ARES-G2 Getting Started Guide Page 39

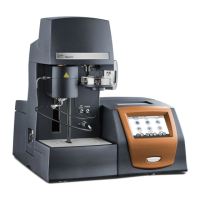

Inspecting the System

When you receive your ARES-G2, look over the instrument and shipping container carefully for signs of

shipping damage, and check the parts received against the enclosed shipping list.

• If the instrument is damaged, notify the carrier and TA Instruments immediately.

• If the instrument is intact but parts are missing, contact TA Instruments.

Choosing a Location

It is important to choose a location for the instrument using the following guidelines. The ARES-G2

should be:

In

• A temperature- and humidity-controlled area. Temperatures should be in range of 20°C to 30°C.

• A clean, vibration-free environment, preferably on the ground floor in the building. It should be

located away from pumps, motors, or other devices which produce vibrations.

• An area with ample working and ventilation space.

• An area that allows at least six inches of clearance on all sides of the equipment, and that allows a min-

imum of eight inches from the open and closed positions of all heated environment control systems.

• An area that does not restrict airflow to cooling fans on the rear of the power control box, or the option

controllers.

On

• A stable work surface. A marble table is recommended. Isolation mounts on a standard lab bench are

not recommended.

Near

• A power outlet. An ARES-G2 without an oven, requires from 90 to 264 VAC/ 50 or 60Hz with a 15

amp outlet. Any unit with an oven requires 180 to 264 VAC / 50 or 60Hz with a 20 amp outlet.

• Your TA Instruments TRIOS controller.

• Compressed lab air and purge gas supplies with suitable regulators and filters.

Away from

• Dusty environments.

• Exposure to direct sunlight.

• Direct air drafts (fans, room air ducts).

• Poorly ventilated areas.

• Noisy or mechanical vibrations.

• High traffic areas, where constant movements from passing personnel could create air currents or

mechanical disturbances.

Loading...

Loading...