Waukesha Cherry-Burrell Maintenance

10/2012 95-03087 Page 29

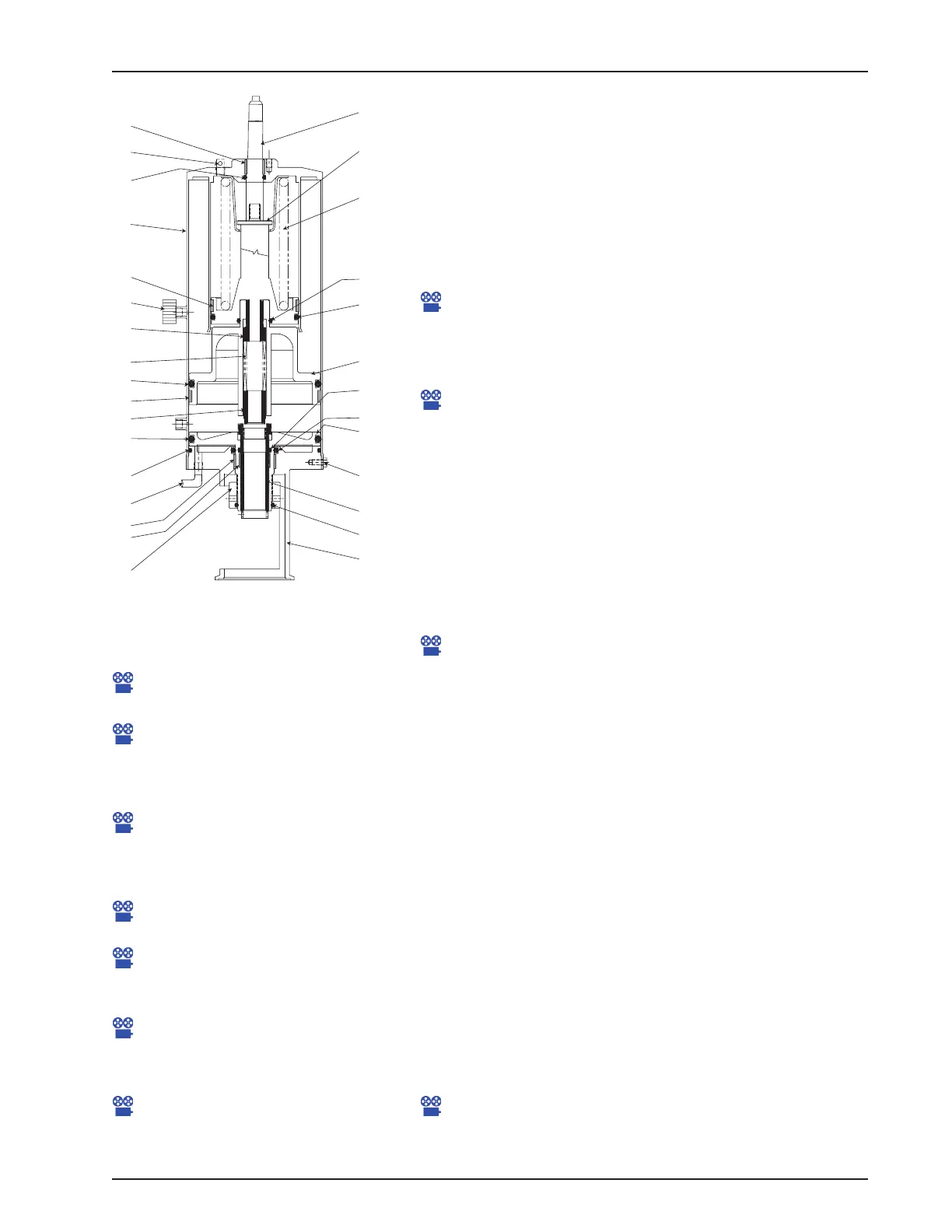

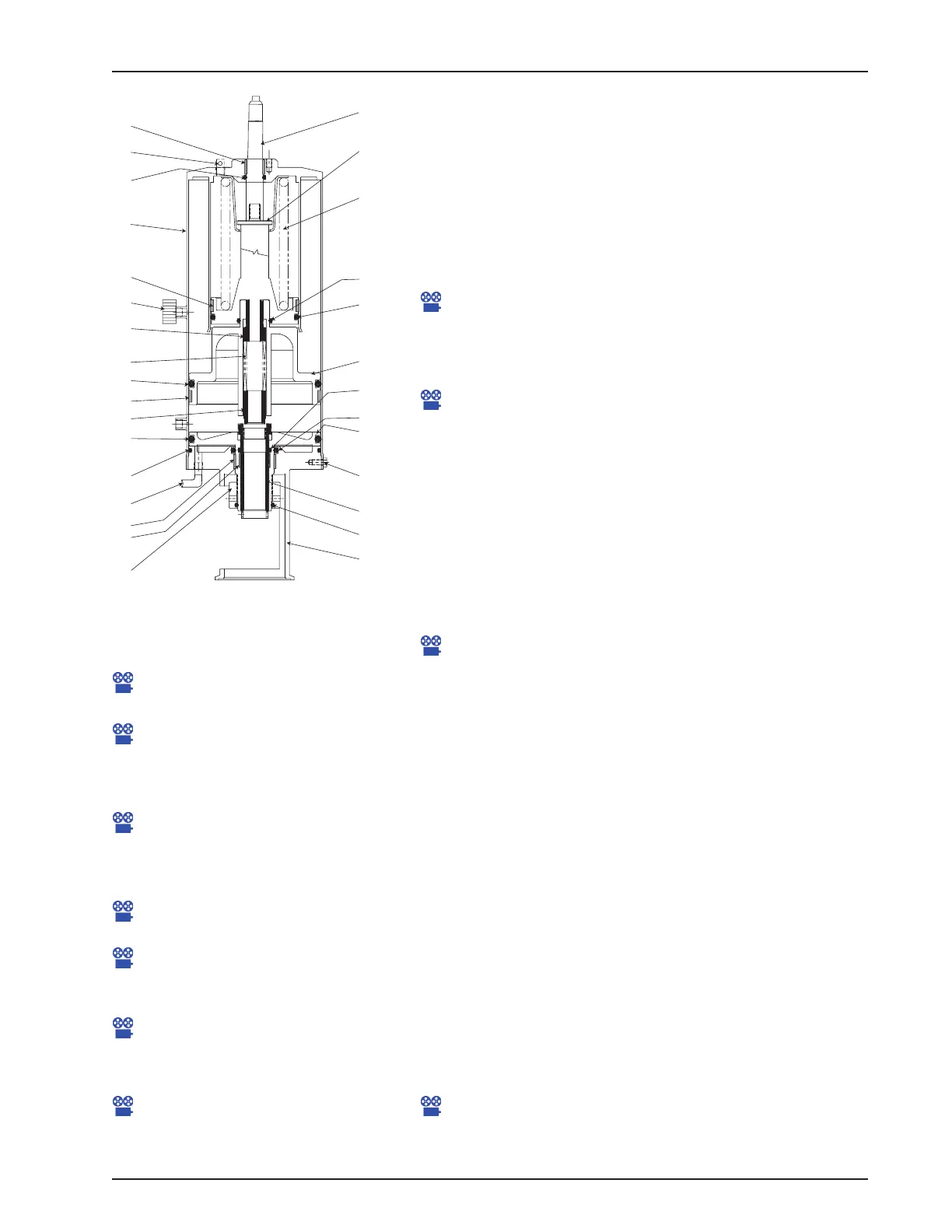

Removal of O-rings and Bearings, Seat Lifting

Actuators

NOTE: For larger drawings and complete partlists, see “W71/

W73 Seat Lift Actuator” on page 78 and “W72RS/W72RSP Seat

Lift Actuator” on page 82.

1. For seat lifting valves, remove the cap screws (Figure 27,

item 9) and remove the lower cartridge (yoke, item 12; adjust-

ing nut, item 20; adjusting sleeve, item 24; and upper seat

piston, item 23).

Maintenance Video 14: Actuator disassembly; lower

cartridge removal

2. To disassemble the cartridge, remove the adjusting nut (item

20) and separate the parts.

Maintenance Video 15: Adjusting Nut removal

3. Remove the small spring (Figure 27, item 18). On W71/W73

valves, also remove the bushing (Figure 26, item 28).

4. Pull out the upper cartridge (main piston, item 22; lower seat

spring and piston, item 10), by carefully threading in the lower

stem to pull it. Do not bend the lower stem.

Alternate method: Flip the canister

right-side up and gently

tap it on the table (or push down the indicator stem) until the

air vacuum releases and the upper cartridge slides out the

open end.

Maintenance Video 17: Main piston o-ring removal

Maintenance Video 18: Main piston

o-ring replacement with bearing

5. Inspect the nine o-rings (Figure 27, items 6, 7, 8, and 11) and

replace them if they are worn or damaged.

Maintenance Video 19: Can top

bearing and o-ring; removal and

replacement

6. Inspect the five bearings on W71/W73 (Figure 27, items 5,

14, 15, 16, and 21) or four bearings on W72RS actuators

(items 5, 14, 15, and 16). If the bearing does not extend

slightly above the edge of the metal surface, replace it.

Maintenance Video 20: Main piston

bearing

7. The bearing is split to allow its removal from the groove.

Place a screwdriver behind the bearing and pry it away from

the wall of the yoke. A needle-nose pliers can be used to grip

the bearing for removal.

Maintenance Video 21: Lower seat

lift piston reassembly

NOTE: The bearing will be damaged during removal and must be

replaced with a new bearing.

Maintenance Video 23: Reassembly

of actuator: spacers and inner

spring

8. For seat lifting valves, assemble the stack components as

shown. Make sure that the upper cartridge components are

fully inserted. Install the yoke and adjustment nut.

Maintenance Video 24: Reassembly

of lower cartridge o-rings and

bearings

NOTE: Installation of the piston and spring assembly on 4"

actuators requires a special sleeve to contain the bearing on the

piston while installing the assembly. See Figure 29 and Figure 28

on page 30.

Maintenance Video 25: Re-

installation of lower cartridge

Maintenance Video 22: Using insertion sleeve for W71/W73

Actuators

Figure 27 - W71/W73 Actuator Assembly

(Seat Lift Valve)

5

4

21

8

8

7

12

26

9

23

17

11

22

10

25

29

6

31

24

Loading...

Loading...