing the valve, ensure that no

foreign materials (e.g. tools, screws, welding wire,

lubricants, cloths, etc.) are enclosed in the system.

Location

The valve must be in a vertical position to ensure that the vent/

drain outlet system functions properly.

The vent/drain outlet at the bottom of the Mix Proof valve must

not be obstructed. The unrestricted vent/drain outlet must allow

leakages and cleaning/rinsing/sterilization fluids to go to atmo-

sphere in order to guarantee mix pr

oof safe separation. If hoses,

pipes, or other components are mounted to the vent/drain outlet

to prevent splashing of leakage and cleaning/rinsing/sterilization

fluids, then they must be designed such that the fluids flow freely

to atmosphere.

CAUTION:

Isolate products away

from the valve prior to performing

maintenance.

Locate the valve for easy access for inspection.

Ensure that the valves and pipe systems drain properly. The two-

piece body option enables the positions of the connections to be

adjusted in relation to each other.

Welding Instructions

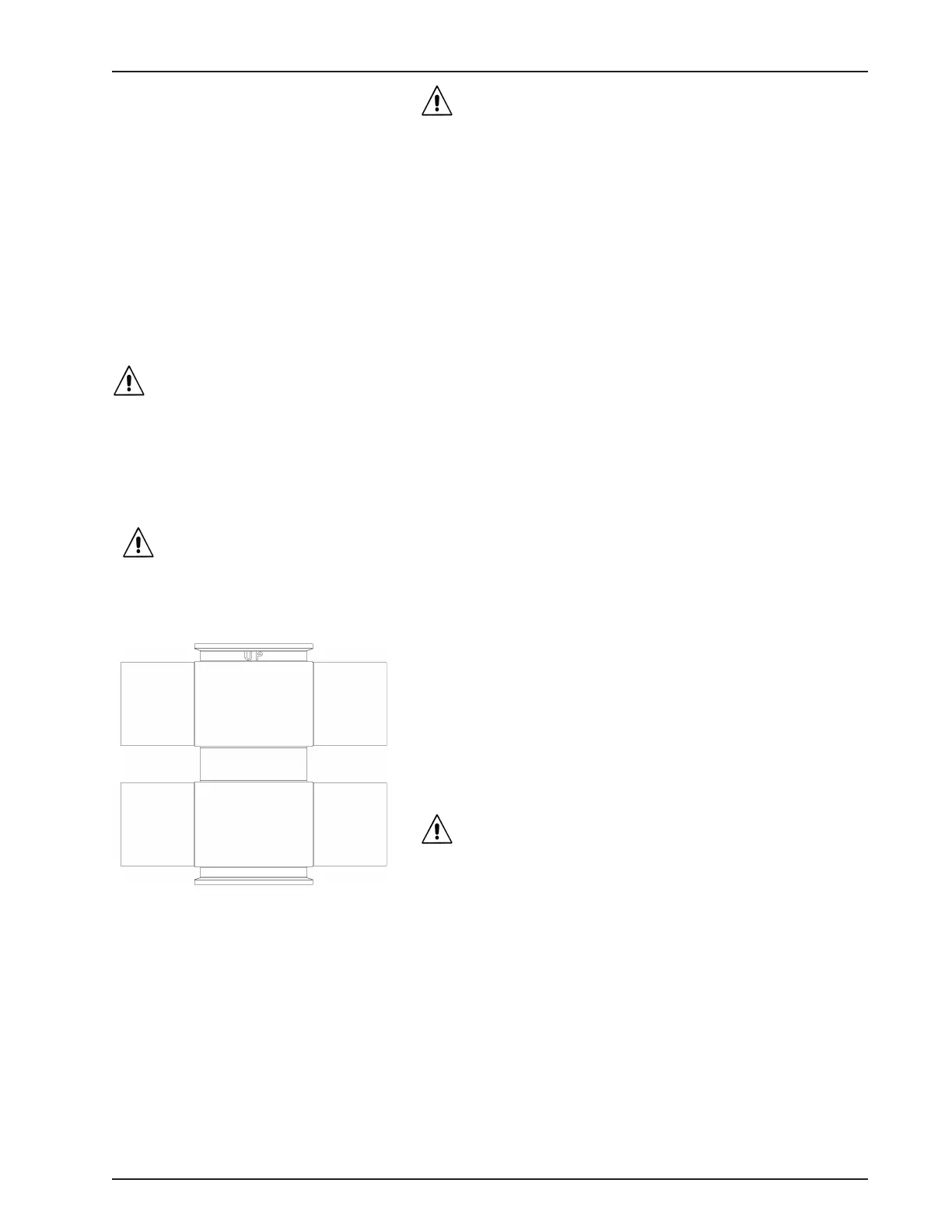

Figure 1 - Valve orientation

Prior to installing, thoroughly inspect each valve. When using but-

tweld two-piece body valves, clamp connections must be used on

either the upper or lower body to allow for servicing of the o-ring

seal between the bodies. This does not apply single-piece bod-

ies.

Mix Proof valves with welded connecti

ons require the following to

be performed before installation:

• Prior to installation, remove the stem actuator assembly and

lower bearing carrier.

• Remove all seals from the body.

• Weld the body into position, ensuring that the connection is

free of tension and distortion.

NOTE: Orient the valve so that the "UP" inscription (near the

adapter-to-body connection) is pointed toward the actuator. See

Figure 1.

CAUTION:

Welding must be carried out by qualified

personnel.

For manifold welding, fixture tables are recommended. Matrix

manifold welding requires a controlled deliberate process to

maintain the alignment of the parts.

Air Supply

Install the valves using dry, filtered air. Lubrication is not required.

If using lubricated air, refer to the solenoid manufacturer’s specifi-

cations. The air supply must be 75 to 100 psi (5.2 to 6.9 bar).

Flow Direction

The valves should be installed to close against the flow to prevent

hammering.

CAUTION: Before attempting to

buttweld an automatic valve into

a line, disassemble the body

from the actuator. Dissipate

heat away from the valve body

to prevent warping.

Loading...

Loading...