S - 70 | English English | S - 71

Adjusting Conventional Headsets

For the adjustment of conventional headsets you need two flat, open-end

wrenches. Depending on the diameter of the headset the width of the open-end

wrench is 32 millimetres at least.

• Hold the front wheel tight between your legs, apply the wrench and release to

top counter nut.

• Turn the lower bearing cup race a little downwards. Do not tighten the bearing

cup race! This could damage the bearing immediately.

• Keep the bearing cup race tight with a wrench to maintain the adjustment.

Tighten the counter nut with the second open-end wrench against the bearing

cup race.

• Check it again for play. If the fork cannot be turned without any resistance and

play, the bearing is improperly adjusted. Adjust the bearing play once again.

This procedure of adjusting can take several attempts. The important thing is

that the bearing turns without any resistance and play. This is the only way to

ensure a long service life.

Danger:

Check the secure seat

of the stem after having

adjusted the bearings,

by holding the front

wheel between your

knees and trying to twist

the handlebar relative to

the front wheel. A loose

stem can throw you off

your bicycle

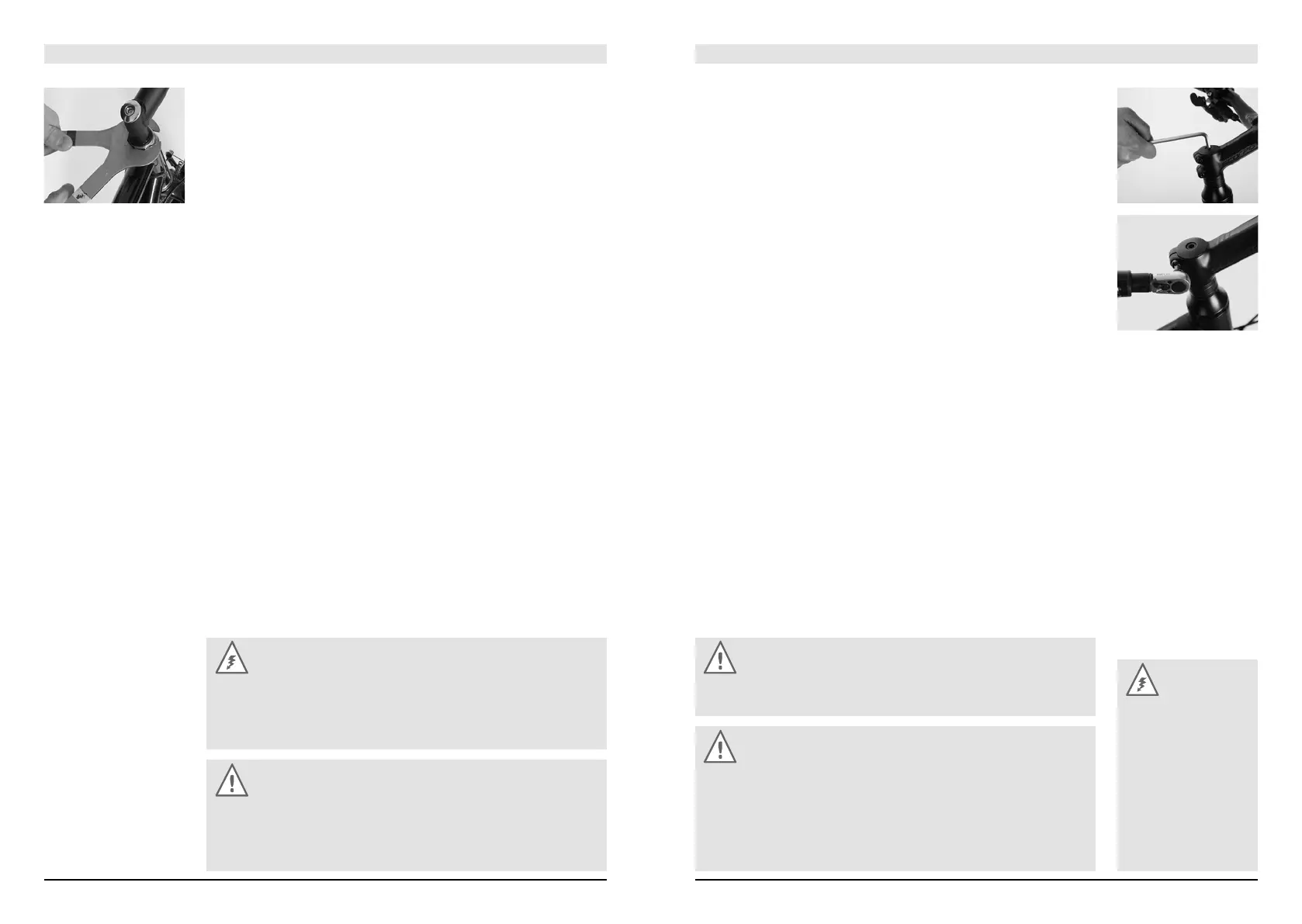

Adjusting the Threadless Headset: Aheadset

®

Headsets

The special feature of this system is that the stem is not encased by, but rather

clamped onto the steerer tube, which in this case is threadless. The stem is an

important part of the headset bearings. Its clamping force secures the bearing in

its set position.

Some frames are delivered with the headset partly integrated in the head tube.

The headset is then no longer visible. There is a seamless transition of spacer and

the fork into the head tube. The adjustment of the bearing is the same as with

the usual Aheadset

®

headset. But in this case you check the bearing play in the

transition area of frame and fork.

• Release the clamping bolt(s) located on the side of the stem by one to two

complete turns.

• Gently tighten a little the countersunk adjusting bolt on the top, i.e. by a quarter

turn at the most, by using an Allen key.

• Realign the stem with the frame so that the handlebar is not slanted when the

wheel points straight ahead.

• Retighten a little the clamping bolt(s) of the stem until the stem no longer turns

relative to the fork. Do not exceed the torque values specified by the stem

manufacturer, see the chapter “Recommended Torque Settings”.

• Check the headset for play, as described above. Do not overtighten the head-

set. Risk of headset failure.

Caution:

Do not overtighten the upper bolt, it only serves the purpose of adjusting

the bearing play, not of securing the stem!

Caution:

In the case of full carbon forks the torque values are often clearly below

the specifications of the stem manufacturers. A sufficient clamping is usu-

ally already achieved with inferior forces. Tighten carefully by approaching

the prescribed maximum torque value in small steps until the stem no

longer turns relative to the fork or front wheel. Too high torque values can

destroy the steerer tube!

Danger:

Check the secure seat of the stem after having adjusted the headset,

by holding the front wheel between your knees and trying to turn the

handlebars relative to the front wheel. Otherwise, a loose stem can cause

an accident.

Caution:

Adjusting the headset requires a certain amount of experience and should

therefore be left to your STEVENS dealer. If you want to try it on your own,

be sure to read the instructions of the headset manufacturer on our web-

site at www.stevensbikes.de/manual before doing any adjusting!

Loading...

Loading...