47

EN

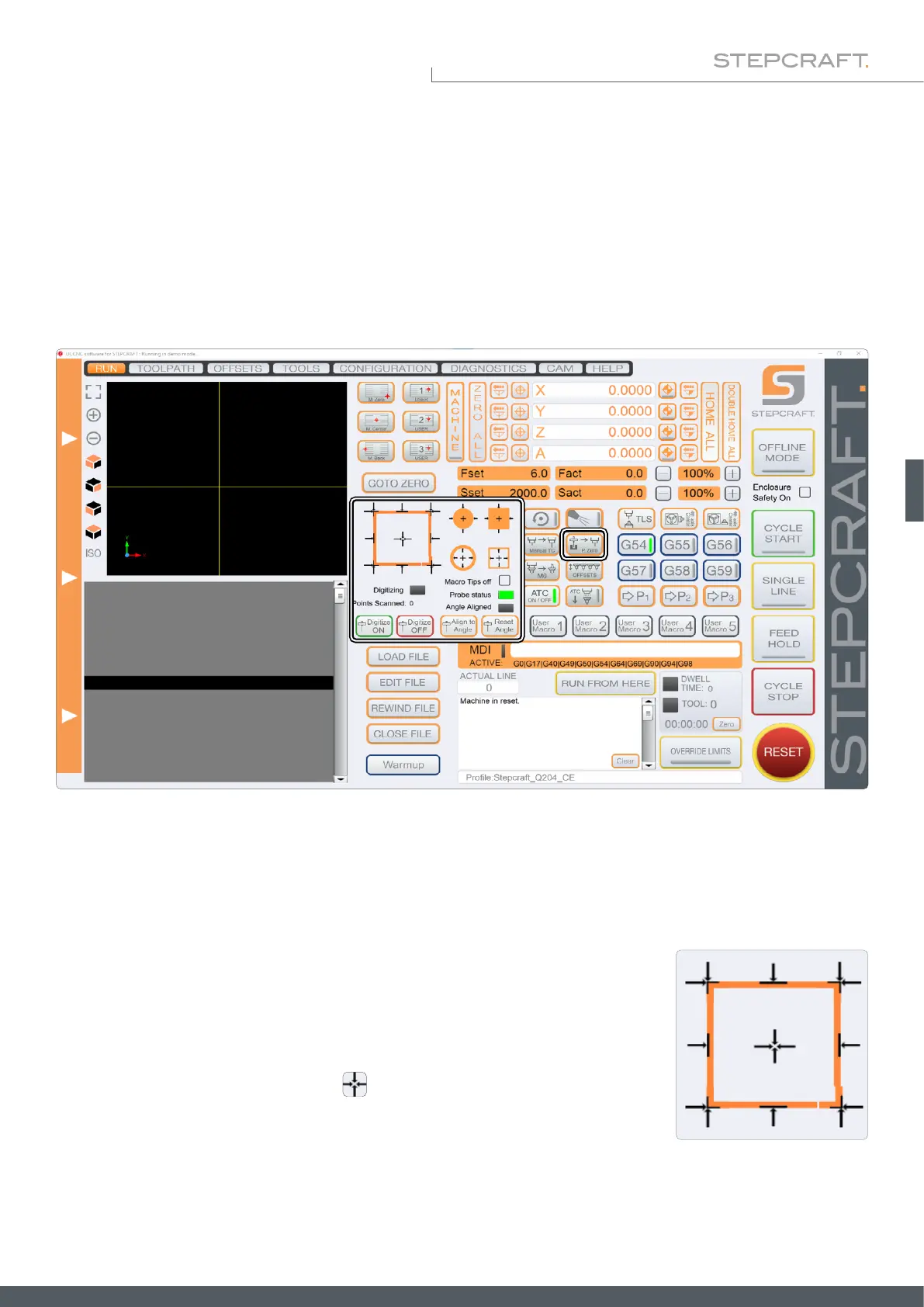

The user interface of UCCNC (depending on the used version) offers various buttons for functions using the 3D probe.

Numerous macros (previously dened workows) are integrated in UCCNC for this purpose. For example, coordinates of

edges, corners and center points can be determined automatically. You can adapt the internal coordinate system to slant-

ed workpiece edges and determine zero points that are inaccessible to end mills. You can automatically compensate an

uneven surface, which then translates into your nc-program. Furthermore, point clouds can be created in ne resolution

in order to "scan" three-dimensional objects and use them as models on the computer with third-party software.

6 Operation with UCCNC

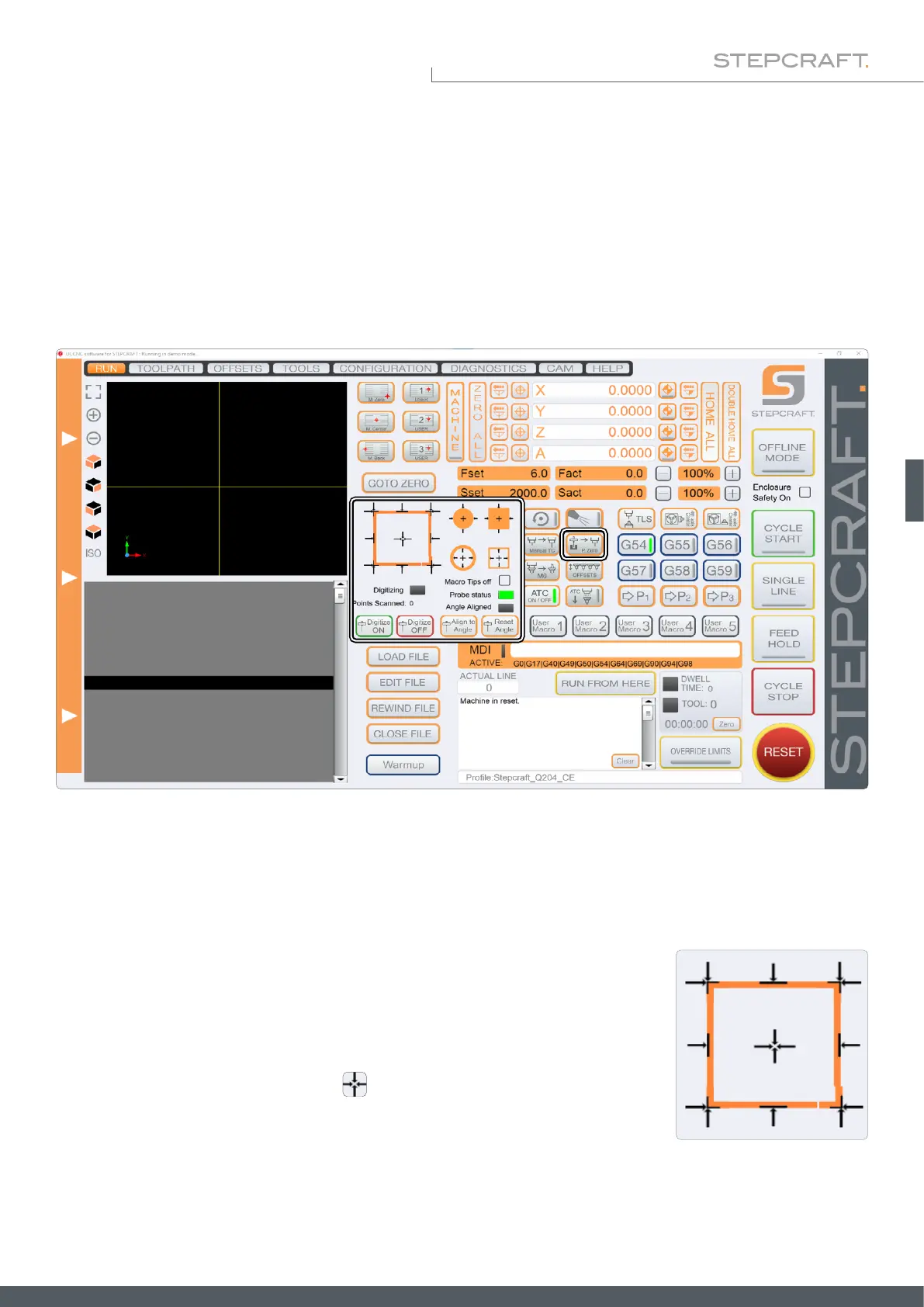

The machine moves in the direction shown until the touch probe meets the edge.

Click one of the arrows to trigger a measurement. The representation of the black

arrow shows how the probe will move. The probe must be positioned accordingly

before triggering the measurement.

You can determine the Z-zero point with . The Z-axis is moved downwards

until the 3D probe is triggered by the surface area. The Z-value will be displayed.

6.1 Automatically Probing Contours

The touch probe can be used to automatically determine edges and corners of workpieces in various ways. The various

functions are shown below. Use these functions before using Align Angle as described in „6.4 Rotation of the Coordinate

System (Align to Angle)“.

Loading...

Loading...