S - 66 | English English | S - 67

When mounting a front wheel with hub dynamo make sure the hub dynamo’s

connection terminal is on the right side in direction of motion. The connection

terminal has to be aligned with the front wheel fork in a way that it points slightly

backwards and upwards. Do not try to turn the connection terminal after having

fixed the front wheel in the fork.

If your front wheel has no quick-release, you need a 15 mm open-end wrench

or ring spanner or still better a torque wrench to tighten the axle nuts.

Axle nuts have to be tightened alternately on both sides. Otherwise the hub

axle can twist with the lock washers and be subject to stress. The torque value is

20–25Nm.

After you have securely fixed the wheel in the fork, re-connect the plug of the

lighting cable to the connection terminal.

Finish by checking the front and rear lights on the bicycle by turning the front

wheel.

Caution:

When working in the

area of the rear wheel

hub and its gear

mechanism, be aware

of the risk of crushing

the fingers. Therefore,

do not turn the cranks

during the work or do

not push the bicycle

backwards.

Caution:

Do not pull the (disc)

brake lever with a re-

moved wheel and make

sure to mount the safety

locks when removing

the wheel

Danger:

If your bicycle has hydraulic disc brakes, do not place it upside down for

repair purposes, i.e. handlebars and saddle on the ground. This would

render the brake ineffective.

Tubeless Tyres (UST tyres)

Tubeless tyres are also referred to as “tubeless ready”. The rims are provided

with specific valves, have an entirely enclosed rim base and partly also a specific

rim shape. There is no inner tube.

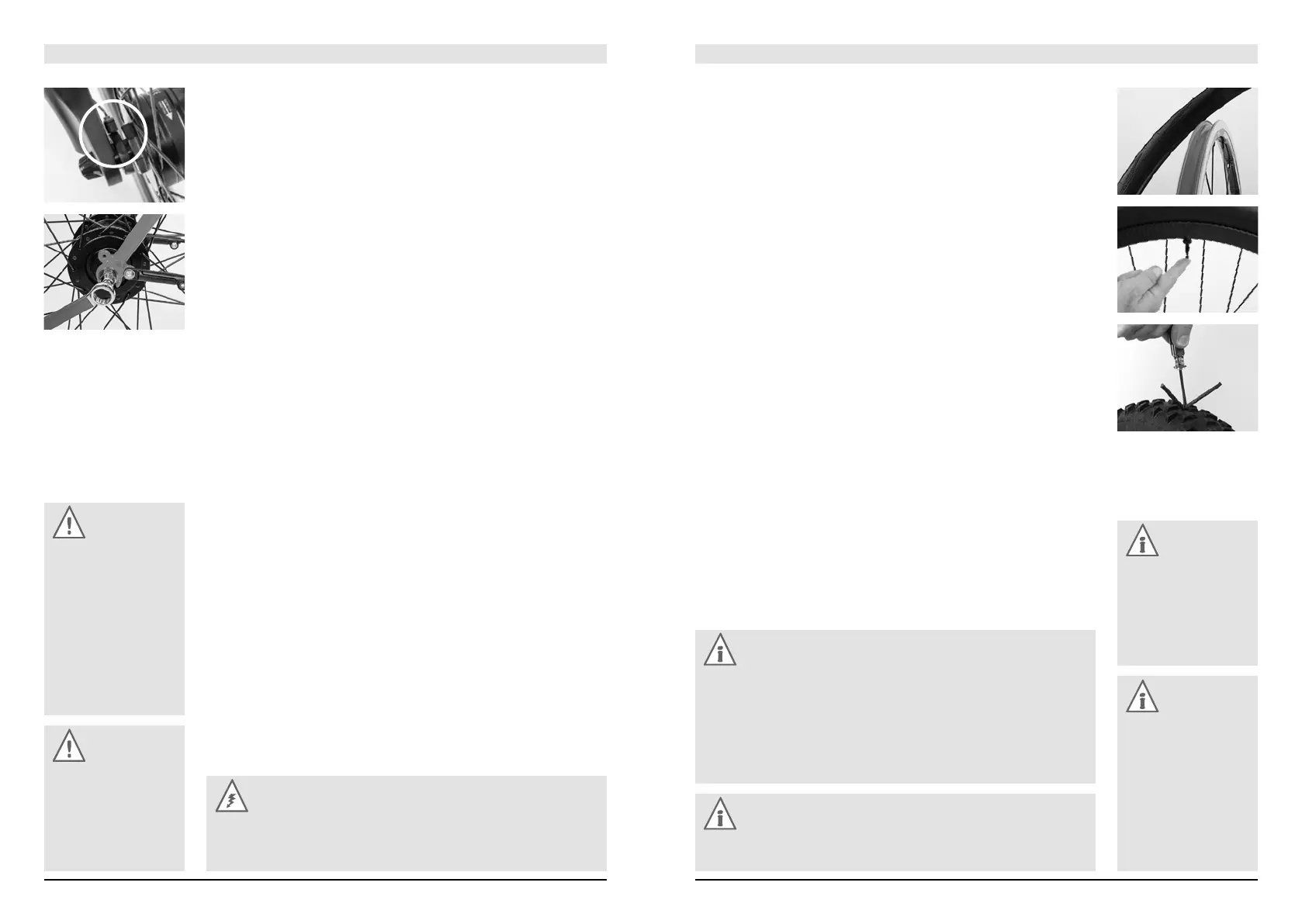

Tyre Removal

Deflate the tubeless/UST tyre completely. Press the tyre from one side towards

the centre of the rim, until the tyre bead is loose in the rim base.

Start removing the tyre close to the valve and lift one tyre side over the edge

of the rim with your fingers. After you have pulled the entire tyre side over the rim

edge press, if necessary, the other tyre side into the rim base and remove this side

also from the rim.

Puncture Assistance – Repair

In case of a puncture, tubeless tyres can also be used with inner tubes.

Remove any available perforating object from the tyre first and remove the valve

from the rim. Slightly inflate the new inner tube and place it in the tyre. Mount it

as described in the chapter “Removing Clincher and Folding Tyres”. You may

need tyre levers for this purpose.

You can repair larger tears or holes up to a maximum of 10mm in length

by using special tyre repair stuff such as “tyre repair strips”, “plugs” or “tubes”.

The area is prepared and the strip threaded on the tool. Press both strip and tool

into the defective area so that both ends of the strip are still just protruding on

the outside. Remove the tool. If necessary, fill in some new sealant or let existing

sealant run on the area. Inflate the tyre subsequently; during a ride this is best

done with a repair spray.

Note:

You can also inflate the tyre with the repair spray actually designed

for a repair during the ride. The spray provides an integrated puncture

protection. To do so slide the spray head on the valve. Align the bottle in a

way that the opening of the head is flush with the valve. Keep the top of

the head tight with one finger and press the bottle for about two minutes

against the head. Remove the bottle quickly from the valve. Then set off on

your bike for a few miles to make the latex milk spread inside the tyre.

Note:

Do not use tyre levers in order to avoid damage to the sensitive sealing lip

on the tyre bead!

Note:

It is recommended that

you use the tools of the

respective tyre manu-

facturer for removal as

they are designed to be

used together.

Note:

For tubeless tyres there

are specific patches that

are mounted on the in-

side. If need be, you can

also use a conventional

repair patch. Always

observe the operating

instructions of the repair

kit manufacturer.

Loading...

Loading...