Waukesha Cherry-Burrell Maintenance

10/2012 95-03087 Page 31

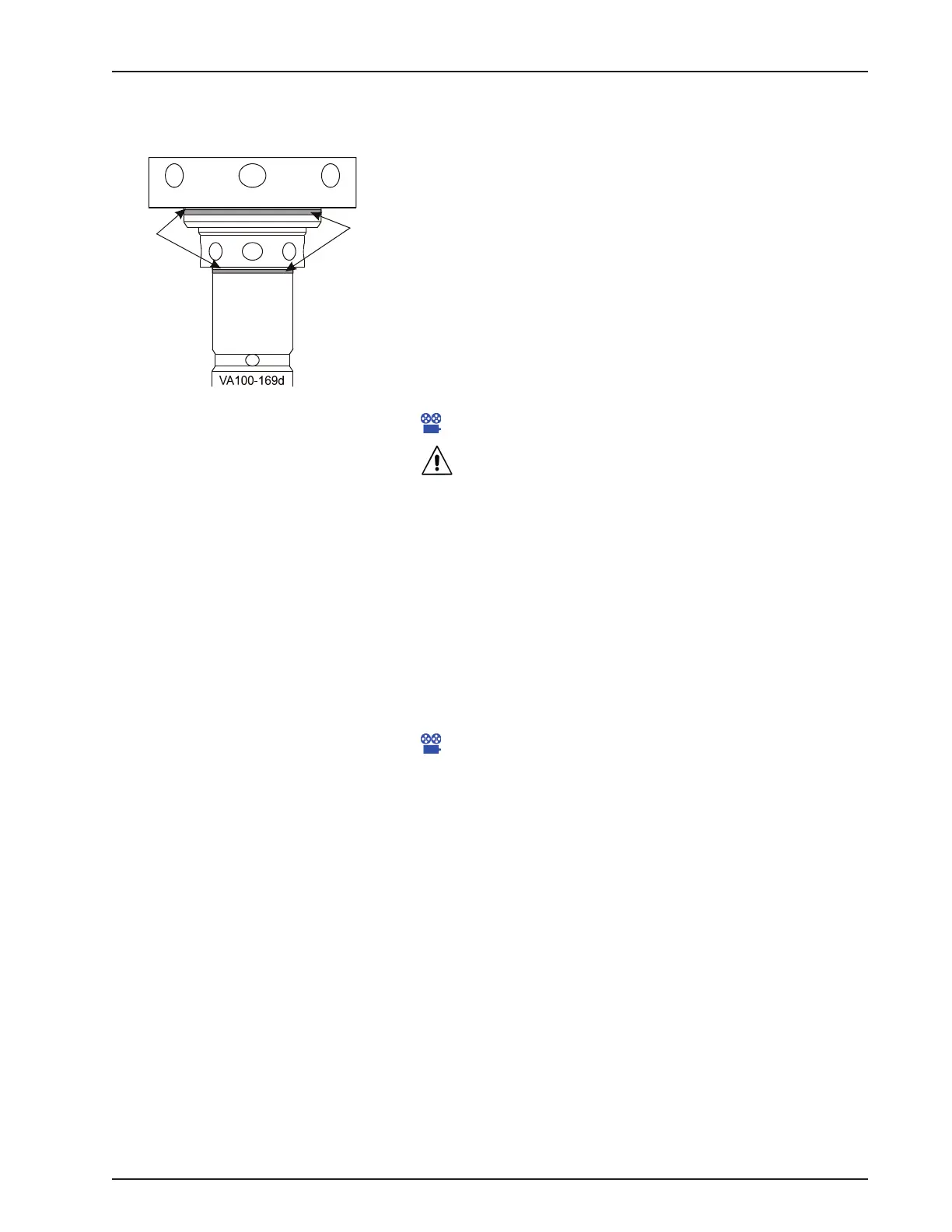

Reassembly of Valve

Stems

Figure 30 - Assembly

NOTE: Perform maintenance on stems and adapter bearings and

o-rings while the stems are removed from the actuator and before

reassembly.

Upper Stem Assembly

1. Apply Bostik® Never-Seez White Food Grade with PTFE or

equivalent to the threads of the upper stem.

2. Screw the upper stem clockwise into the actuator. Hold the

adjusting sleeve stationary with a spanner or allen wrench.

3. Screw the upper stem in until the scribe line (Figure 30, item

A) within the etch mark adjustment zone (item B) aligns with

the bottom of the adjustment sleeve. This is the factory-set

lower seat clean position. See “Seat Cleaning Adjustment” on

page 22 for instructions on modifying the seat clean move-

ment.

Maintenance Video 6: Upper stem reassembly into valve

WARNING:

Do not screw the upper stem all the way into

the actuator, as internal o-ring damage may result.

Lower Stem Assembly

1. Apply Bostik® Never-Seez White Food Grade with PTFE or

equivalent to the threads of lower stem.

2. If the valve has external flush, slide the spray bushing onto

the inner stem of the lower stem.

3. Screw the lower stem clockwise into the actuator until metal-

to-metal contact stops.

4. Using an open-end wrench and rubber hammer, rap the

lower stem to lock the threads into place within the actuator.

Maintenance Video 4: Lower stem reassembly into valve

Loading...

Loading...