Taco® SKV

57

302-365, Effective: June 5, 2017

© 2017 Taco, Inc.

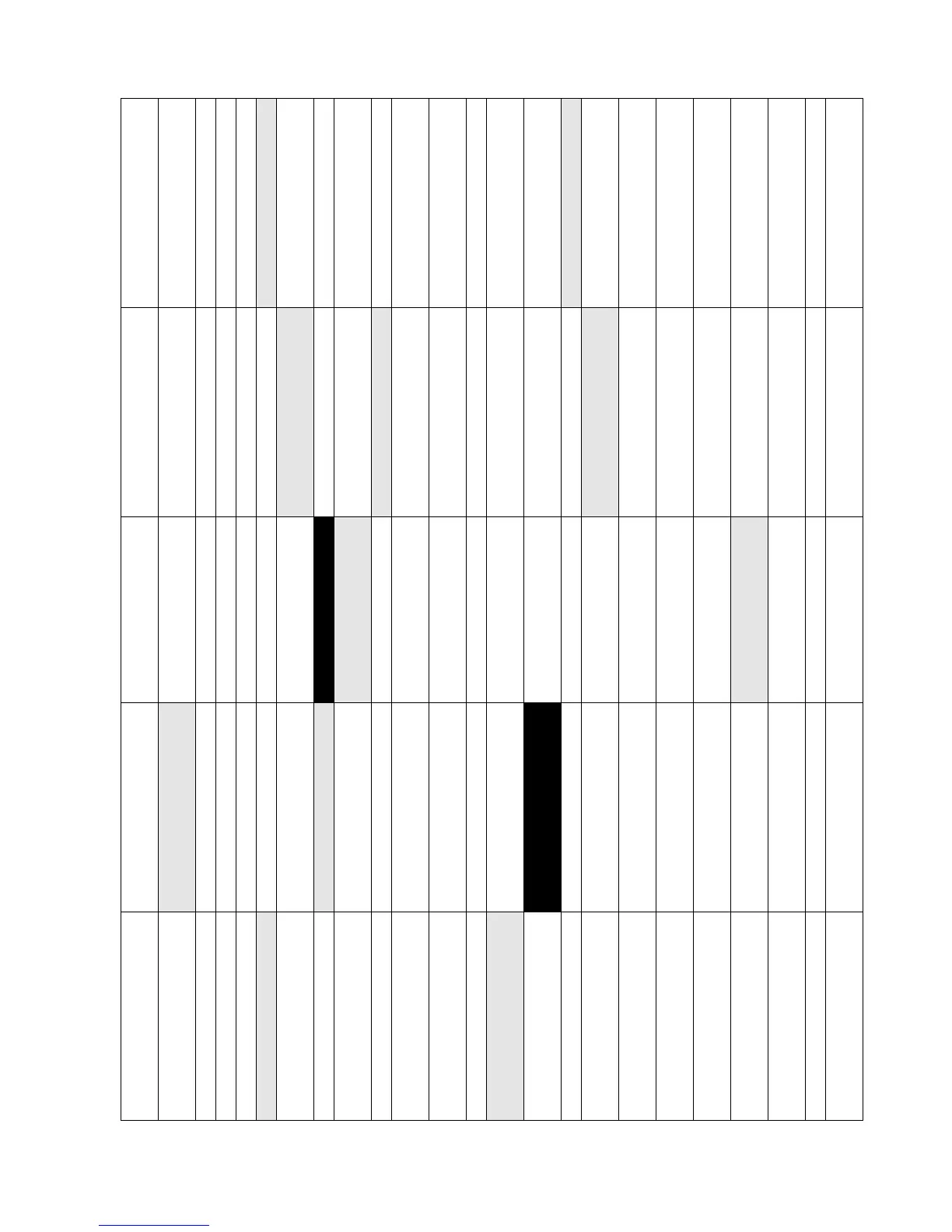

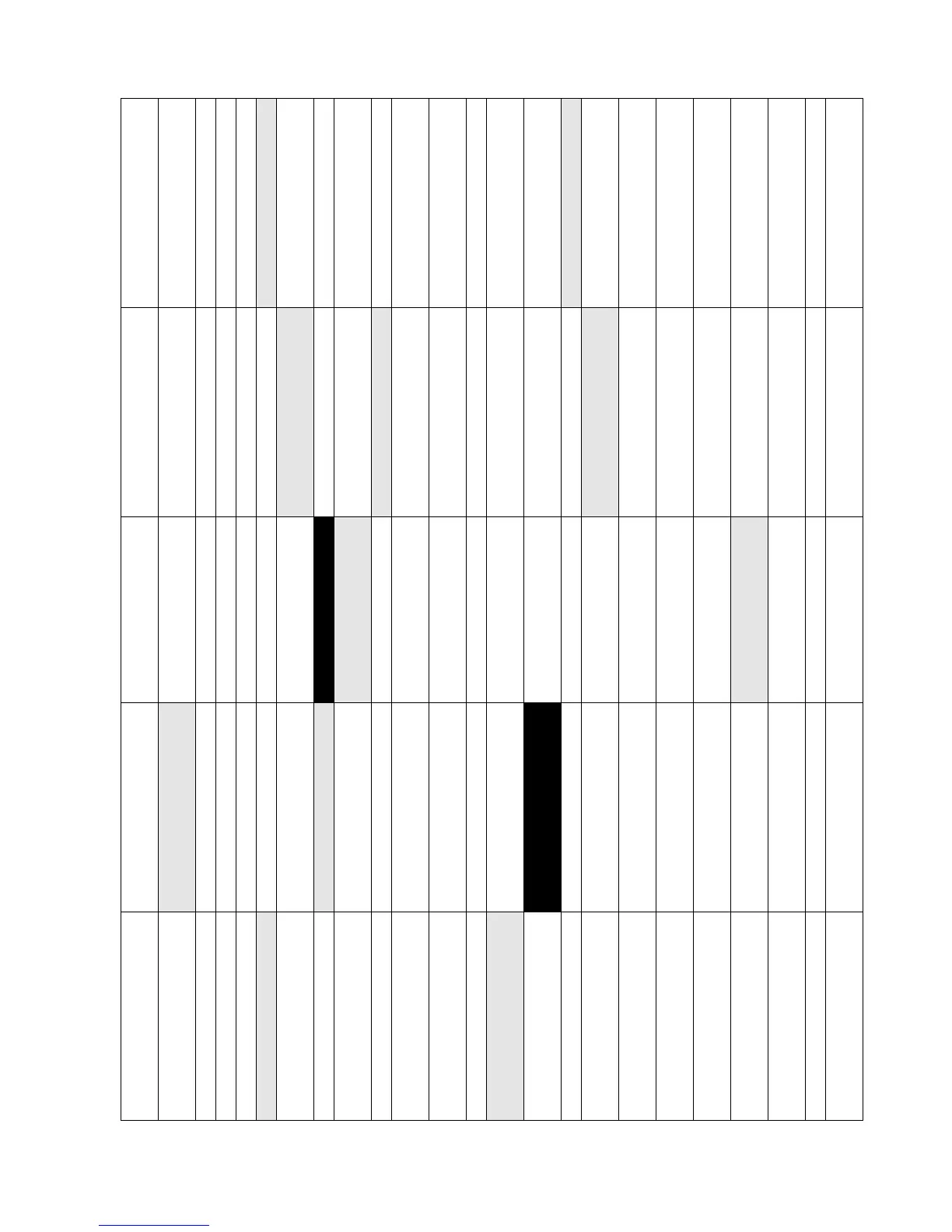

13.0.8 Main Menu Structure - page 6

16-38 SL Controller State 16-77 Analog Out X30/8 [mA] 18-35 Analog Out X42/11 [V] 20-33 User-defined Refrigerant

A3

21-01 PID Performance

16-39 Control Card Temp.

16-8* Fieldbus & FC Port 18-36 Analog Input X48/2

[mA]

20-34 Duct 1 Area [m2] 21-02 PID Output Change

16-40 Logging Buffer Full 16-80 Fieldbus CTW 1 18-37 Temp. Input X48/4 20-35 Duct 1 Area [in2] 21-03 Minimum Feedback Level

16-43 Timed Actions Status 16-82 Fieldbus REF 1 18-38 Temp. Input X48/7 20-36 Duct 2 Area [m2] 21-04 Maximum Feedback Level

16-49 Current Fault Source 16-84 Comm. Option STW 18-39 Temp. Input X48/10 20-37 Duct 2 Area [in2] 21-09 PID Autotuning

16-5* Ref. & Feedb. 16-85 FC Port CTW 1 18-5* Ref. & Feedb. 20-38 Air Density Factor [%] 21-1* Ext. CL 1 Ref./Fb.

16-50 External Reference 16-86 FC Port REF 1 18-50 Sensorless Readout

[unit]

20-6* Sensorless 21-10 Ext. 1 Ref./Feedback Unit

16-52 Feedback [Unit]

16-9* Diagnosis Readouts 20-** Drive Closed-loop 20-60 Sensorless Unit 21-11 Ext. 1 Minimum Reference

16-53 Digi Pot Reference 16-90 Alarm Word

20-0* Feedback 20-69 Sensorless Information 21-12 Ext. 1 Maximum Refer-

ence

16-54 Feedback 1 [Unit] 2 16-91 Alarm Word 20-00 Feedback 1 Source

20-7* PID Autotuning 21-13 Ext. 1 Reference Source

16-55 Feedback 2 [Unit] 16-92 Warning Word 20-01 Feedback 1 Conver-

sion

20-70 Closed-loop Type 21-14 Ext. 1 Feedback Source

16-56 Feedback 3 [Unit] 16-93 Warning Word 2 20-02 Feedback 1 Source

Unit

20-71 PID Performance 21-15 Ext. 1 Setpoint

16-58 PID Output [%] 16-94 Ext. Status Word 20-03 Feedback 2 Source 20-72 PID Output Change 21-17 Ext. 1 Reference [Unit]

16-6* Inputs & Outputs 16-96 Maintenance Word 20-04 Feedback 2 Conver-

sion

20-73 Minimum Feedback Level 21-18 Ext. 1 Feedback [Unit]

16-60 Digital Input

18-** Info & Readouts 20-05 Feedback 2 Source

Unit

20-74 Maximum Feedback Level 21-19 Ext. 1 Output [%]

16-61 Terminal 53 Switch Setting 18-0* Maintenance Log 20-06 Feedback 3 Source 20-79 PID Autotuning

21-2* Ext. CL 1 PID

16-62 Analog Input 53 18-00 Maintenance Log: Item 20-07 Feedback 3 Conver-

sion

20-8* PID Basic Settings 21-20 Ext. 1 Normal/Inverse

Control

16-63 Terminal 54 Switch Setting 18-01 Maintenance Log: Action 20-08 Feedback 3 Source

Unit

20-81 PID Normal/ Inverse Con-

trol

21-21 Ext. 1 Proportional Gain

16-64 Analog Input 54 18-02 Maintenance Log: Time 20-12 Reference/Feedback

Unit

20-82 PID Start Speed [RPM] 21-22 Ext. 1 Integral Time

16-65 Analog Output 42 [mA] 18-03 Maintenance Log: Date

and Time

20-13 Minimum Reference/

Feedb.

20-83 PID Start Speed [Hz] 21-23 Ext. 1 Differentation Time

21-24 Ext. 1 Dif. Gain Limit 21-60 Ext. 3 Normal/Inverse

Control

22-4* Sleep Mode 22-86 Speed at Design Point

[Hz]

23-60 Trend Variable

21-3* Ext. CL 2 Ref./Fb. 21-61 Ext. 3 Proportional Gain 22-40 Minimum Run Time 22-87 Pressure at No-Flow

Speed

23-61 Continuous Bin Data

21-30 Ext. 2 Ref./Feedback Unit 21-62 Ext. 3 Integral Time 22-41 Minimum Sleep Time 22-88 Pressure at Rated Speed 23-62 Timed Bin Data

21-31 Ext. 2 Minimum Reference 21-63 Ext. 3 Differentation Time 22-42 Wake-up Speed

[RPM]

22-89 Flow at Design Point 23-63 Timed Period Start

Loading...

Loading...