MORTEXPRODUCTSINC.501TERMINALRDFORTWORTH,TEXAS76106 Page7

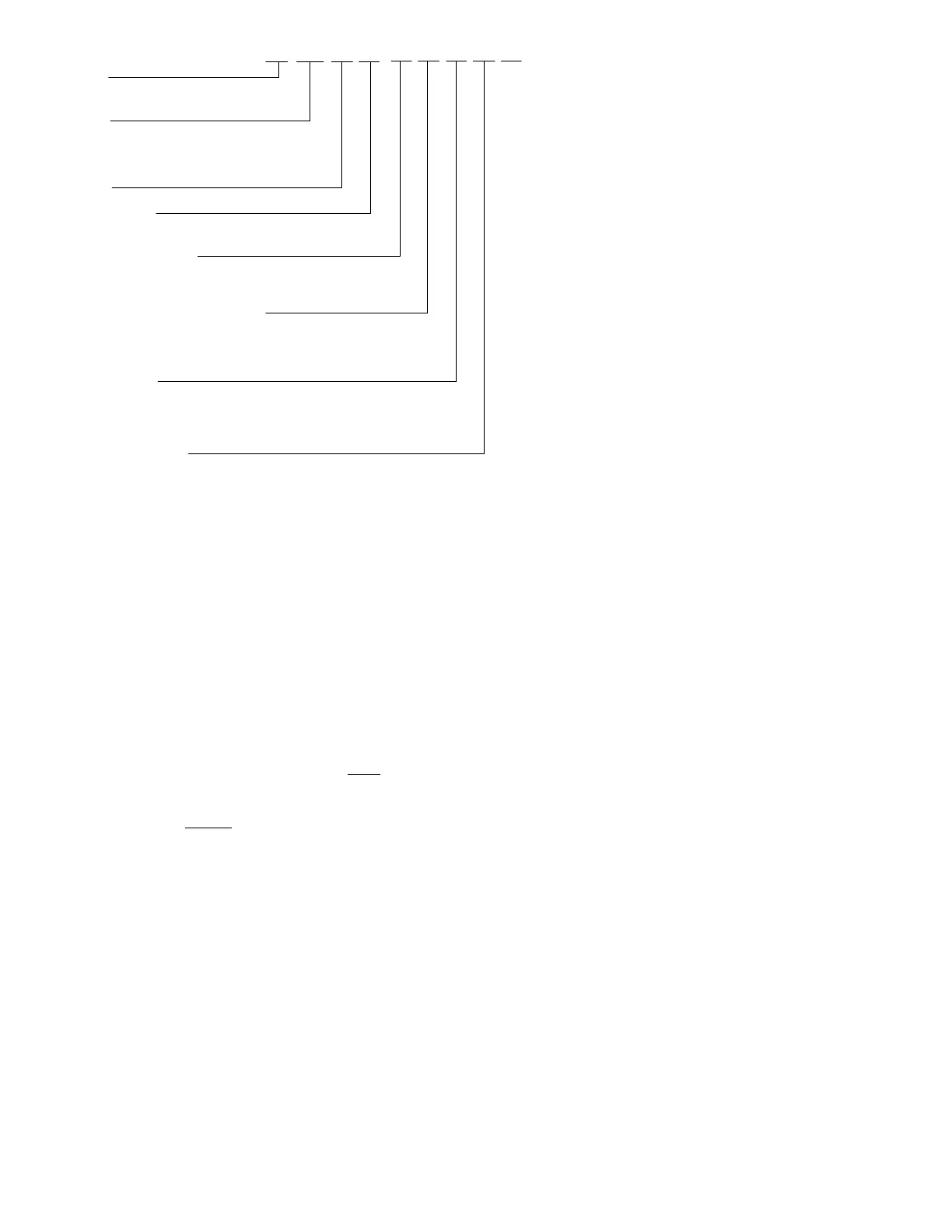

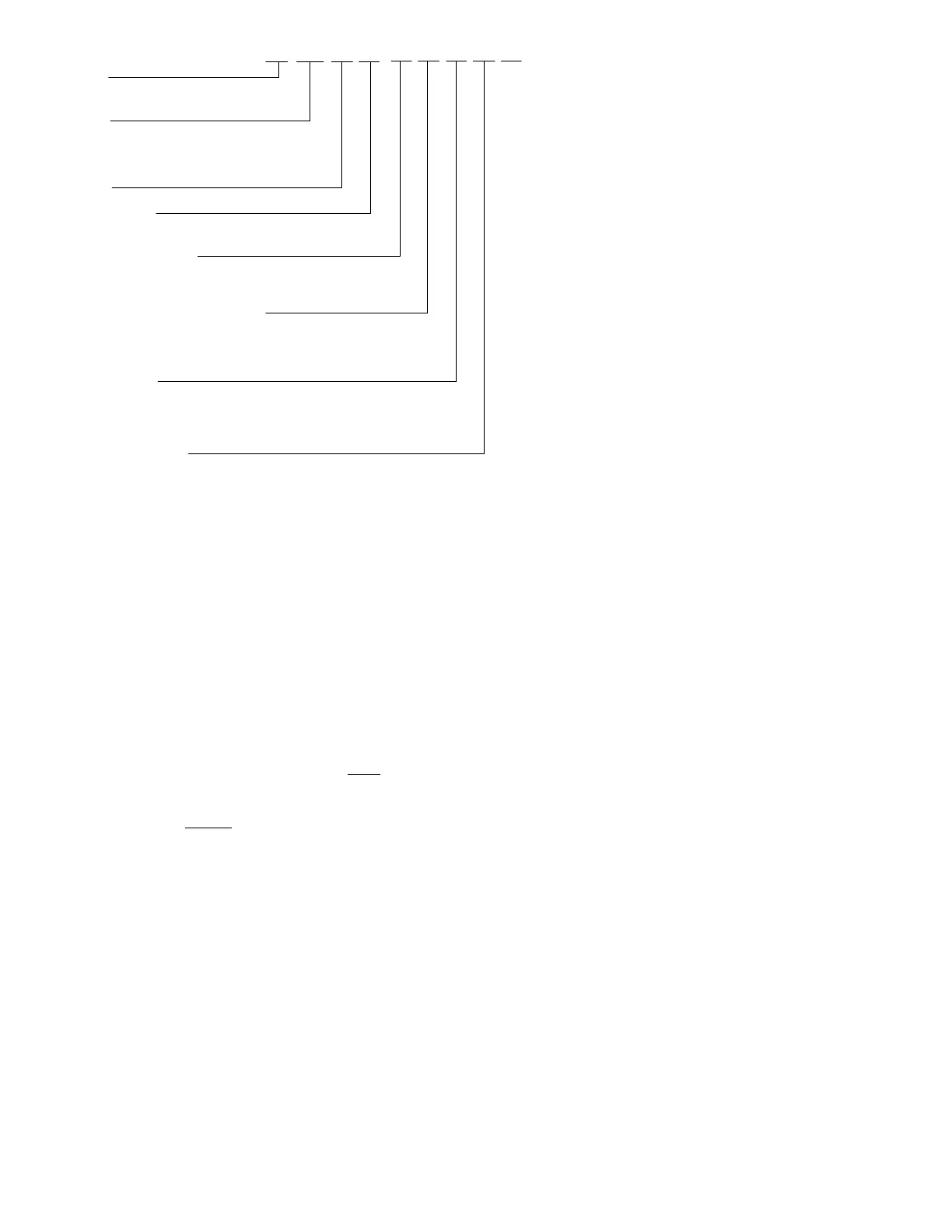

EHXS

2 4

0 3

ED1

C

79

SERIES

S - Horizontal Firdown Unit Uncased

C - Horizontal Firdown Unit Cased

TYPE

EHX - DX Coil and Electric Heat

CWE - Chilled Water Coil and Electric Heat

DXW - DX Coil and Hot Water Heat

CWW - Chilled Water Coil and Hot Water Heat

Tons

Nominal Cooling BTUH

Heating Capacity

03 - Electric Heat Capacity in kW

26 - Hot Water Heat Capacity in M/BTUH

Orifice or Expansion Valve Number

D - TXV4-A (E410A 1.5 to 2.5 Ton)

Y - TXV4-A (R410A 3.0 Ton)

Expansion Device Code

E = Expansion Valve (DX)

Time Delay Relay

1 - With TDR (Standard)

Unit Voltage

A - 115/1/60

C - 208/240/1/60

Motor & Wheel Code

65 - 1/4 HP, 208/240V, PSC, with (2) 6.25x8.00

70 - 1/4 HP, 115V, PSC, with (2) 6.25x8.00

78 - 1/4 HP, 115V, PSC, with (2) 6.25x6.88

79 - 1/4 HP, 240V, PSC, with (2) 6.25x6.88

80 - 1/3 HP, 208/230V, CT, with (2) 7.00x8.00

81 - 1/2 HP, 208/240V,CT, with (2) 7.00x9.00

82 - 1/3 HP, 115V,CT, with (2) 7.00x8.00

83 - 1/2 HP, 115V,CT, with (2) 7.00x9.00

2 = 2 Pipe Chilled Water (CW)

4 = 4 Pipe Chilled Water (CW)

4 - 4 Row Chilled Water Coil (CW)

5 - 5 Row Chilled Water Coil (CW)

Table 11: SEHX/CEHX/SCWE/CCWE/SDXW/CDXW/SCWW/CCWW Model Nomenclature

SECTION IlI: CLEARANCE AND RETURN

AIR REQUIREMENTS

LOCATION

Access for servicing is an important factor in the location of any

Air Handler unit. Provide a minimum of 27 inches under the

appliance for access to the control box, heating elements, water

pump, blower and air filters. The unit can be serviced entirely

from the bottom of the unit, including replacing the air filter on

models that include a filter rack. These units are NOT

designed

to be installed in a closet or flush mounted in a wall in an up

flow vertical position. The Air Handler unit is designed for

horizontal application ONLY.

Be sure to route primary and secondary drain connections

so as not to obstruct replacement filter.

Location is usually predetermined. Check with owner’s or

dealer’s installation plans. If location has not been decided,

consider the following in choosing a suitable location.

1. Select a location with adequate structural support, space for

service access, clearance for return and supply duct

connections. Unit is designed to fit in a 12” high drop down

space (Furred-In Area).

2. Where normal operating sound levels may be objectionable

if the Air Handler is placed directly over or under some

rooms such as bedrooms, study, etc.

3. Caution should be taken to locate the Air Handler unit so

that supply and return air ducts can deliver an even air

distribution of supply and return air to and from the living

spaces.

4. Locate appliance where electrical supply wiring can be

easily routed to main electrical panel and where electrical

wiring will not be damaged. Supply power wiring may be

installed in a flexible conduit or armored cable. The

installer must refer to National Electrical Code (NFPA 70),

Canadian Electrical Code, Part I (CSA C22.2), ANSI/NFPA

No. 70 and/or any local codes to ensure supply wiring

complies with all applicable codes for the location the

Horizontal Air Handler is being installed.

5. Locate appliance where thermostat wiring can be easily

routed to the thermostat and where the wiring will not be

damaged. Be sure wire has enough length so it will not to

block access to any components that may need to be

replaced or serviced.

6. Locate appliance where refrigerant lines can be easily

routed from the evaporator coil to the condenser.

7. When the coil is installed in a blow-thru application it will

create a positive pressure situation in the condensate drain

system. To prevent condensate from being blown out of the

condensate drain, it is recommended an anti-siphon air vent

be installed as shown in figure 16. This will allow proper

draining of the primary (Main) and secondary (Overflow)

drain lines. Refer to CONDENSATE DRAIN SYSTEM

and Figure 16 in these instructions.

NOTE: The condensate drain trap is not required on a

blow-thru system providing the drain pipe is not connected

to a sewer line.

NOTE: The condensate trap may be required by local

codes.

If the secondary drain is not used, it must be capped.

8. The blow-thru design will cause exterior surface of cabinet

to sweat when units is installed in a non-conditioned space

such as an attic or garage. Installer must provide protection

Loading...

Loading...