M8SL2-00-002-812 Functional Testing F4.1

© Copyright Tait Electronics Limited August 2004. All rights reserved.

4 Functional Testing

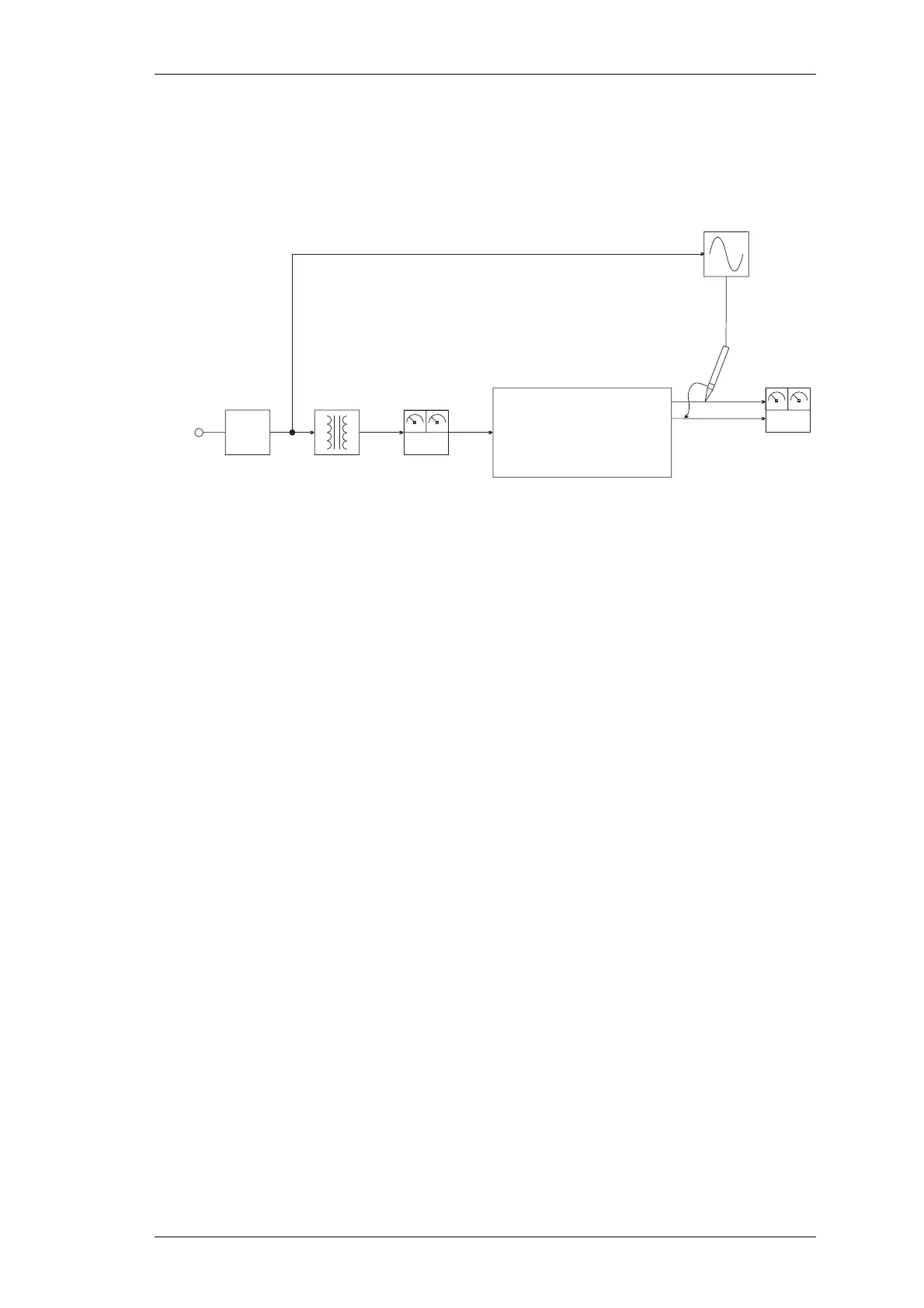

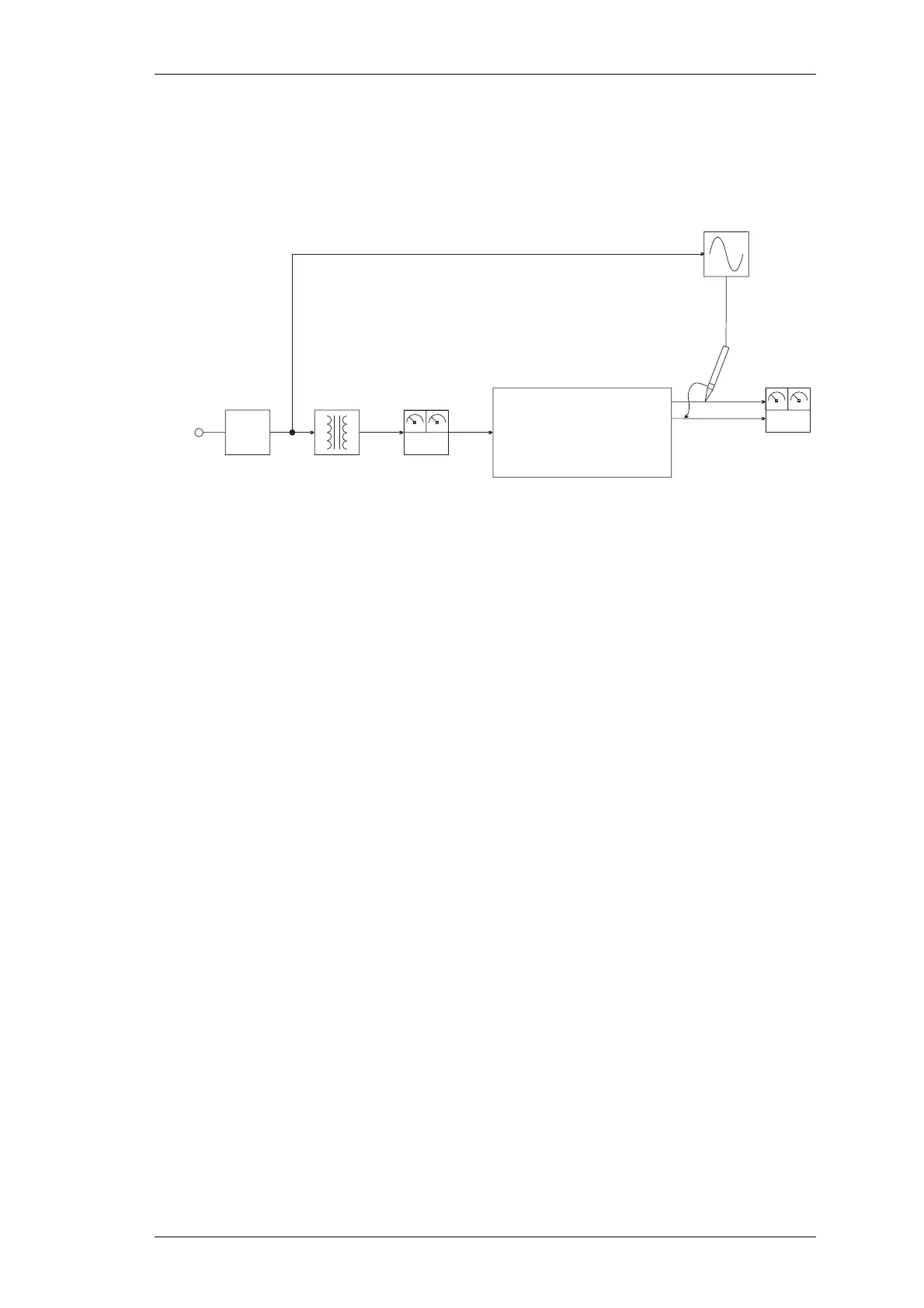

The following test procedures will confirm that the T800-23-0011 has been set up and

adjusted correctly and is fully operational. Refer to Figure 4.1 for test equipment details.

Figure 4.1 Test equipment setup

4.1 Basic Operation

To confirm the basic operation of the power supply, proceed as follows.

• Ensure that the main supply to the T800-23-0011 is switched off. Set up the

test equipment as shown in Figure 4.1.

• Set the output DC load to maximum resistance/minimum current.

• Connect the T800-23-0011 to the mains supply and switch it on.

• Vary the DC load and check that the output voltage and current are within

the specifications (refer to Section 1.2.4).

4.2 Output Current Overload

To confirm the operation of the current overload protection circuitry, proceed as follows.

• Ensure that the main supply to the T800-23-0011 is switched off. Set up the

test equipment as shown in Figure 4.1.

• Set the output DC load to draw approximately 11A.

• Switch on the mains supply and slowly decrease the load resistance, thereby

increasing the current until voltage foldback occurs. The current should not

rise above the Current Overload Limit (refer to Section 1.2.4), but voltage

should drop away.

Earth

Leakage

Circuit

Breaker

VA__

*

Mains

Supply

Isolating

Transformer

1kVA

Variac

0 to 260V

1kVA

AC

* True RMS Reading

T800-23-0011 PSU

+

-

AC

Input

Output

VA__

DC Load

0 to 30A

DC

Oscilloscope

Loading...

Loading...