OPERATING PROCEDURES

6-3

PH61 Peristaltic Pump

Operating Procedures

6

Figure 6-8

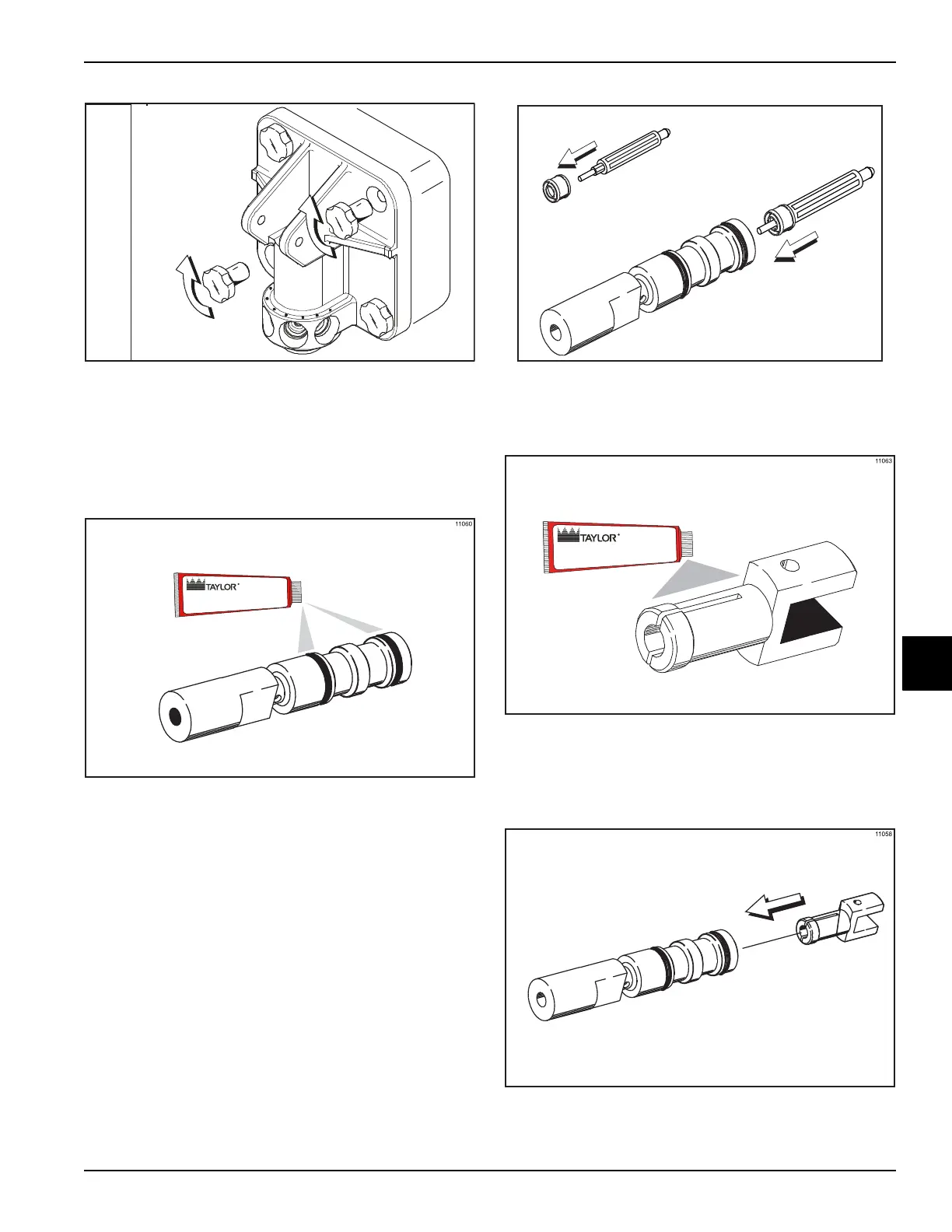

8. Assemble the draw-valve spinner assembly. Inspect

draw-valve O-rings for cuts or nicks. (Replace if cut

or nicked.) If draw-valve O-rings are in good

condition, slide the two O-rings into the grooves of

the draw valve and lubricate. (

See Figure 6-9.)

Figure 6-9

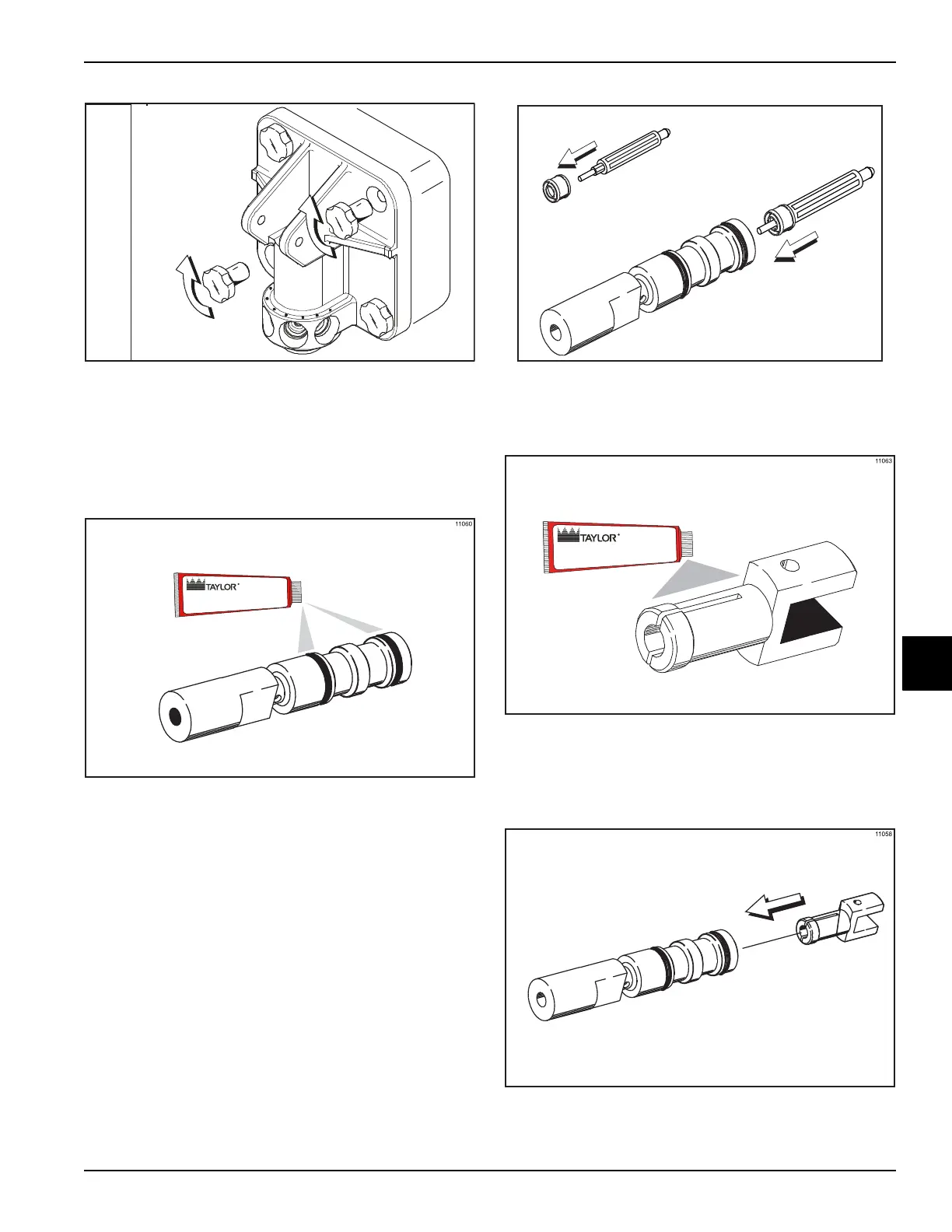

9. Lubricate the outer diameter of the spinner shaft seal.

Fill the cups on each end of the seal with lubricant.

Insert the spinner shaft seal into the bottom of the

draw valve as far as it will go. The spinner shaft seal

should fit into the seal groove inside the draw valve

cavity.

Important! Inspect to see that the spinner shaft seal

is correctly installed in the groove. A worn, missing,

or improperly installed spinner shaft seal will cause

product leakage out the top of the draw valve. (See

Figure 6-10.)

Figure 6-10

10. Lubricate the smaller end of the driven spinner.

(See Figure 6-11.)

Figure 6-11

11. Squeezing the split end together, insert the driven

spinner through the metal opening of the draw valve

until it snaps into place. (

See Figure 6-12.)

Figure 6-12

Apply the appropriate

Taylor approved food safe lubricant.

HP

Apply the appropriate

Taylor approved food safe lubricant.

HP

Loading...

Loading...