46

EN

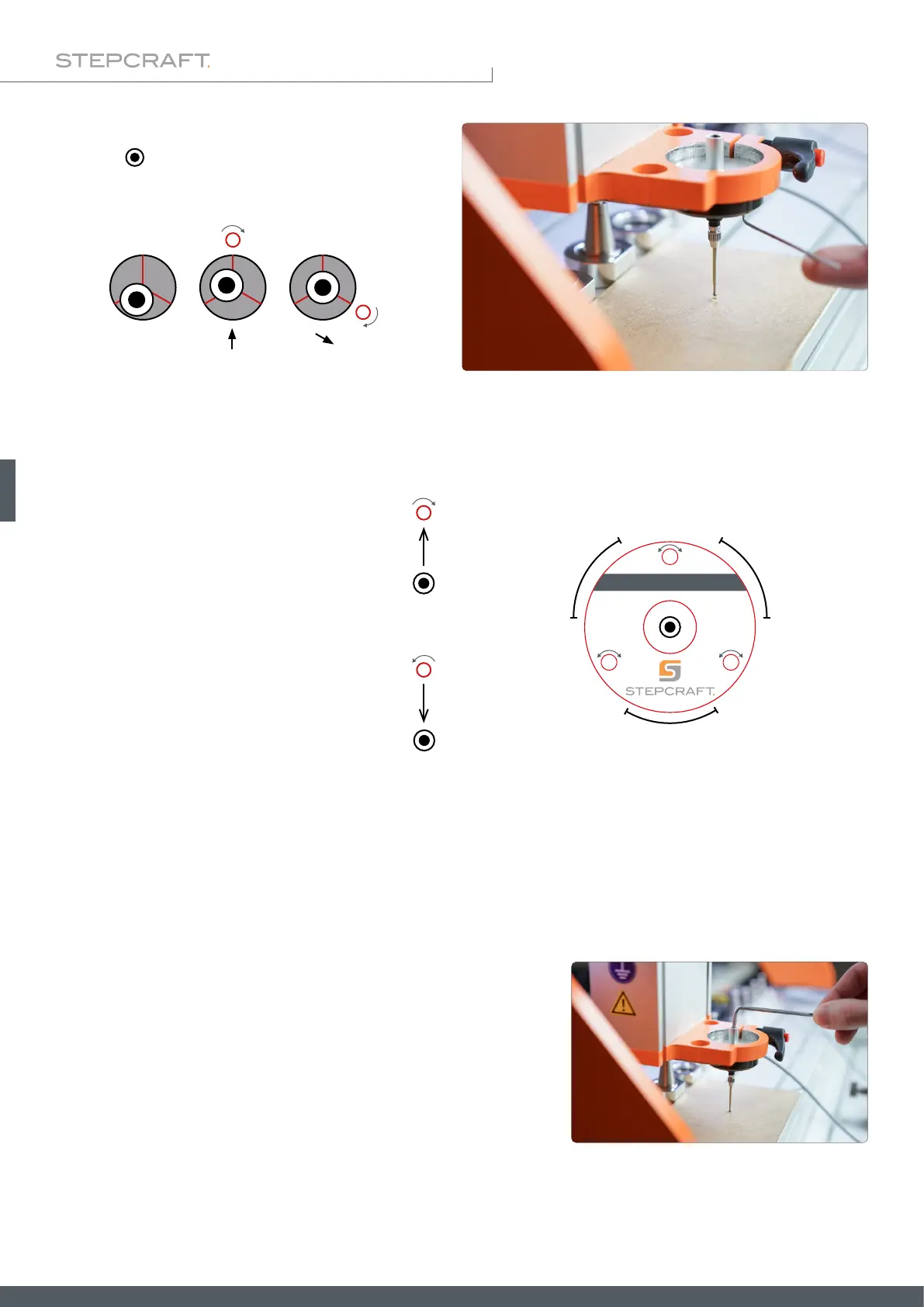

If you notice a deviation between the centers of the

probe tip ( ) and the scratch mark, move the 3D probe

up 2 mm. Use a 1.5 mm hex wrench to carefully turn

the calibration screws to counteract the deviation.

Try to only perform small changes. In between, move to the Z workpiece zero point and reassess the position of the probe

tip. Repeat this process until the probe tip is exactly centered.

Turning a calibration screw clockwise

moves the probe tip toward the calibra-

tion screw.

Turning a calibration screw counter clock-

wise moves the probe tip away from the

calibration screw.

Move one screw at a time to center the probe tip.

After the probe tip is centered, you should rotate the entire 3D probe clockwise, e. g. 90°, and check that the tip remains

centered. Repeat all steps until the probe tip is centered satisfactorily from every angle. This process takes its time, but

results in reliable measurements being obtained. Keep in mind that this procedure may be required again if you change

the method of clamping. The centering is only reliable as long as the operating conditions remain the same. For example,

if you change the xture or machine, you should check that the alignment of the 3D probe is still correct.

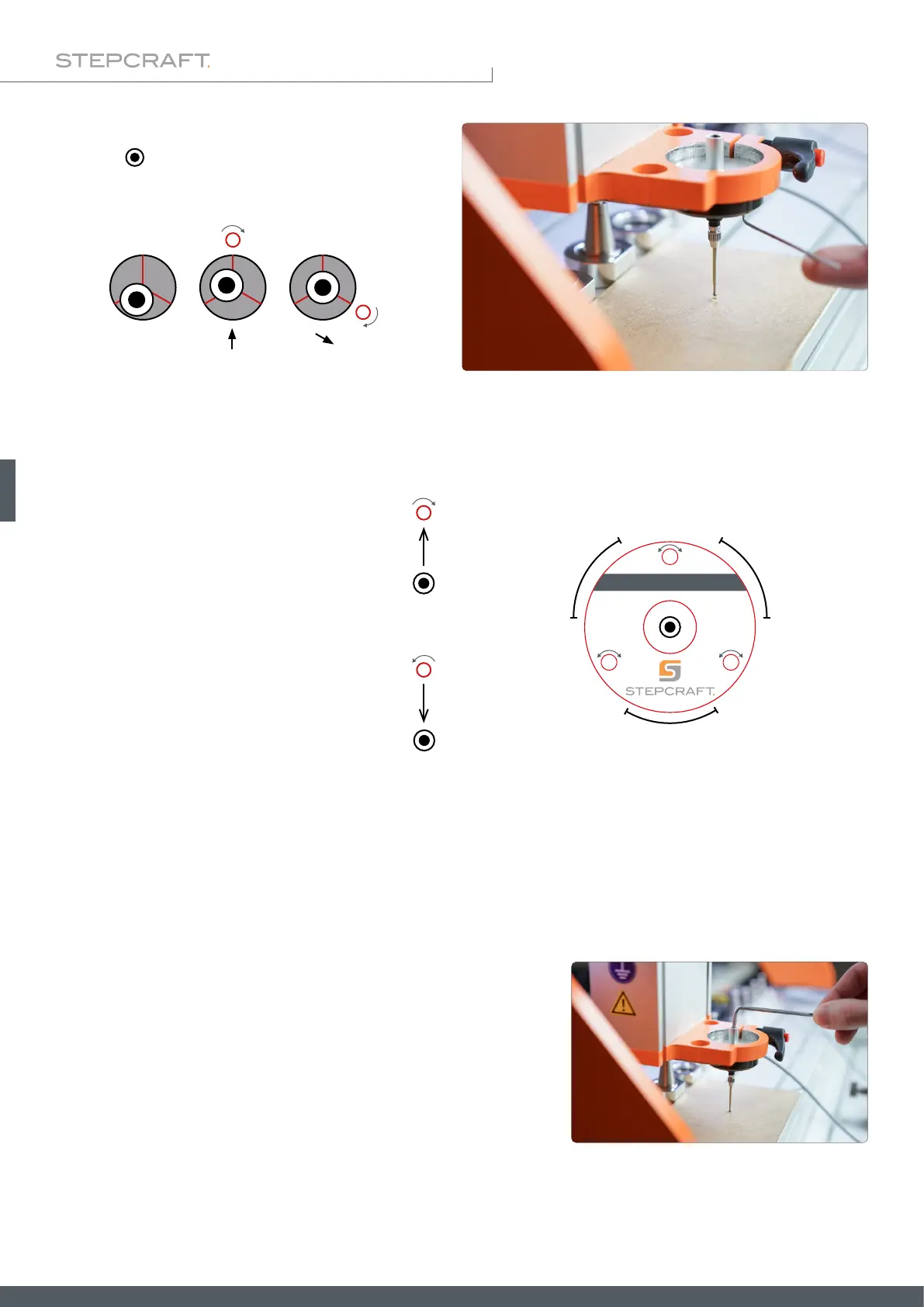

The sensitivity of the return spring can be adjusted with the preload

adjuster. The screw can be adjusted with a 3 mm hex key. When prob-

ing soft materials, you should set the sensitivity quite high. Otherwise,

there is a possibility that the probe tip will deform the material before it

actually triggers.

set 0 set 0

set 0

1

2

0

°

1

2

0

°

1

2

0

°

3D-Touch Probe

Loading...

Loading...