MORTEXPRODUCTSINC.501TERMINALRDFORTWORTH,TEXAS76106 Page15

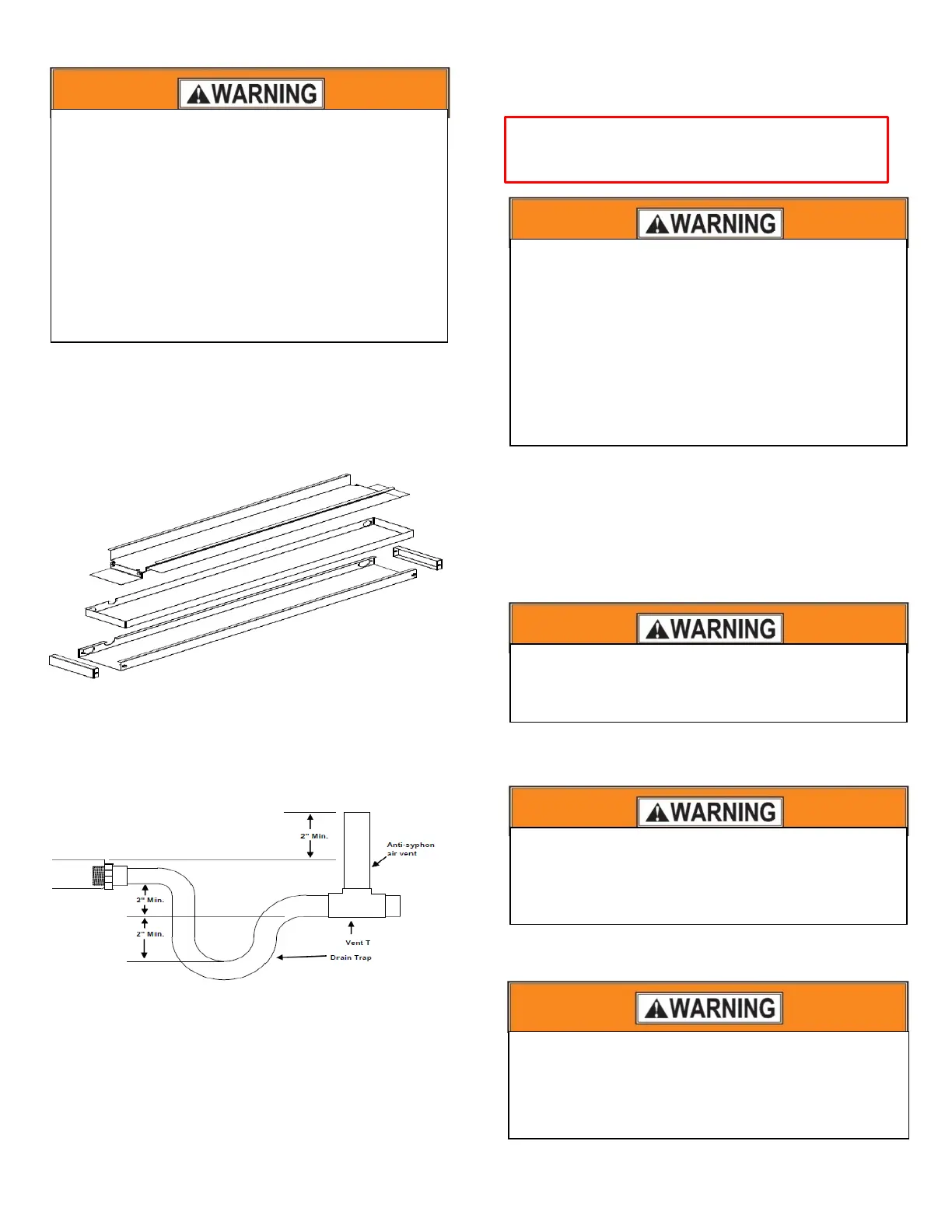

CONDENSATE DRAIN PIPING:

The horizontal Air Handler cooling DX coil condensate drain

pan has one ¾” NPT female primary and one ¾” NPT female

secondary connection is on the same side as the refrigerant

connections. The other side of the condensate drain pan is one

¾” NPT female primary drain connection and no secondary

drain connections. Refer to figure 15 for drain locations.

Figure 15: Condensate Drain Pan

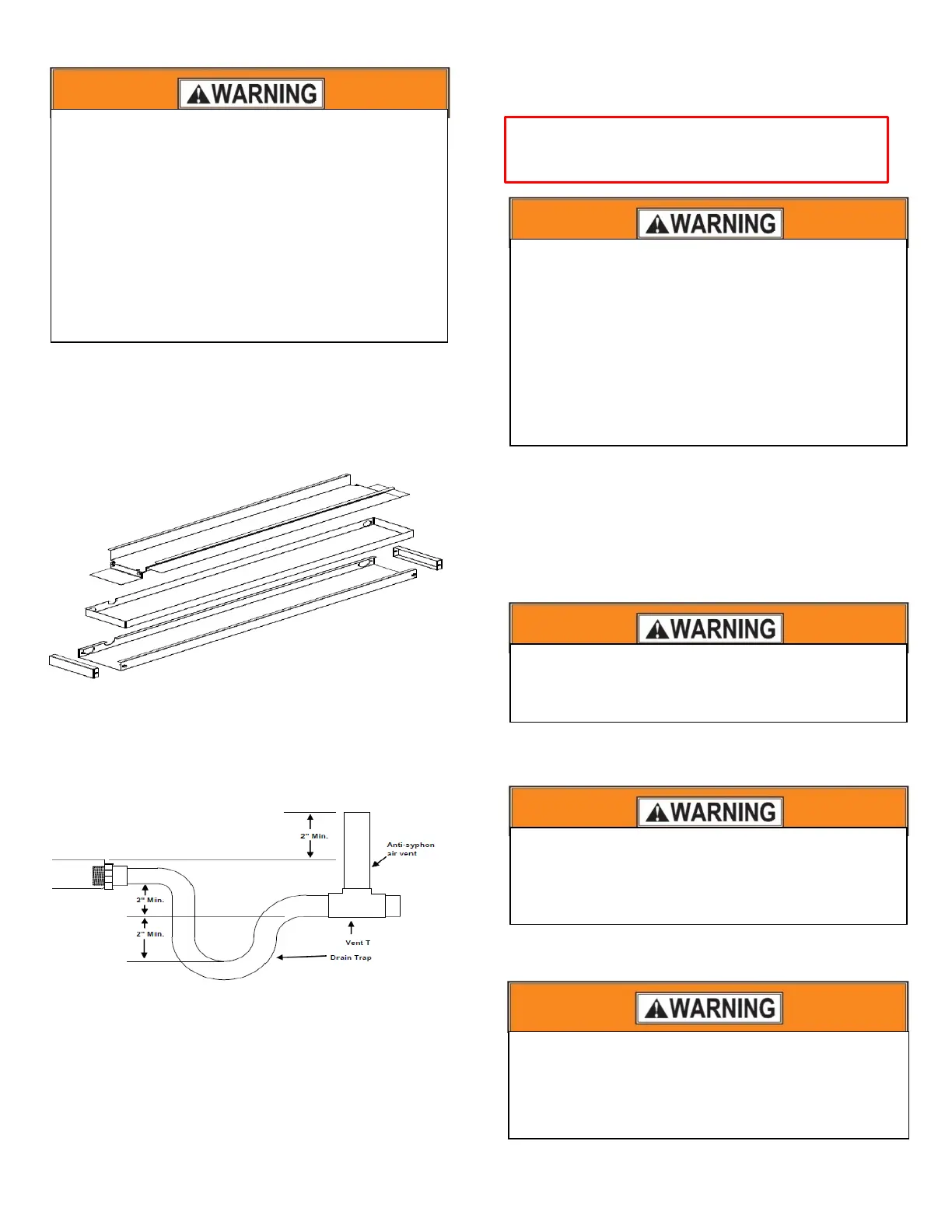

Piping from each fitting used is to have 1-1/2 minimum trap and

each run in such a manner as to provide enough slope for

adequate drainage to a visible area. Do not pipe these two

fittings together into a common drain. Cap unused connection.

Figure 16: Typical Condensate Traps

SECTION VII: HOT AND CHILLER WATER

Water Piping

All piping must be supported independent of coils to prevent

vibration and stress on coil headers. Swing joints or flexible

fittings must be provided to absorb expansion and contraction

strains. Rigid piping reduces the effectiveness of vibration

isolators. Coil water pipes must be adequately vented in order to

prevent air binding. Units are provided with manual air vents

mounted on coil manifold.

"Massachusetts requires an electronically controlled

pump timer that activates the pump every 6 hours

water heater and the air handler to 50 feet max."

for 60 seconds and limits the distance between the

Total hot water piping should not exceed 140 feet. All hot water

piping to the coil should be 3/4 inch ID (7/8 inch OD) copper.

CPVC piping may be used in applications where the water

temperature does not exceed 150°F. It is recommended a water

isolation valve and a union be placed in the water lines to and

from the coil, near the coil, for serviceability, repair or

replacement of the coil.

After piping has been installed, allow the system to fill with

water and check connections for leaks. To insure complete

filling of the system, follow start-up procedure.

A thermal expansion tank is recommended on any closed loop

system to relieve thermal expansion due to pressure increase.

Horizontal Air Handler Unit must be located so that if any

connections should leak, water will not cause damage to

the adjacent area.

When such locations can’t be avoided, a suitable drain pan

should be installed under the air handler, not over 1-1/2”

deep, with minimum length and width at least 2” greater

than the air handler dimensions and connected to an

adequate drain.

Under no circumstances is the manufacturer to be held

liable for any water damage in connection with this

Horizontal Air Handler Unit.

Horizontal Air Handler Unit must be located so that if any

connections should leak, water will not cause damage to

the adjacent area.

When such locations can’t be avoided, a suitable drain pan

should be installed under the air handler, not over 1-1/2”

deep, with minimum length and width at least 2” greater

than the air handler dimensions and connected to an

adequate drain.

Under no circumstances is the manufacturer to be held

liable for any water damage in connection with this

horizontal Air Handle

unit.

Toxic chemicals used for treatment of boilers or non-

potable water heating appliances shall never be introduced

into a potable water space heating system.

When system requires water at temperatures higher than

required for other uses, a means such as a mixing valve

shall be installed to temper the water for those uses in order

to reduce the scald hazard potential.

Hot water from a boiler used to satisfy heating requirements

can be heated to temperatures of 180°F. Parts containing

water this hot can scald very quickly. Use extreme caution

when servicing or performing maintenance on any parts

containing hot water.

Loading...

Loading...