41

EN

2.2 Intended Scope of Use

The STEPCRAFT milling motors has been developed for private users. It is unintended for large-scale production and in-

tegration into assembly lines. It is generally designed for the usage with a CNC router but the milling motor is specically

designed for installation and connection to the STEPCRAFT machines from the D- / M- / and Q-Series. This product can

be used with third party CNC systems, although STEPCRAFT does not offer support for this use case.

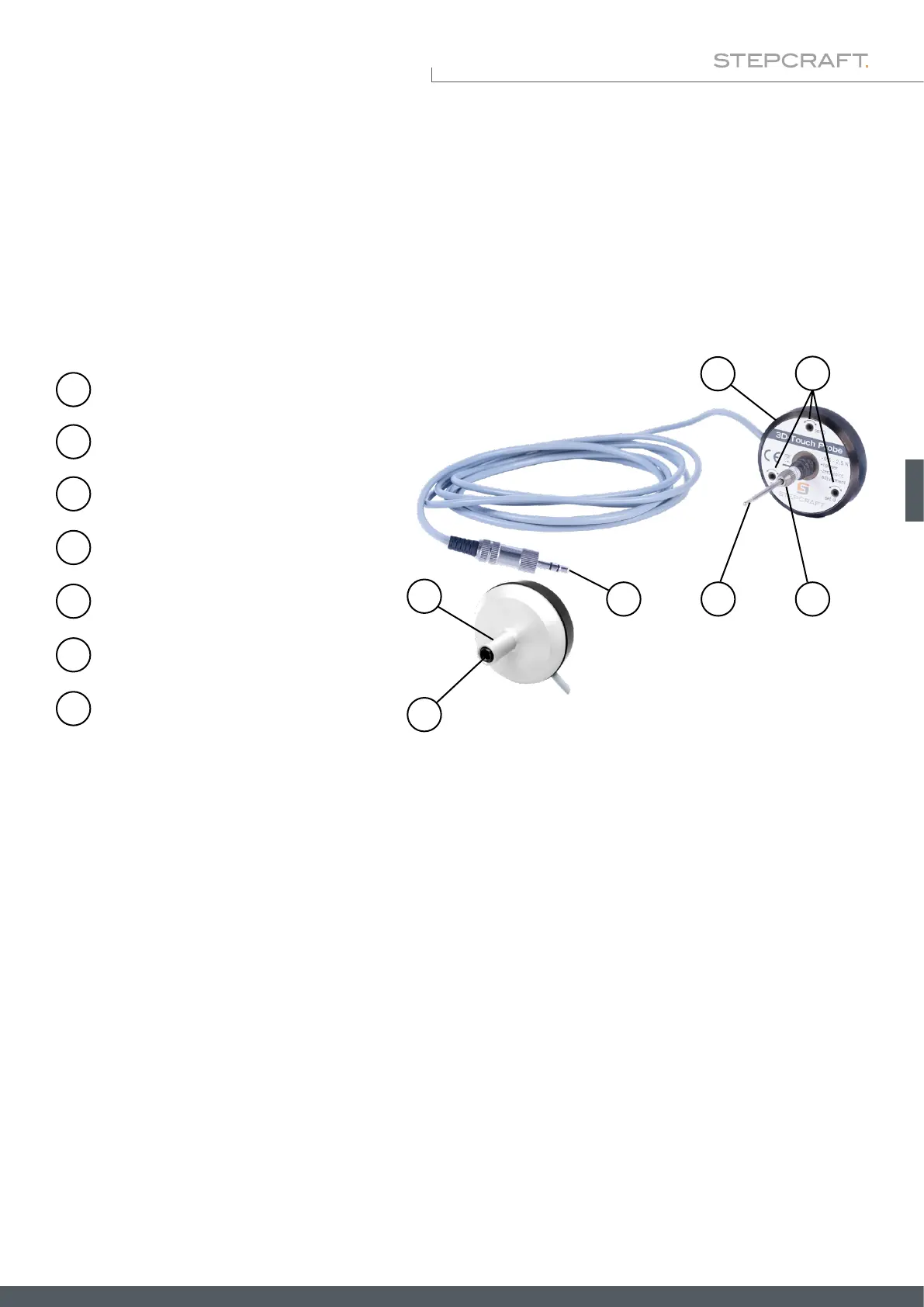

3 Drawing

1

2

3

4

5

6

7

Housing 43 mm

3,5 mm jack plug

X- / Y- / Z- calibration screws

Collet for touch probe tip

Touch probe tip

Preload adjuster

Fastening spigot 8 mm

4 Setup of the 3D Touch Probe

4.1 Environmental Conditions

General safety warnings regarding the workspace are to be found in chapter„1.2 General Safety Warnings“. The product

is solely suitable for the operation in dry, interior spaces. Protect the product against wetness and humidity. The humidity

should be within normal limits for humidity indoors (40 to 60% rH). The ideal environmental temperature for the system

is between 15°C to 25°C, respectively between 59°F and 77°F. Particularly protect the electronics against overheating

by avoiding the exposure of the milling motor to direct sun radiation or indirect heating up nearby a radiator. Keep the

environment of the machine dust-free.

4.2 Assembly and Connection of the 3D Touch Probe

The 3D touch probe can be connected to the machine control using multiple methods. The scope of delivery includes a

jack plug, which can be connected to a milling machine's jack socket. A machine from the STEPCRAFT D-Series (2nd

generation) allows you to hardwire the cable of the 3D touch probe to the machine control.

345

2

1

7

6

Loading...

Loading...