S - 60 | English English | S - 61

Repairing Punctures

Tyre punctures can happen to any cyclist. As long as you have the necessary

tools for changing tyres and tubes and a spare tube or a tyre repair kit, this need

not mean the end of your cycle tour, however. For bikes with quick-releases all you

need are two tyre levers made of plastic and a pump; if your wheels are secured

with nuts you also need a suitable wrench for removing the wheel.

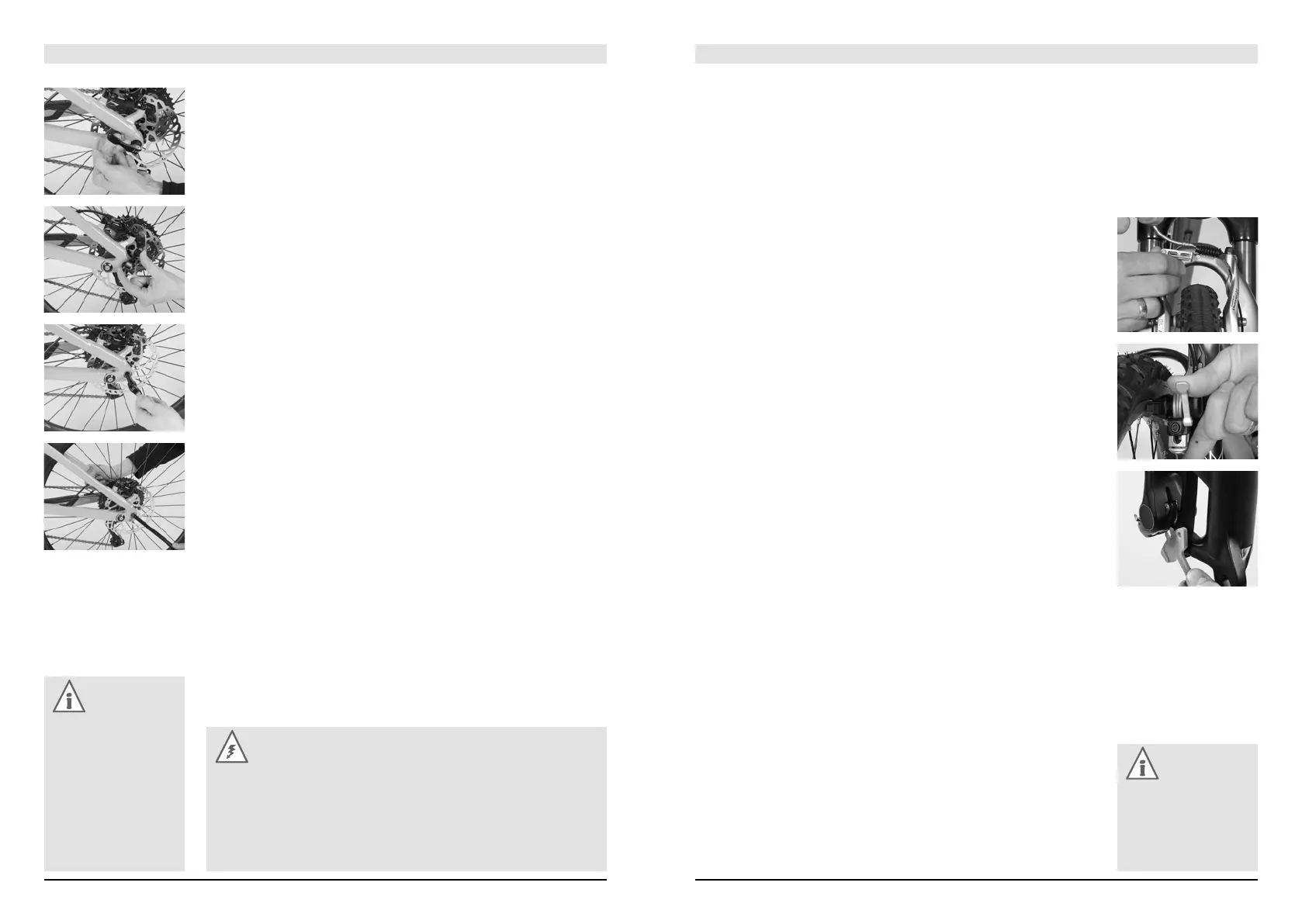

Wheel Removal

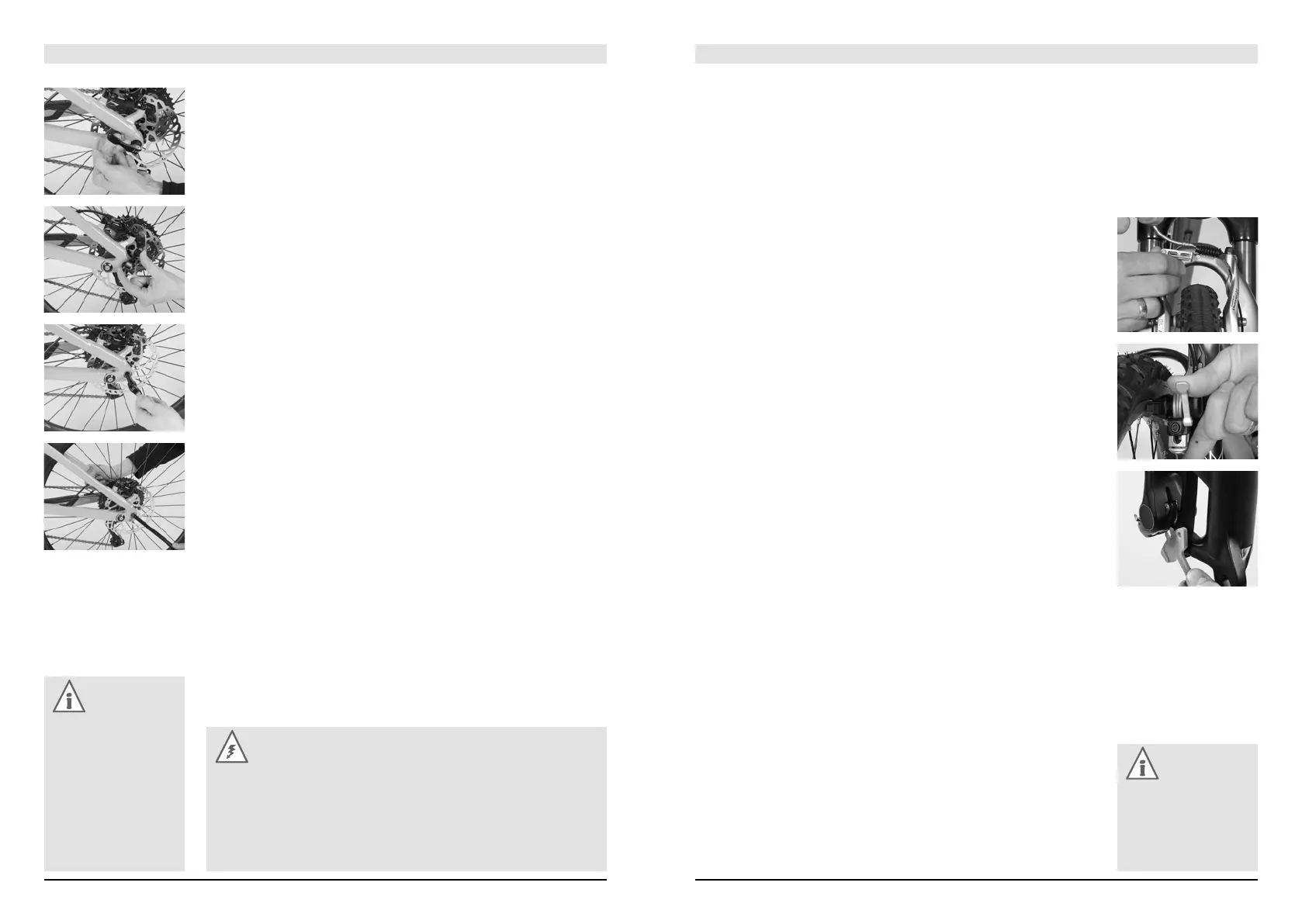

If your bicycle has cantilever brakes and V-brakes you first have to unhook

the brake cable from the brake arm. To do this grip around the wheel with one

hand and press the brake pads and arms together. In this position it should be

easy to disengage the usually barrel-shaped nipple or, in the case of V-brakes,

the outer cable.

In the case of hydraulic rim brakes deflate the tyre completely or dismount

one brake unit, if you have a quick-release brake, before removing the wheel.

Be sure to read the instructions of the brake manufacturer on our website at

www.stevensbikes.de/manual. Make sure to fix the brake pad exactly in parallel to

the braking surface of the rim when mounting this brake unit!

If you have disc brakes and dismount the wheel for the first time, check the

exact position and condition of the brake pads and/or wear indicators (ear or nose-

shaped metal protrusions). This will help you to verify subsequently, whether the

brake pads are still in the proper position after dismounting. Open the quick-re-

lease of the wheel, as usually. Compared to all other brake systems the disc brake

does not interfere with the removal of the wheel; the wheel can immediately be

removed from the drop-outs.

Do not activate the brake lever as long as the wheel is dismounted; this would

change the position of the brake pads. This can make the brake drag along the

disc after the remounting.

Note:

Insert the transport

locks in the brake

callipers of the disc

brake when you have

dismounted the wheel.

Note:

Manufacturers of

thru-axle systems

usually deliver their

products with detailed

operating instructions.

Read them carefully

before removing the

wheel or doing any

maintenance work.

Wheel Removal

If you have a rigid thru-axle system, open the quick-release lever fully. If there

are levers, loosen the axle by turning.

Loosen all types of thru axles anticlockwise. After the thru-axle thread has fully

loosened from the nut thread, you can pull out the thru axle.

Hold the frame and the wheel tight while doing so, to ensure that parts do not

fall down or topple over.

Danger:

To mount the axle only use the tools recommended by the manufacturer.

Make it a rule to use a torque wrench. Tighten carefully by approaching

the prescribed maximum torque value in small steps (0.5 Nm increments)

and check in between the proper fit of the component. Never exceed the

maximum torque value indicated by the manufacturer! A too tight fixing of

the axle can impair the axle or the frame.

Loading...

Loading...