Waukesha Cherry-Burrell Operation

10/2012 95-03087 Page 17

Automatic Fail-Safe

System

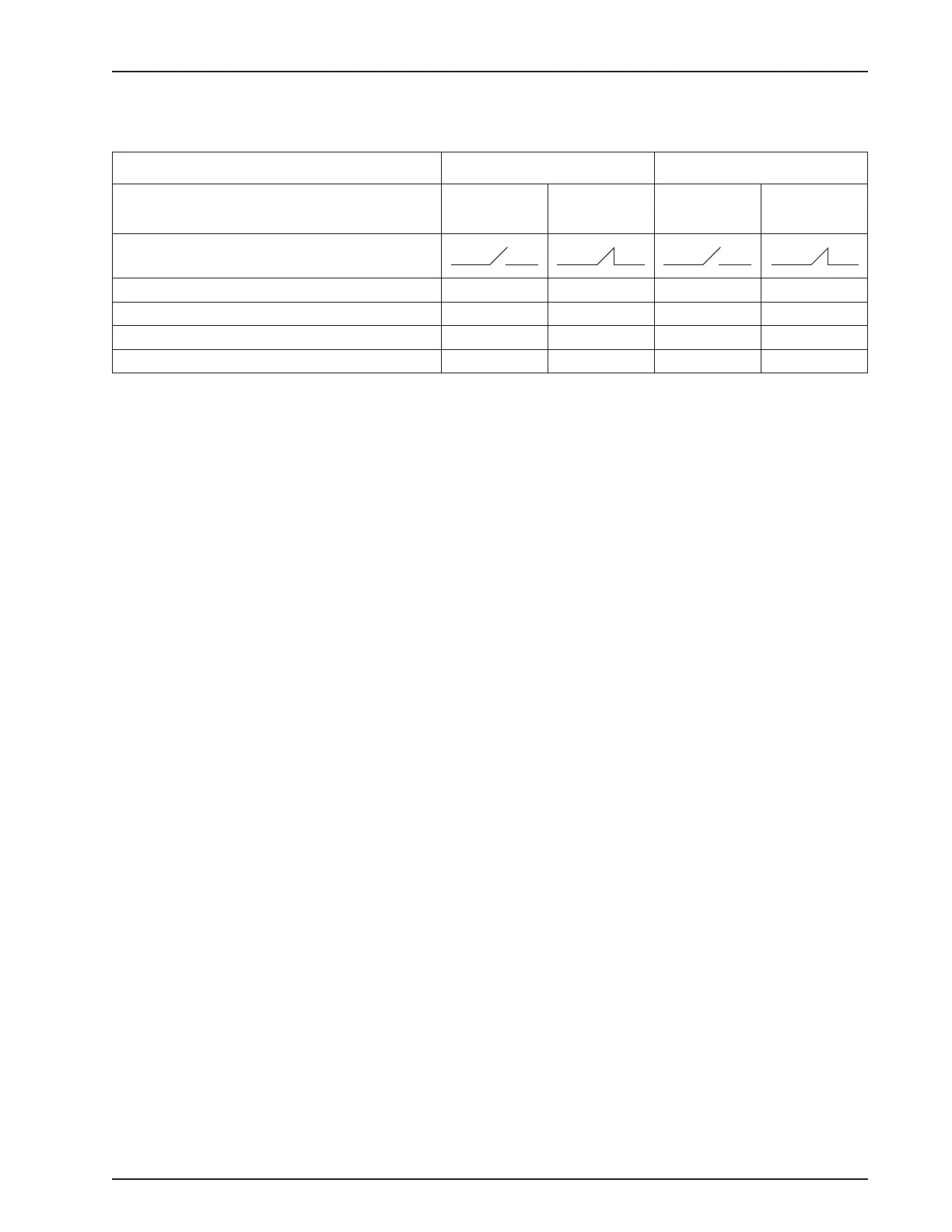

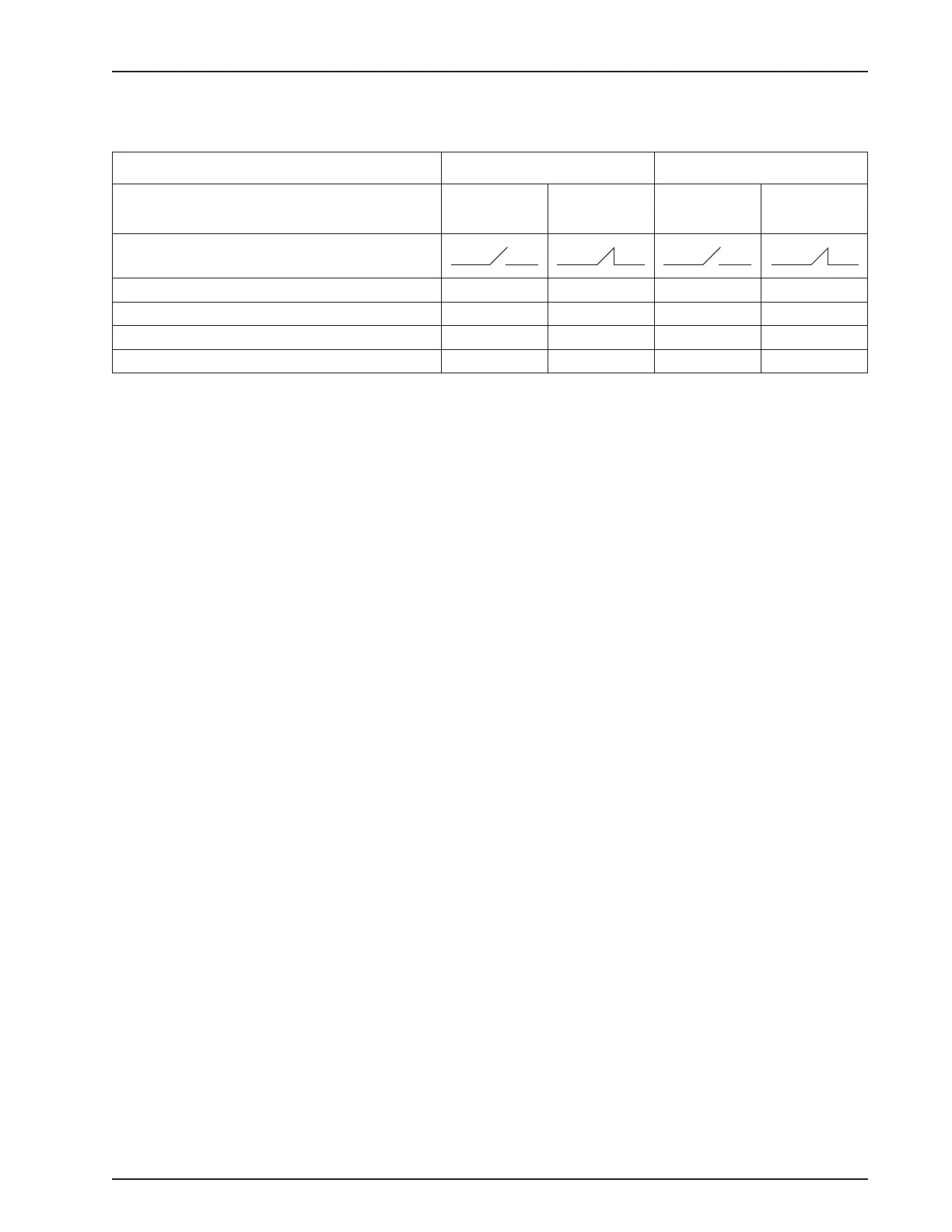

Table 4: Valve Stem Detection Conditions

W71/W73 W72RS/W72RSP

Condition

Upper

Sw

itch (NO)

Lower

Switch (NC)

Upper

Switch (NO)

Lower

Switch (NC)

Switch Symbol

Valve Closed 0 1 0 1

Valve Open 1 0 1 0

Valve Closed with Upper Seat Clean * 0 1 0 0

Valve Closed with Lower Seat Clean * 0 0 0 1

Notes:

1 = Energized, LED is lit; 0 = De-energized, LED is off

Upper Switch: Sends an input signal when the valve is properly

open.

Lower Switch: Sends an input signal when the valve is properly

closed.

Additional Switch: A third yoke-mounted proximity switch is avail-

able for additional signal feedback.

* W71/W73 Valves: Seat lift during both upper and lower seat

clean; indicator stem raises;

W72RS/W72RSP Valves: Seat lift during upper seat clean; seat

push during lower seat clean, indicator stem lowers.

Test Procedures

Positive Fail-Safe Detection Test

Perform a test to verify the fully closed fail-safe position. The

valve plug feedback proximity switches should be set for the fully

opened and fully closed positions of the valve. See Figure 9 on

page 16 for port and corresponding chambers.

Decommission the system, drain the lines and lock out the

pu

mps.

1. With the valve fully closed, confirm that the proximity

switches conform to Table 4. Verify the switch status on the

PLC control system.

2. Pressurize chamber 1 to open the valve (Figure 9, page 16).

Confirm that the proximity switches conform to Table 4. Verify

the switch status on the PLC control system.

3. Vent chamber 1 to close the valve.

4. If used, activate the upper seat lift either through the control

system o

r by supplying air to port 2.

5. When the upper seat lifts, confirm that the proximity switches

conform to the values in Table 4. If the yoke area does not

have a limit switch, visually confirm the upper seat lifting.

Loading...

Loading...