4-4

764333-675

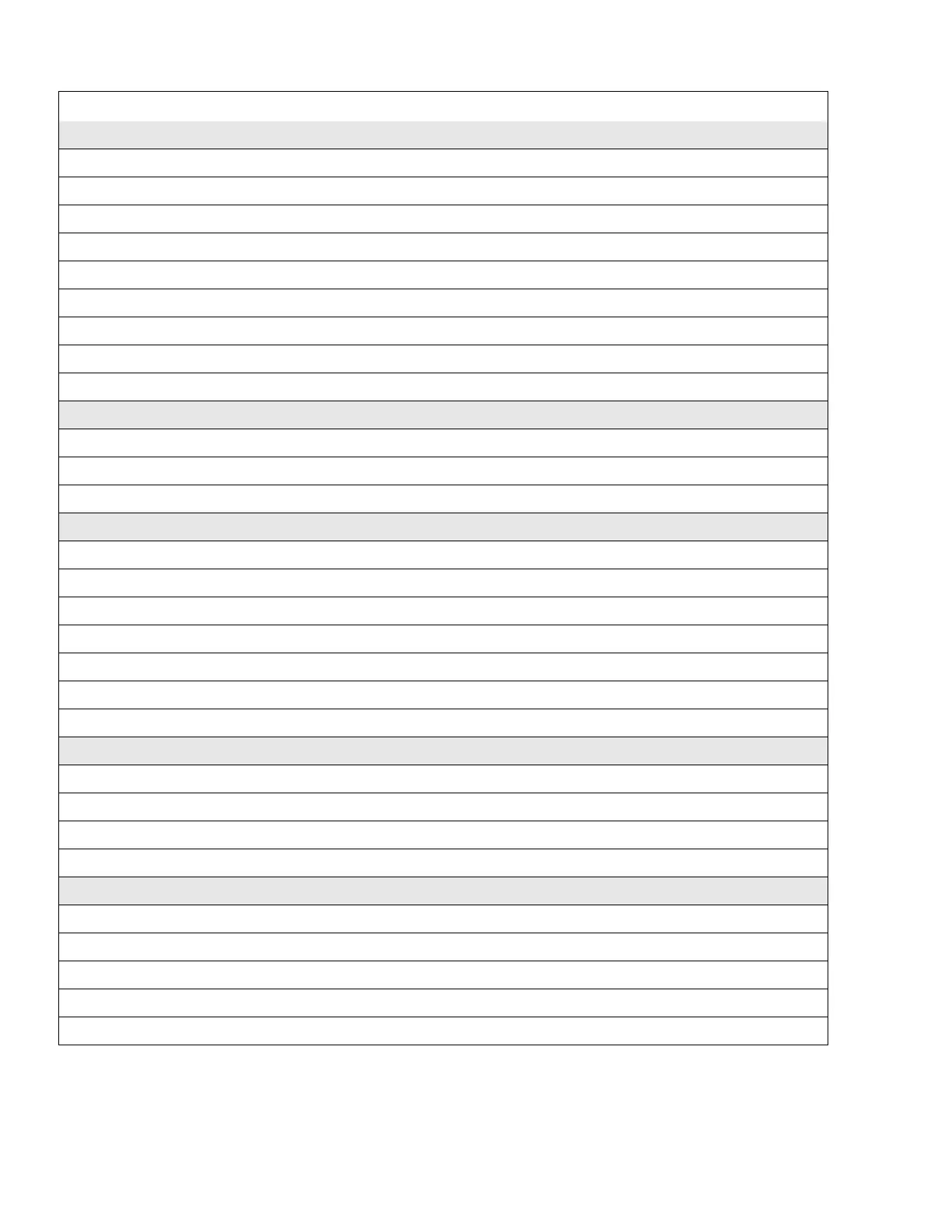

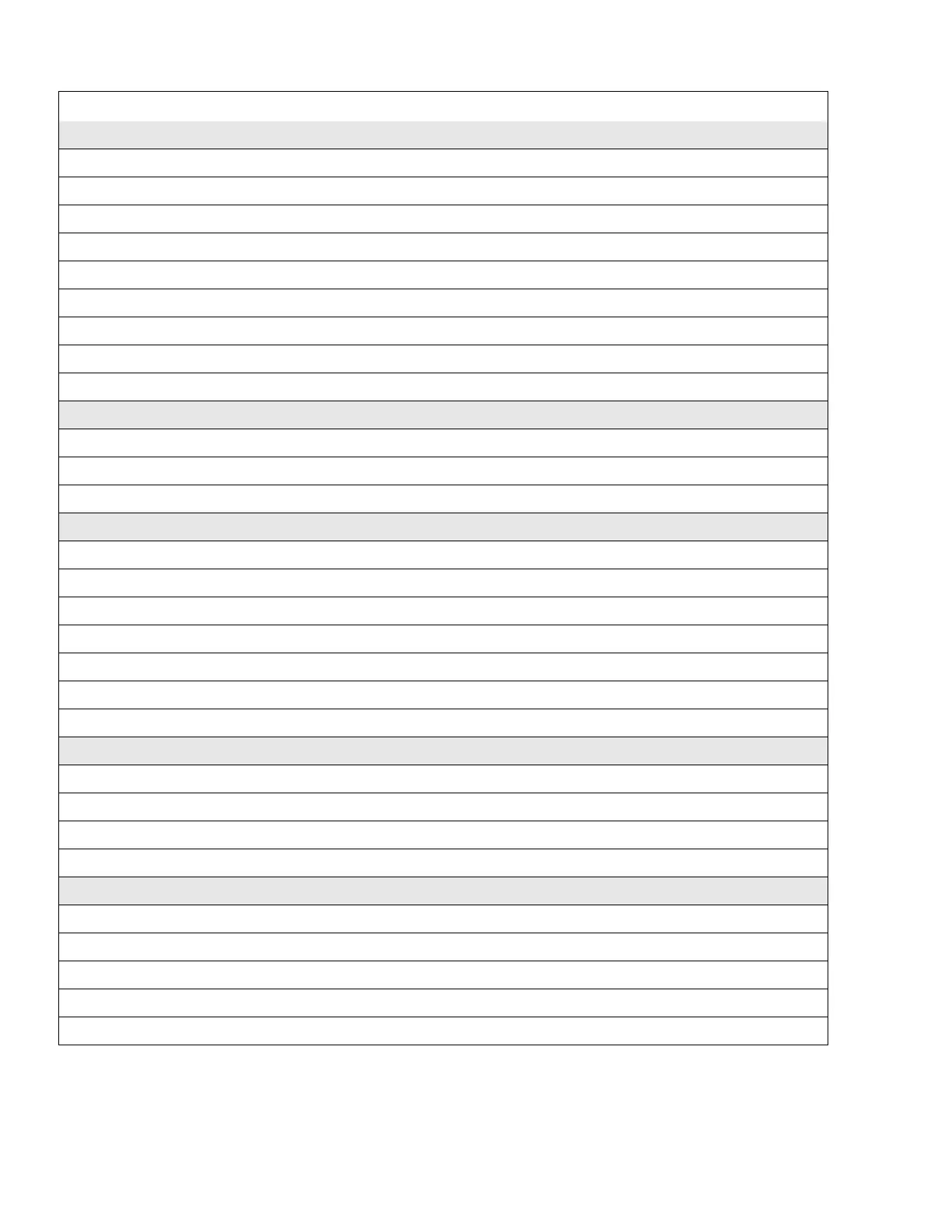

4.0 Miscellaneous Components

4.1 Check lid gas spring Each

4.2 Check lid seal for damage Each

4.3 Check inflatable seal for leaks Each

4.4 Inspect drip pan for cracks Each

4.5 Check entire unit for evidence of fluid leaks Each

4.6 Check all hose clamps and air line fittings 1x/year

4.7 Inspect lid latch gap Each

4.8 Inspect lid assembly (seal and header block) Each

4.9 Inspect all trays and aspirators for damage Each

5.0 Component Tests

5.1 Verify output of air compressor 1x/year

5.2 Verify output of high pressure pump 1x/year

5.3 Perform LS6 switch test Each

6.0 Control

6.1 Verify proper operation of printer Each

6.2 Verify all touch pads function properly Each

6.3 Verify date and time are correct Each

6.4 Verify operation of battery-backed RAM Each

6.5 Verify proper operation of buzzer Each

6.6 Check calibration of pressure transducer 1x/year

6.7 Verify operation of thermocouples 1x/year

7.0 UV Lamp Assembly

7.1 Replace UV Monitor with a recalibrated monitor 1x/year

7.2 Replace UV Lamp 1 x/year

7.3 Clean quartz sleeve 1 x/year

7.4 Replace quartz sleeve 1x every 2 years

8.0 Final Checkout and Test

8.1 Clean dirt and lint from control components Each

8.2 Reinstall any panels removed Each

8.3 Verify unit has proper labels Each

8.4 Run Diagnostic Cycle Each

8.5 Run Liquid Chemical Sterilant Processing Cycle Each

Table 4-1. Preventive Maintenance Schedule

Service Required Frequency

Loading...

Loading...