Operation Waukesha Cherry-Burrell

Page 18 95-03087 10/2012

6. Vent the air in chamber 2 (Figure 9, page 16) to deactivate

the seat lift.

7. If used, pressurize chamber 3 to activate the lower seat push.

8. Confirm that the proximity

switches conform to Table 4 on

page 17. Verify the switch status on the PLC control system.

9. Vent the air in chamber A to deactivate the seat lift.

10. Disconnect the air from the valv

e actuator. placing the valve

in the fail-safe position. Verify that the proximity switches reg-

ister that the valve is fully closed.

Corrective Action

If the double seat Mix Proof valve fails to respond as indicated

above, immediately check the valve assembly and wiring to

locate and correct the cause:

• First, check the proximity switch adjustment.

• Check for the correct assembly and adjustment of the valve.

• For specific information on switch setting, please refer to

control module publications 95-03083 (2-piece) or 95-03077

(3-Piece (obsoleted)).

Valve Operating

Conditions

See Figure 9 on page 16 for port and corresponding chambers.

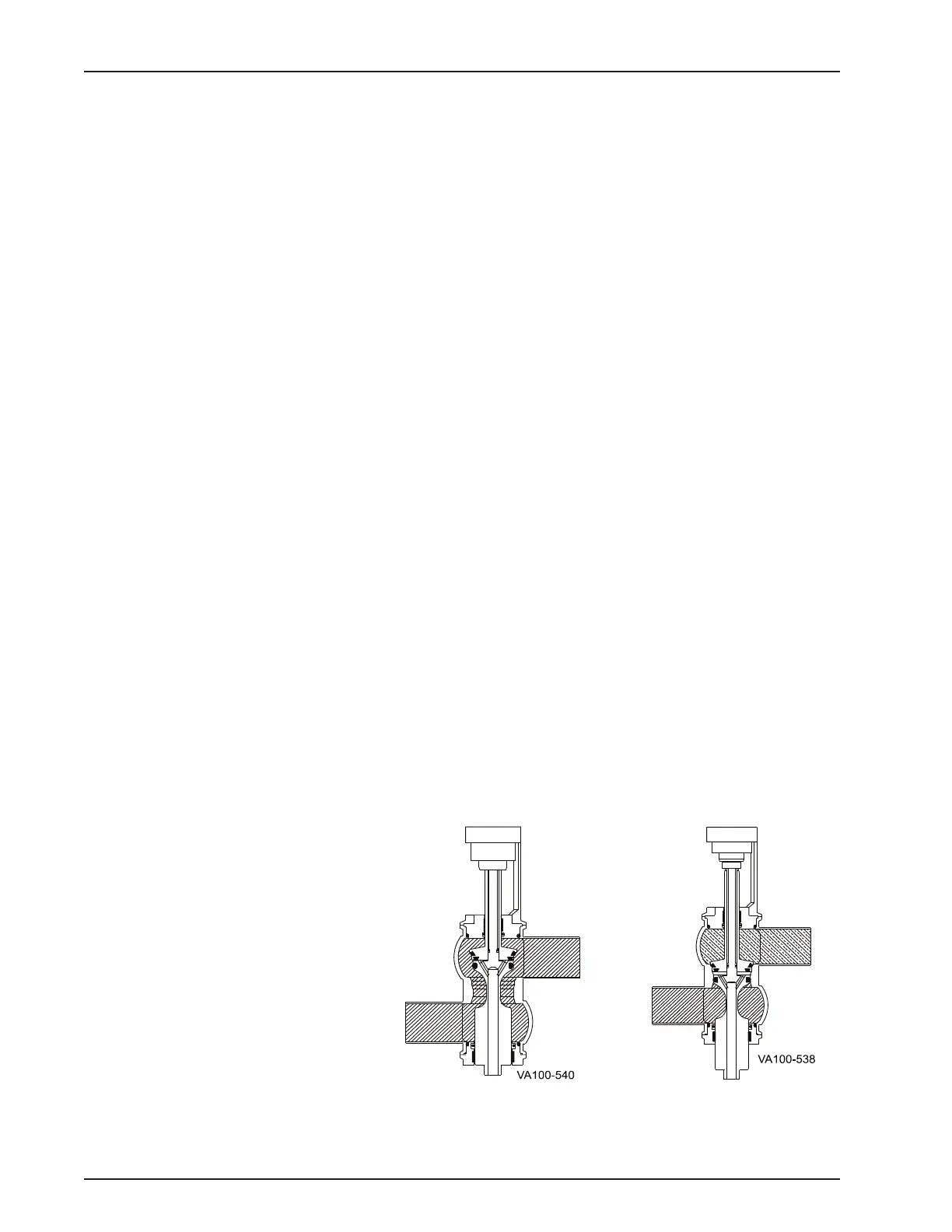

Valve Open

The valve is open when Chamber 1 is pressurized and Chambers

3 and 2 are vented. See Figure 10.

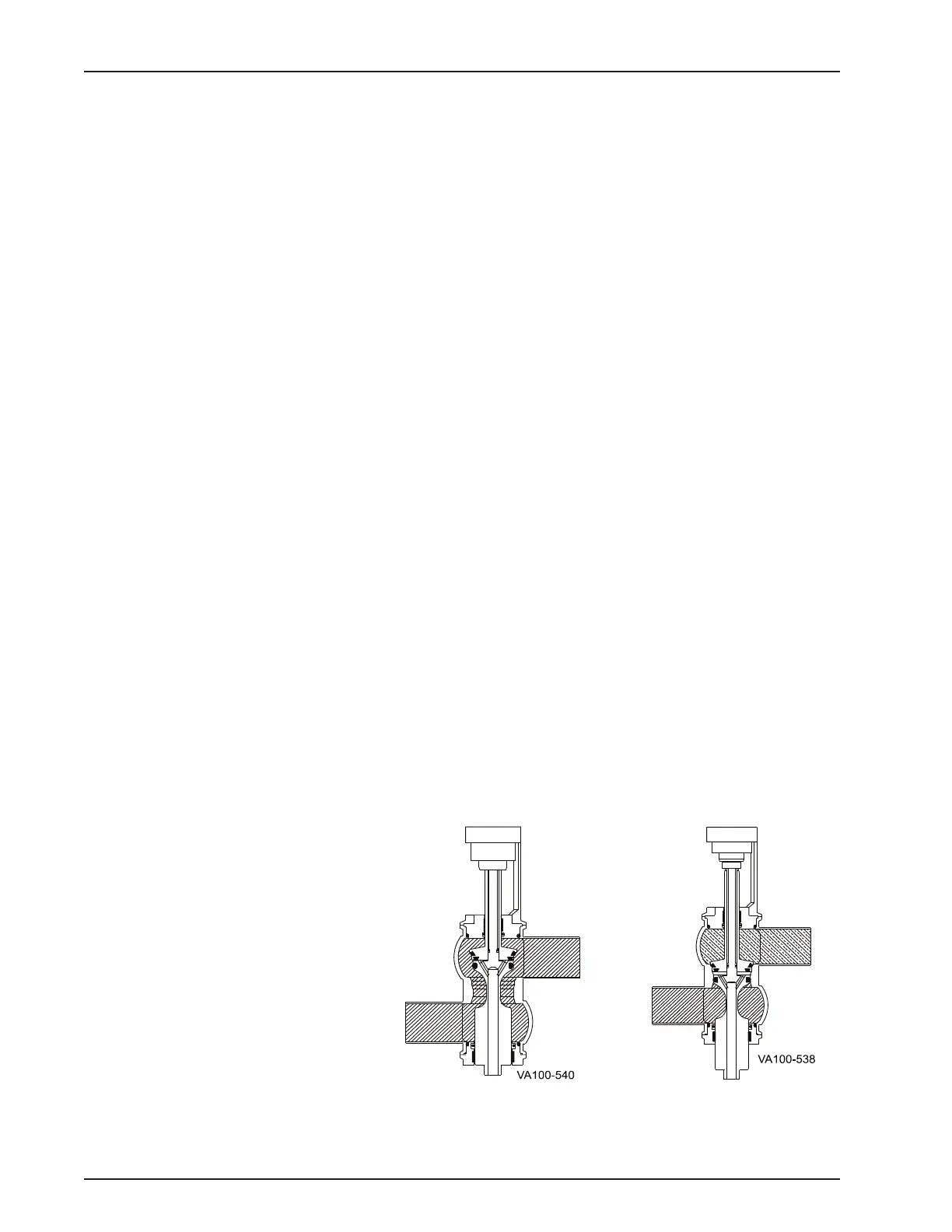

Valve Closed

The valve is closed when Chambers 3, 1, and 2 are vented. The

large spring closes the valve to the fail safe position. See Figure

11.

Figure 10 - Valve Open Figure 11 - Valve Closed

Loading...

Loading...