MORTEXPRODUCTSINC.501TERMINALRDFORTWORTH,TEXAS76106 Page13

Field Installed:

1. After coil pressure has been relieved, turn the female swivel

nut counter-clockwise to remove.

2. If Flowrator Distributor Assembly is being replaced by a

TXV, remove the piston orifice from the flowrator

distributor assembly using a small diameter wire or paper

clip.

3. Attach the TXV by connecting the female swivel nut on

TXV outlet to the flowrator distributor (aligning Teflon seal

first) and torque swivel nut to 10-30 ft. lbs.

4. Attach liquid line with female swivel nut to male rotalock

fitting on TXV inlet (Aligning Teflon seal first) and torque

swivel nut to 10-30 ft. lbs.

5. Remove the cap on Schrader valve port on coil manifold.

Attach equalizer tubing with 1/4” female flare nut that

includes depressor to this male Schrader port. Torque nut

to 10-30 ft. lb

6. Install the TXV bulb to the suction manifold of coil or the

suction line using the two bulb clamps furnished with kit.

a. Bulb should be installed on a horizontal run of the

manifold if possible. On line less than 7/8” OD the

bulb may be installed on top of the line. With 7/8” OD

and over, the bulb should be installed in a position at

about 4 or 8 o’clock.

b. If bulb installation is made on a vertical run, the bulb

should be located at least 6 inches from any bend, and

on the tubing side opposite the plane of the bend. On

vertical bulb installations, the bulb should be

positioned with the bulb capillary tube at the top.

c. The bulb should be insulated using thermal insulation

to protect it from the effect of the surrounding ambient

temperature.

7. After completing installation of TXV (including equalizer

tube), it will be necessary to leak check the coil and

evacuate the coil through the service access fittings of

liquid and suction line valves.

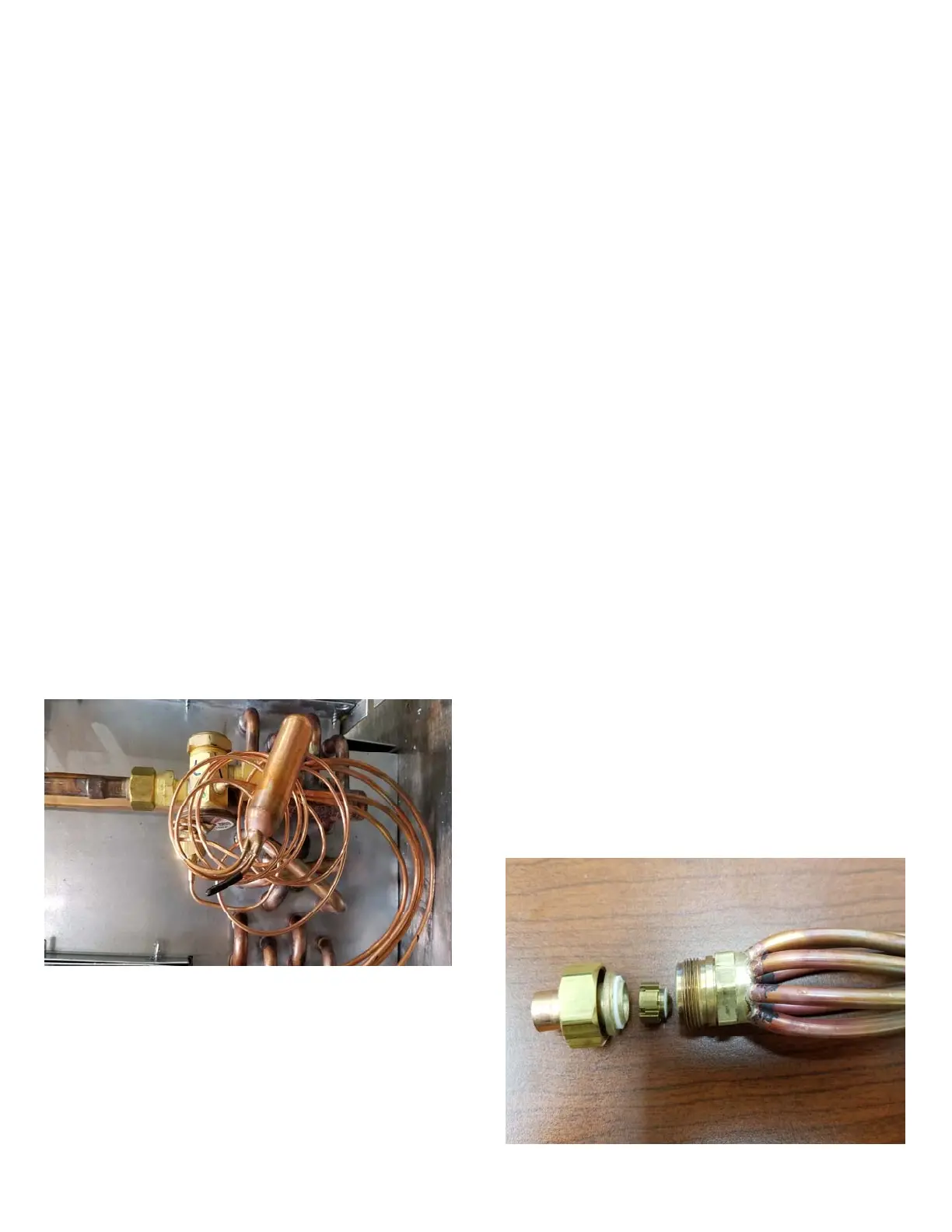

Figure 9 Typical TXV Connections

SPECIAL INSTRUCTIONS FOR COILS WITH

FLOWRATOR DISTRIBUTOR ASSEMBLIES

The sizing of the orifice piston should be based strictly on the

rated capacity of the outdoor unit and coil match.

Summit provides capacity performance ratings that match both

same size and upsized coils with specific manufacturer’s

outdoor units. At the Summit distributor’s request, the orifice

piston is selected and installed in each coil for the specific range

of cooling capacities likely to be encountered. The factory

installed orifice piston size is marked on the flowrator

distributor assembly and on the front of the coil carton.

When using this coil with an outdoor unit of another capacity,

select an orifice piston from the table below if the capacity

range for the coil and outdoor unit to be used differs.

Failure to install the proper orifice piston can lead to poor

system performance and possible compressor damage. A

variation of one piston size is not normally critical. Summit

reserves the right to substitute a factory installed piston one size

smaller or greater if the piston size ordered is out of stock.

A selection of replacement orifice pistons is available from your

Summit supplier.

FLOWRATOR TO TXV CONVERSION:

While thermal expansion valves can be factory installed, they

are normally available in kit form for field installation. For kit

version, follow the installation instructions provided with the

kit. Normally these can be field installed before system is

charges without requiring cutting and brazing. BE SURE

FLOWRATER PISTON HAS BEEN REMOVED FROM

THE FLOWRATER DISTRIBUTOR BODY PRIOR TO

INSTALLATION OF EXPANSION VALVE.

ORIFICE PISTON REPLACEMENT:

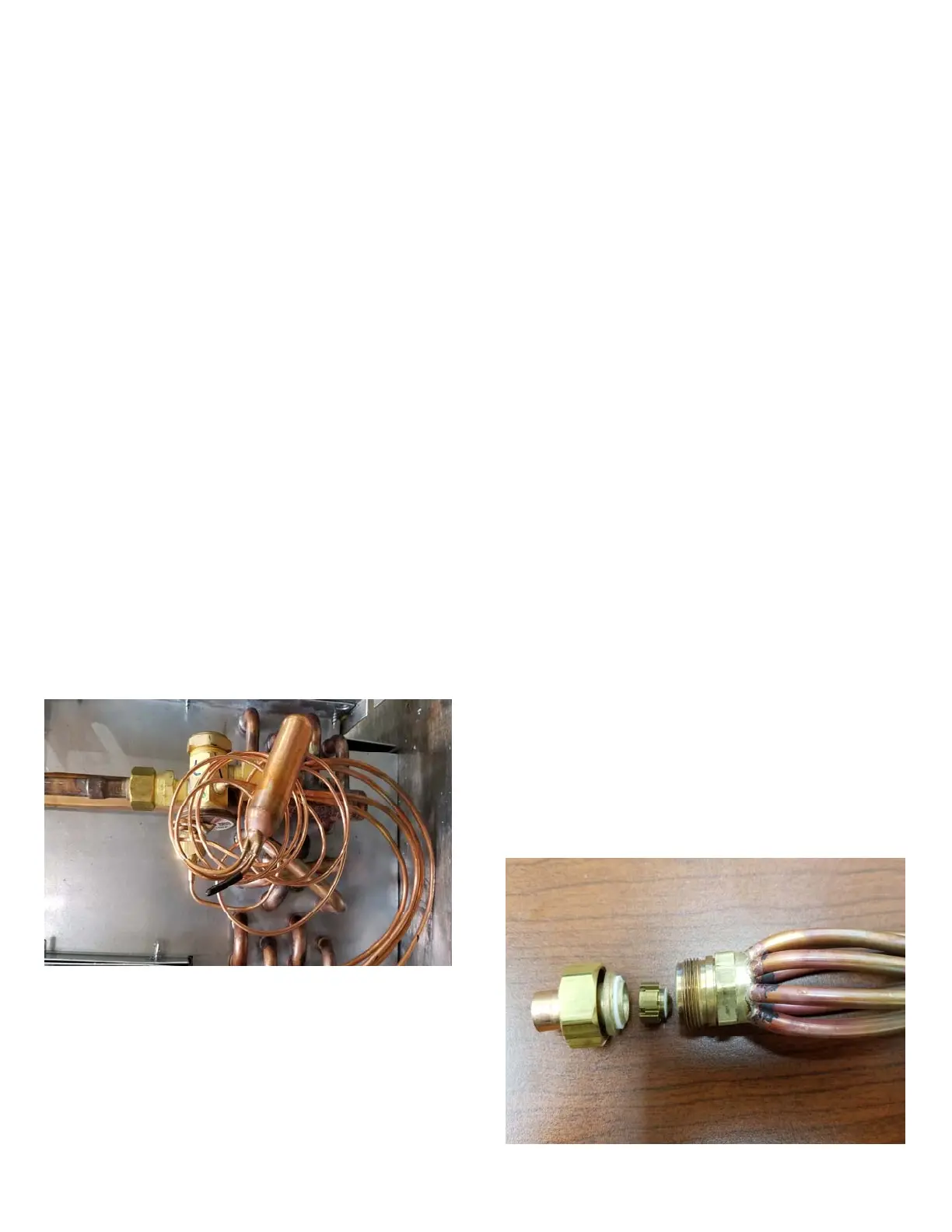

If the flowrator distributor assembly is being used the piston is

to be installed as shown in Figure 10 in the distributor body then

the existing liquid line attached to the flowrator distributor.

1. After coil pressure has been relieved, turn the female swivel

nut counter-clockwise to remove.

2. Remove the piston from the flowrator distributor fitting

using a small diameter wire or paper clip. ALWAYS

REMOVE PISTON FROM DISTRIBUTOR BODY

WHEN TXV IS INSTALLED).

3. Replace the orifice piston with the correct piston for the coil

you are using. Make sure the tapered end of the piston is

facing the feeder tubes on the distributor body.

4. Turn the female swivel nut on clockwise the flowrator

distributor (aligning Teflon seal first) and torque swivel

nut to 10-30 ft. lbs.

5. After completing the replacement of the orifice piston, it

will be necessary to leak check the coil and evacuate the

coil through the service access fittings of liquid and suction

line valves.

Figure 10: Flowrator Distributor

Loading...

Loading...