Assembly & Installation

35 Remove cotter and clevis pins from holes on 1”

tube coupler attached to gearmotor shaft. Save

pins. Figure 20.

36 Slide 1” tube coupler onto crosstube shaft and

insert 1/4” x 1-3/4” clevis pin and 1/16” x 3/4”

cotter pin from step 35 into holes to connect

crosstube shaft and gearmotor. Figure 20.

37 Insert 5/16” x 3/4” bolts and 5/16” lockwashers

from step 34 through holes in center hanger and

screw into holes on gearmotor. Check vertical

alignment. Tighten using 1/2” wrench. Figure 20.

38 Adjust gearmotor placement so no binding exists

on pins and center hanger and so pillow block

and center hanger do not touch tube. DO NOT

ATTEMPT TO ADJUST gearmotor shaft by

tapping on shaft with a hammer.

39 Tighten 4 set screws in pillow block bearing (2 on

each end) using 1/8” hex (Allen) wrench. Tighten

bolts (step 33) using 9/16” wrench. Tighten set

screws on pillowblock. Figure 20.

40 Screw hanger pipe tightly into 1” threaded hole

on cast electric junction box.

40.1 Note: Ensure threads are fully engaged,

as they will hold weight of Fastir.

Figure 20.

41 Slide cast bushing and brass washer onto hanger

pipe so they rest on junction box. Figure 20.

42 Slide end of hanger pipe up through bottom of

hole in center hanger so junction box is inside

center hanger. Figure 20, Figure 21.

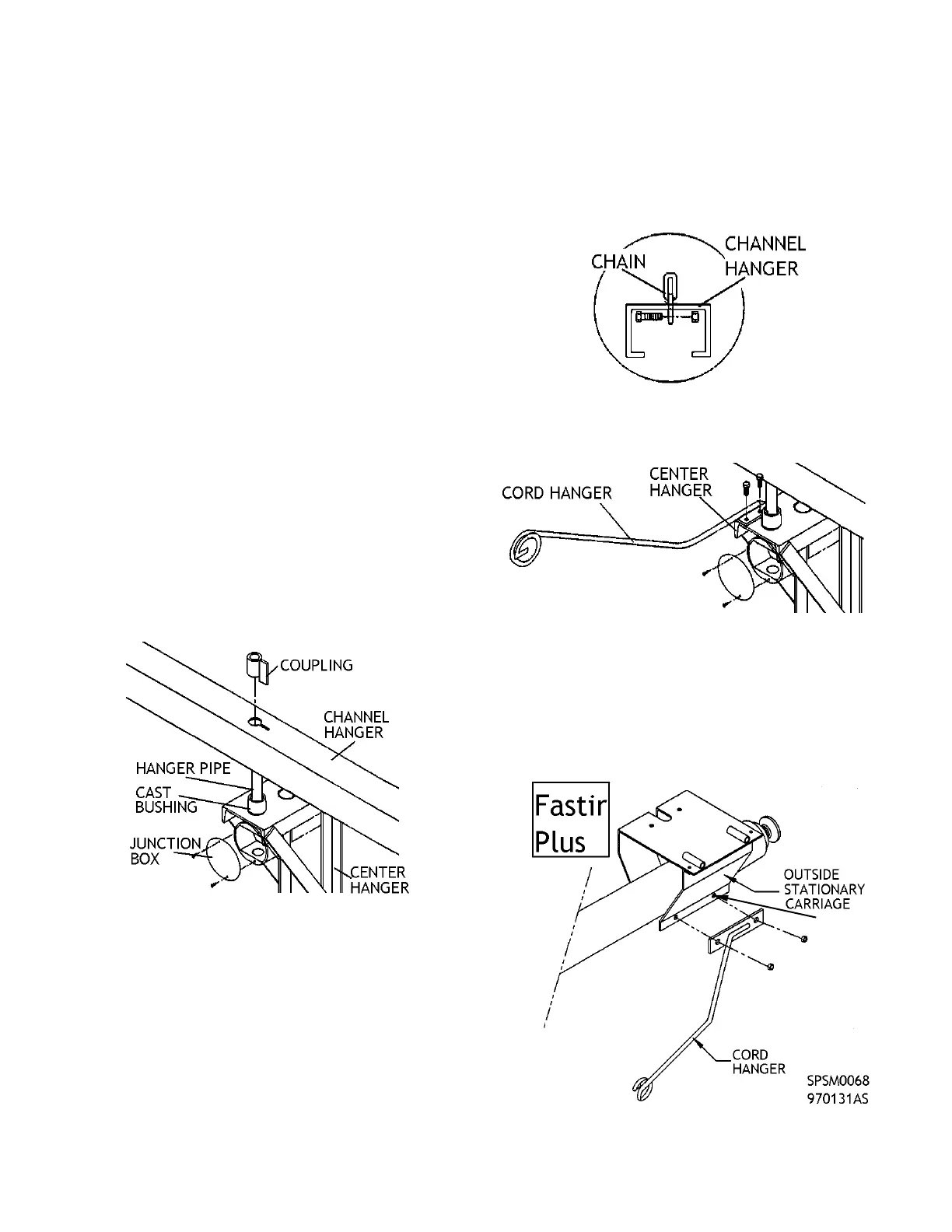

Figure 21 - Placement of Cast Electric Junction Box on

Center Hanger

42.1 Note: Do not thread rotating contact

into cast electric junction box until

machine is raised in bin (see page 31

for rotating contact instructions).

Failure to heed this note can result in

rotating contact binding and breaking.

43 Slide channel hanger over hanger pipe. Figure

20, Figure 21.

44 Screw coupling onto hanger pipe ensuring tab

on coupling fits in slot on channel hanger.

Figure 20, Figure 21.

45 Thread a liquid-tight elbow (not provided) into

top of coupling. Ensure threads are seated

properly and tighten well. Figure 20.

46 Bolt chains onto each end of channel hanger

using 3/8” x 1” bolt and 3/8” nut. Tighten using

9/16” wrench. Figure 20, Figure 22.

46.1 Note: Center hanger will hang slightly tilted.

This is normal.

Figure 22 - Chain Placement in Channel Hanger

47 Bolt cord hanger to top of center hanger with 5/16” x

1” bolts. Tighten using 1/2” wrench. Figure 23.

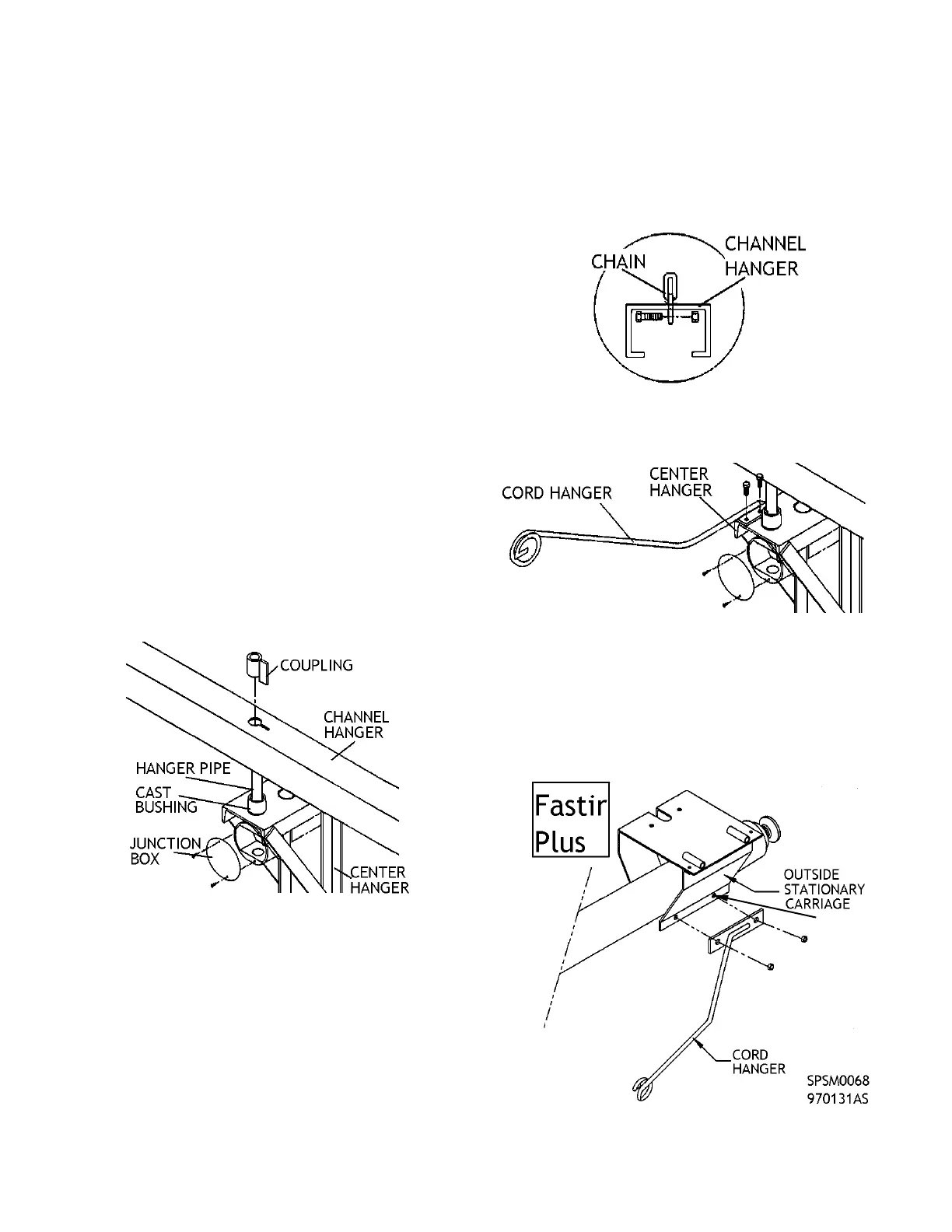

Figure 23 - Cord Hanger Placement on Machine

47.1 Fastir Plus Only: Bolt cord hanger to

bottom plate of stationary outside carriage

using existing 1/2” carriage tightening

bolts (double nut). Figure 24.

47.2 Note: Position cord hanger behind

direction of travel of crosstube to keep

cords away from augers.

Figure 24 - Cord Hanger Placement on Fastir Plus Unit

EXISTING 1/2"

CARRIAGE

BOLT

Loading...

Loading...