Assembly & Installation

B3.1 Note: On bins 30’ and larger with a

double-bracketed track, a gap has been

left to prevent interference between

vertical seam on sidewall sheets and track

brackets. Install first section of track with

bin wall seam in place of missing bracket.

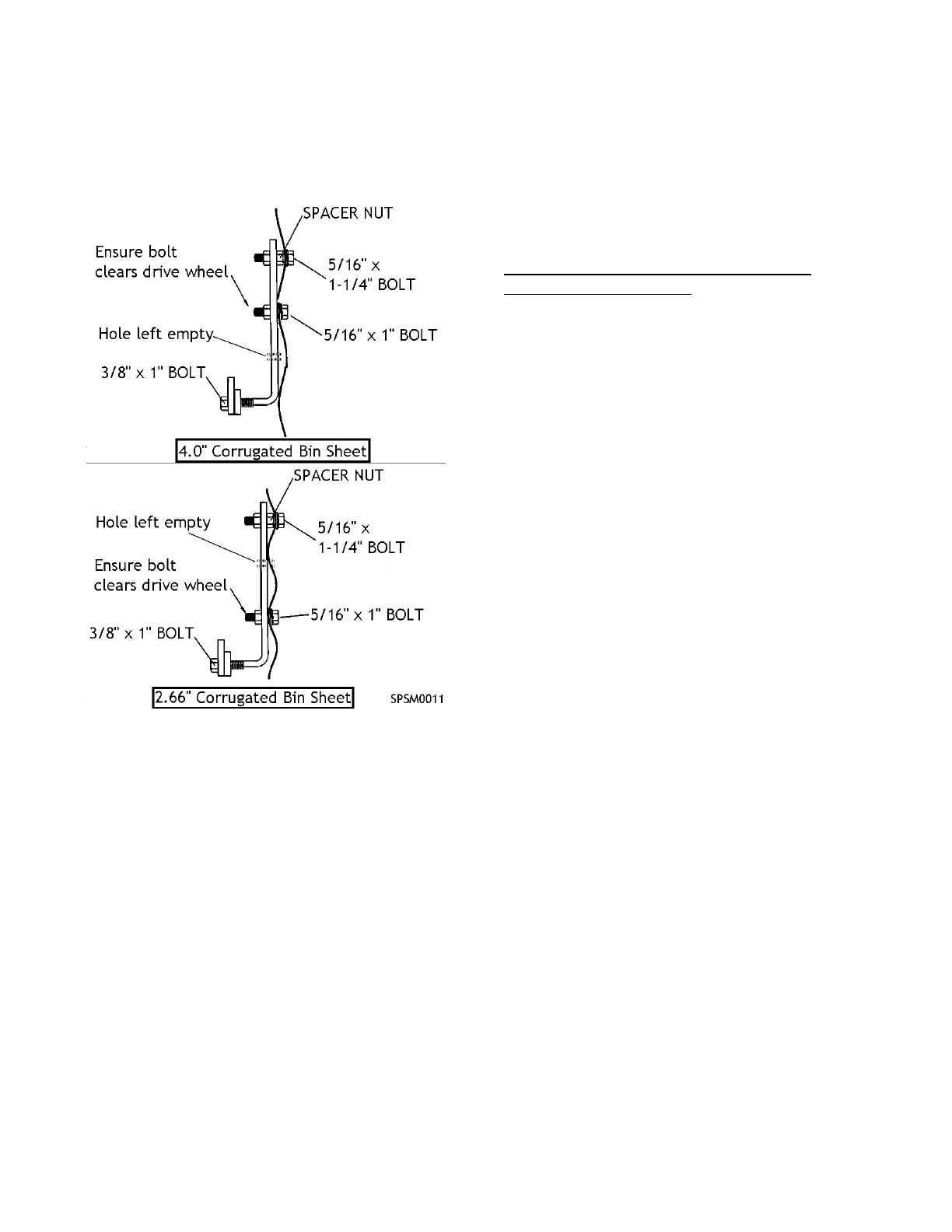

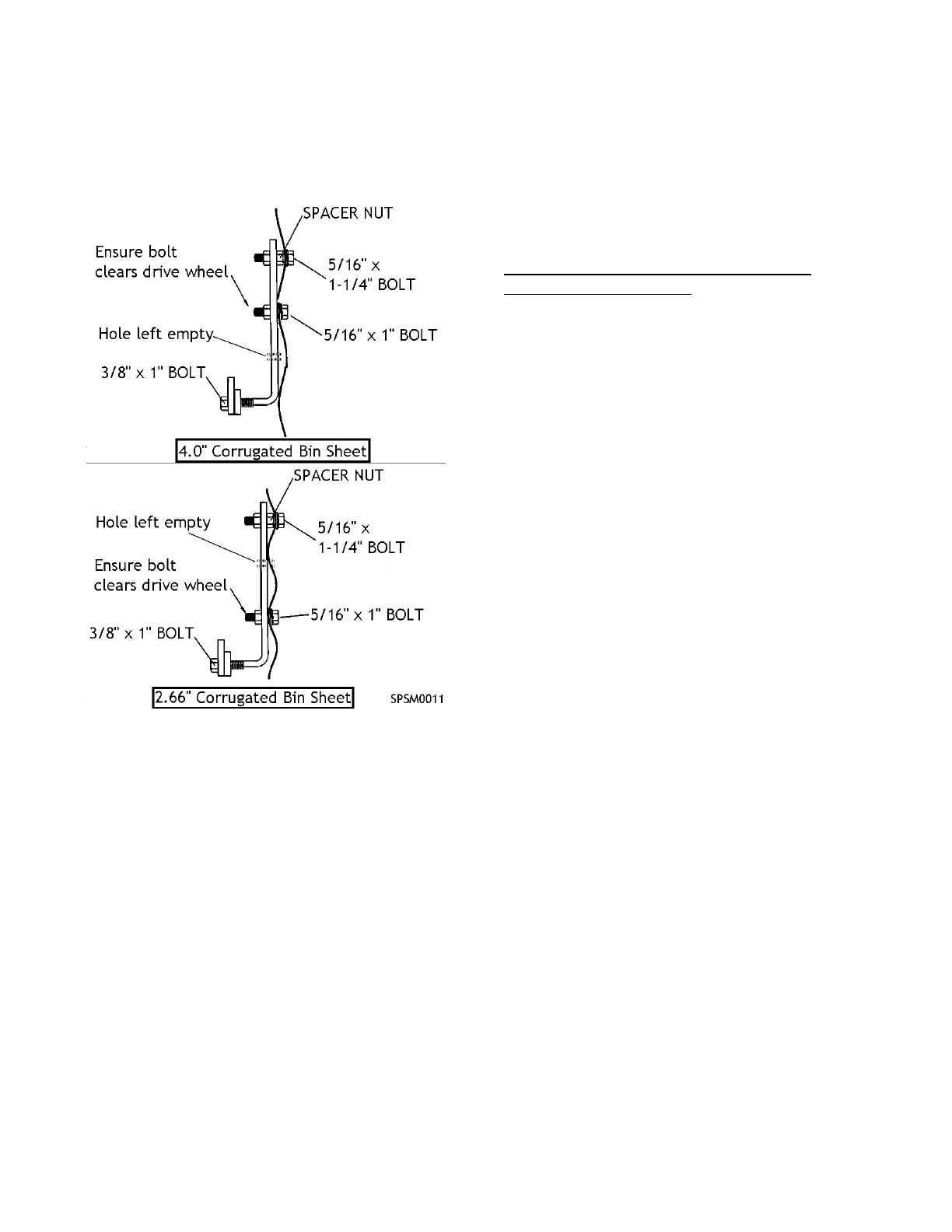

Figure 3.

Figure 6 - Side View of Track Mounted on Sukup Bin

Sheets Not Punched for Track and Sheets from Other

Companies

B4 Mount remaining track sections using steps B2-

B3, joining track sections together with 3/8” x 1”

bolt and 3/8” lockwasher and nut. Tighten using

9/16” wrench. Figure 5.

B4.1 Note: Ensure these bolts are pointing to

outside (toward bin sidewall) to avoid

obstructing machine movement.

B5 After all track sections are in place, drill second,

lower bolt holes through bin sheets using track

brackets as pattern. Figure 6.

B5.1 Note: Drill through middle bracket holes

only when dealing with 4.0” cor. sidewall

sheet.

B5.2 Note: Drill through bottom bracket holes

only when dealing with 2.66” cor. sidewall

sheet.

B6 Insert 5/16” bolt no longer than 1” into newly

drilled holes. If needed, insert a longer bolt

pointed to outside to avoid obstructing machine

movement and screw on 5/16” nuts. Tighten

using 1/2” wrench.

B6.1 Note: Leave unused track bracket holes

empty. Figure 6.

B7 Tighten 5/16” nuts on top bolts through track

brackets using 1/2” wrench.

B8 Ensure entire length of track and bin wall is free

of any obstructions that could hinder movement

of machine through bin.

C. Installing Track When Holes for Track

Brackets Must Be Drilled

C1 Place first segment of track in bin.

C2 Drill holes in top bin sheet to match holes on

each bracket:

C2.1 When drilling 4.0” Cor. sidewall sheets,

use top and bottom track bracket holes as

guide as shown in Figure 4.

C2.2 When drilling 2.66” Cor. sidewall sheet,

use bracket holes as guide to drill through

corrugation hills on sheet.

C3 Insert 5/16” x 1-1/4” bolt through top bolt holes.

Figure 6.

C4 Mount first segment of track over bolts and

screw on 5/16” nuts. Figure 6.

C5 Insert 5/16” x 1” bolts in lower holes of track

bracket and add 5/16” nuts. Tighten using 1/2”

wrench. Figure 6.

C5.1 Note: Leave unused track bracket holes

empty. Figure 6.

C6 Mount remaining track sections using steps C2-

C5, joining track sections together with 3/8” x 1”

bolts and 3/8” lockwashers and nuts. Tighten

using 9/16” wrench. Figure 5.

C6.1 Note: Ensure these bolts are pointing to

outside (toward bin sidewall) to avoid

obstructing machine movement.

C6.2 Note: Because of the large variation in

diameter from bin to bin, it may be

necessary to use a splice to join the last

section of track. These splice sections are

available at no charge by contacting

Sukup Manufacturing Co. by mail at Box

677, Sheffield, Iowa 50475; by phone at

641-892-4222; or by e-mail at

info@sukup.com.

C6.3 If splice is required, bolt splice sections in

place and tighten.

C7 Ensure entire length of track and bin wall is free

of any obstructions that could hinder movement

of machine through bin.

Loading...

Loading...