MORTEXPRODUCTSINC.501TERMINALRDFORTWORTH,TEXAS76106 Page12

Check to see if airflow through the system is good. There should

be no dirty coils or air filters. Also check for proper CFMs

readings across the system.

Make sure there's the right amount of refrigerant charge in the

system (this step may require weighing out the refrigerant in the

system). Once you've added or removed charge as necessary,

check the pressures, subcooling and superheat again. If there is

no change then it is probably the TXV.

Check the evaporator coil and remove the TXV's sensing bulb

from the suction line.

Check the subcooling, superheat and pressures again. If there's

no change, that's a further indication of a TXV problem.

Another test is to put the sensing bulb in ice water and checking

the pressures, superheat, and subcooling again. If they don't

change, it's a bad TXV.

When a non-bleed expansion valve (TXV) is specified in a

Summit AC or HP Rating, the following assumptions are made:

a) The TXV is a field or factory installed accessory to be field

or factory installed in accordance with recommended TXV

practice.

b) The combination of this non-bleed valve and the

compressor in the outdoor unit results in a system that

operates with a loaded condition on startup.

c) The outdoor unit is capable of starting against this loaded

condition or a hard start kit is to be field installed.

APPLICATION DATA:

R72DB0005 (R-22) 15% Bleed Non-Adjustable - 1.5-3.0 Ton

“T” Valve Letter Code

R72DB0003 (R-410A) 15%-Bleed Non-Adjustable-1.5–2.5 Ton

“D” Valve Letter Code

R72DB0004 (R-410A) 15%-Bleed Non-Adjustable-3.0–5.0 Ton

“Y” Valve Letter Code

Inlet Fitting Male Rotalock / Outlet Fitting Female swivel nut.

R72DB0006 (R-22) 15% Bleed Non-Adjustable - 3.0-5.0 Ton

“X” Valve Letter Code

R72DB0044 (R-410A) Non-Bleed Adjustable - 3.0-6.0 Ton

“Z” Valve Letter Code

Inlet Fitting Male Rotalock / Outlet Fitting Female swivel nut.

TXV TROUBLE SHOOTING:

Changing parts might be the first reaction, BUT…

1. May not be necessary and…

2. Does not always solve the problem.

SUPERHEAT AND SUCTION PRESSURE

LOW SUCTION PRESSURE – HIGH SUPERHEAT

POSSIBLE CAUSES:

1. Undersized valve

2. High superheat adjustment

3. Evaporator pressure drop – no external equalizer

4. External equalizer location – needs to be located on suction

line after the last feeder tube.

5. Restricted or capped external equalizer

6. Low refrigerant charge

7. Plugged dryer or strainer

8. Low pressure drop across valve:

a. Plugged dryer or strainer

b. Low condensing temperature

HIGH SUCTION PRESSURE – LOW SUPERHEAT

POSSIBLE CAUSES:

1. Oversized valve

2. TXV seat leak

3. Low superheat adjustment

4. Bulb installation:

a. Poor thermal contact

b. Warm location

5. Bad compressor – low capacity

6. Incorrectly located external equalizer line – needs to be

located on suction line after the last feeder tube.

LOW SUCTION PRESSURE – LOW SUPERHEAT

POSSIBLE CAUSES:

1. Low load:

a. Not enough air

b. Dirty air filters

c. Air too cold

d. Coil icing or frosting

2. Poor air distribution

3. Improper compressor evaporator balance – coil too big or

small or incorrect balance on heat pump systems.

4. Oil is trapped in the evaporator

Check these things before removing the TXV

1. Remove the sensing bulb and hold in your hand. The high

side pressure should drop and low side pressure should

increase as the TXV opens.

2. Loosen the flare nut on the TXV external equalizer tube

that is connected with a flare nut on the suction line. If you

get a lot of pressure when the nut has been loosened then

tighten the nut. If you get a slight pressure or no pressure;

the Schrader valve stem is not being depressed. Install a

anti blow back fitting to the external equalizer line of the

TXV to depress the Schrader valve stem and check for

proper operation of the TXV.

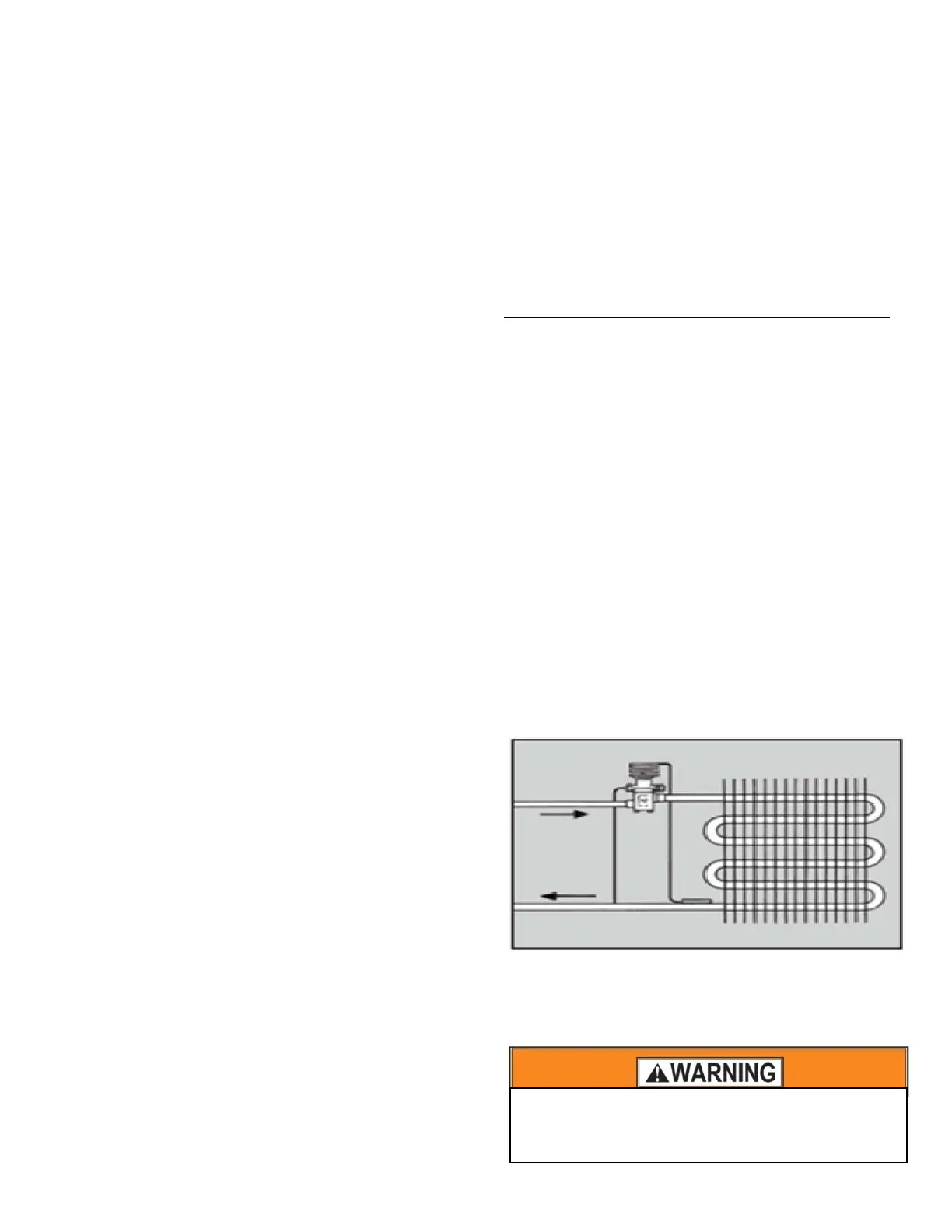

Figure 8: TXV Sensing Bulb Location

INSTALLATION NOTES:

With reference to the Figure 8, the TXV assembly is to be

installed between the distributor and the existing liquid line

Coil is pressurized with nitrogen. Relieve pressure before

installing TXV by depressing Schrader valve on coil

manifold.

Loading...

Loading...