MORTEXPRODUCTSINC.501TERMINALRDFORTWORTH,TEXAS76106 Page33

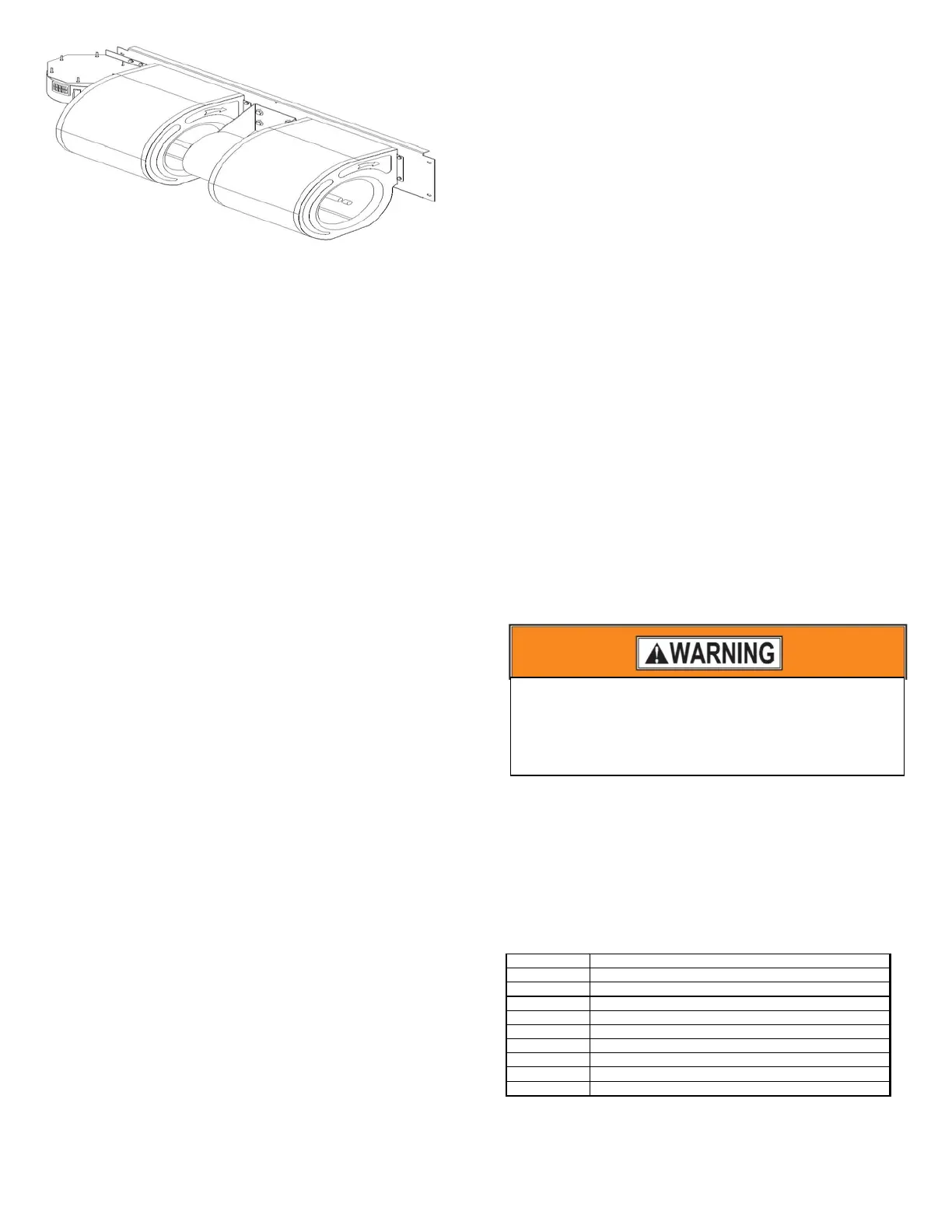

Figure 32: Constant Torque Blower Assembly

13 Remove both of the blower housings by sliding the blower

wheels “off” the motor shaft.

14 Replace both of the blower housings by sliding the blower

wheels “on” the motor shaft.

15 Set the new blower motor on the mount bracket. Place one

end of the retaining clip into the notch on the motor mount

bracket. Use a straight edge screw driver and a mallet on

the “U” shaped part of the retaining clip to push the clip

down and into the notch on the other side of the bracket.

16 Set the blower housing in the correct position on the blower

mount plate and secure the blower housings with the screws

that were removed.

17 Rotate the blower housing so you are looking at the wheel

from the discharge of the blower. Center the blower wheels

in the housing then use a hex key to tighten the set screws

and secure the blower wheels to the motor shaft.

18 Grab the blowers and lift the panel up, push in on the

bottom, then pull down to set the blower mount plate in

place.

19 Replace the two screws on the blower mount plate located

on the right side, the left side, the screw on the top center

and the screw in the control box. Refer to Figures 31 and 32

for screw locations.

20 Place the motor wires into the control box and replace the

strain relief that is securing the wires to the control box.

21 Reconnect the blower motor power wires from the relay

and the terminal block.

22 Replace the control box cover and secure with the screws

that were removed.

23 Close the ceiling access panel and secure the panel with the

thumb screws that were removed.

24 Turn on all electrical supply circuits to the Air Handler unit

at the main service (House Circuit Breaker) panel.

25 Set the thermostat to the desired temperature.

Typical Heat Pump - Heating/Cooling Thermostat Wiring

Connections

1. Remove the blower access panel.

2. Remove the control box cover.

3. Install a grommet or a strain relief in the 9/16”

diameter hole on the top and the right side of the air

handler casing to protect the thermostat wire cable.

4. Strip ½” of the insulation on the end of each wire.

5. Insert the wire cable from the thermostat thru the 9/16”

hole into the control box and place the thermostat wire

cable next to the low voltage pigtails. Secure the

thermostat wire cable with a strain relief to prevent

wire connections from being pulled apart.

6. Connect the Red (24 VAC) supply wire from the

thermostat to the Red low voltage pigtail wire on the

air handler. Fasten the wires together securely with a

wire nut. If the outdoor unit has a red wire or “R”

terminal then connect the red wire from the outdoor

unit with the Red thermostat wire from the second

cable and connect this red wire to the “RC” terminal on

the thermostat. Fasten the wires together securely with

a wire nut.

7. Connect the White (first stage heating) wire from the

thermostat to the White low voltage pigtail wire on the

air handler and the White wire from the “E” terminal

on the outdoor unit. Fasten the three wires together

securely with a wire nut.

8. Connect the Green (indoor fan) wire from the

thermostat to the Green low voltage pigtail wire on the

air handler and securely fasten the two wires together

with a wire nut.

9. Connect the Red wire from the “Y” terminal on the

outdoor unit. Fasten the three wires together securely

with a wire nut.

10. Connect the brown (24 VAC Common) wire from the

thermostat with the yellow low voltage pigtail wire on

the air handler and with the brown (Common) wire

from the “C” terminal on the outdoor unit. Fasten the

three wires together securely with a wire nut.

11. Connect the Orange (Reversing Valve Solenoid) wire

from the thermostat with the Orange wire from the “O”

terminal on the condenser unit. Fasten the two wires

together securely with a wire nut.

CONSTANT TORQUE MOTOR

Selecting the Constant Torque Blower Speed

This furnace uses the new constant torque high efficiency

motor. This motor operates on 240 VAC. The motor speed tap

are 24 VAC, 0.03 amps, 60 Hz, 1 PH. The speed taps can be

changed by removing the black wire from the blower motor

terminal T5 or the red wire from the blower motor terminal T1

and connecting the wires to T4, T3 or the T2 blower motor

terminals. Table 35 shows the constant torque motor terminals

and the connection definitions.

Terminal Connection

C Speed Tap Common - 24 VAC Common

L Supply Voltage - 240 Vac Line 1

G Ground Connection

N/L2 Supply Voltage - 240 Vac Line 2

1 Low Speed Tap - 24 VAC Input

2 Medium-Low Speed Tap - 24 VAC Input

3 Medium Speed Tap - 24 VAC Input

4 Medium-High Speed Tap - 24 VAC Input

5 High Speed Tap - 24 VAC Input

Table 35: Constant Torque Motor Terminals

Total 24 VAC circuit amps are 0.14 amps.

To avoid personal injury or property damage, make

certain that the motor leads cannot come into

contact with non-insulated metal components of

the unit.

Loading...

Loading...