Waukesha Cherry-Burrell Introduction

10/2012 95-03087 Page 9

Operating Parameters

Temperature Range:

The recommended operating temperature is determined by the

material used for the seals.

No special precautions are required for applications within a tem-

perature range of 32°F to 180°F (0°C to 82°C).

For applications above 190°F (88°C), clearances can be affected

by excessive thermal expansion when the valve is installed in

compact fabrications or manifolds. Valve bodies have thicker

cross-sections than tubing, but thermal expansion can affect

clearances in interconnecting piping sections.

If operating below 32°F (0°C):

• Control air must have an appropriately low dew point.

• Valve stems must be protected from icing to ensure long

work

ing life for valve stem seals.

Solenoid valves may not be used in the control module in room

environments below 32°F (0°C) and over 140°F (60°C), as func-

tion cannot be guaranteed.

Seal Compatibility

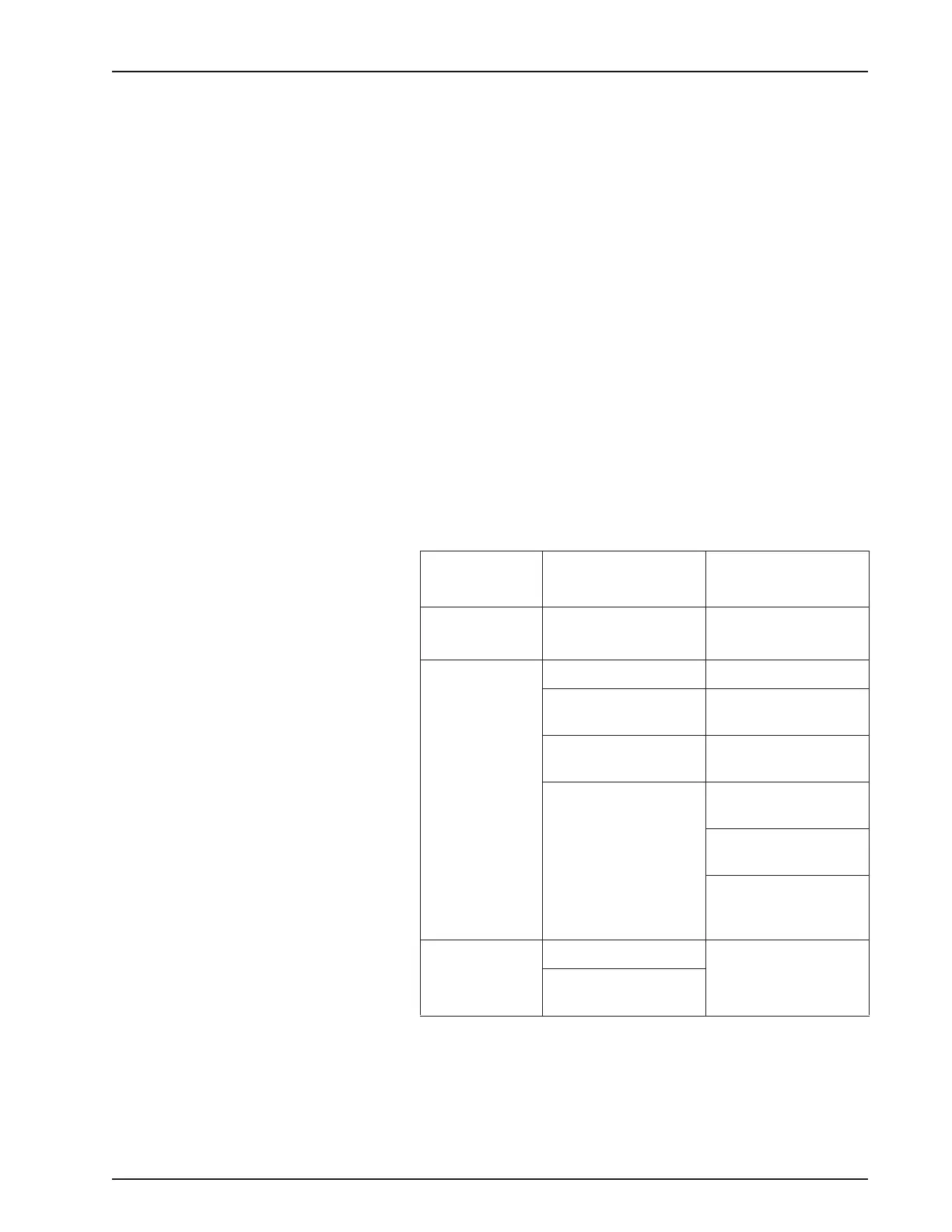

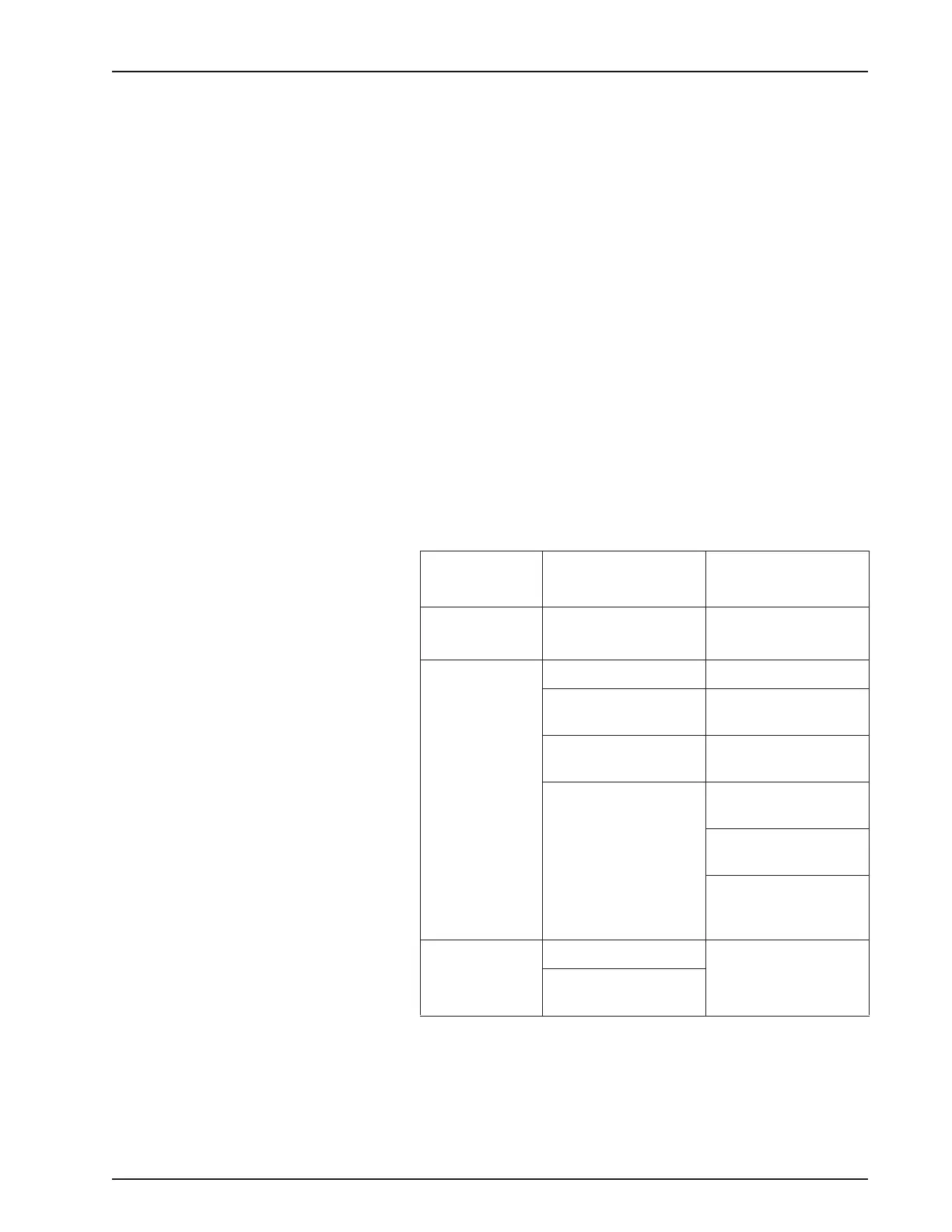

Table 1: Seal Compatibility for FKM/EPDM Seals

Fluorelastomer

(FKM) Seals

EPDM Seals

Thermal Range

of Application

32°F to 375°F

(0°C to 190°C)

0°F to 275°F

(-18°C to 135°C)

Chemical

Resistance

Silicone oil and grease Silicone oil and grease

Ozone, aging and

weather resistant

Ozone, aging and

weather resistant

Oils and fats Hot water and steam

u

p to 275°F (135°C)

Aliphatic, chlorinated

an

d aromatic

hydrocarbons

Many organic and

inorganic acids

Cleaning agents, soda

a

nd potassium alkalis

Many polar solvents

(a

lcohols, ketones,

esters)

Not compatible

with

Superheated steam Mineral oil products

(oils, greases and

fuels)

Formic and acetic

acids

Contact WCB Application Engineering for other fluid

compatibility.

FKM and EPDM seals comply with FDA regulations.

Loading...

Loading...