TMP4100-Series Installation/Maintenance

33480D01.DOC 1-9

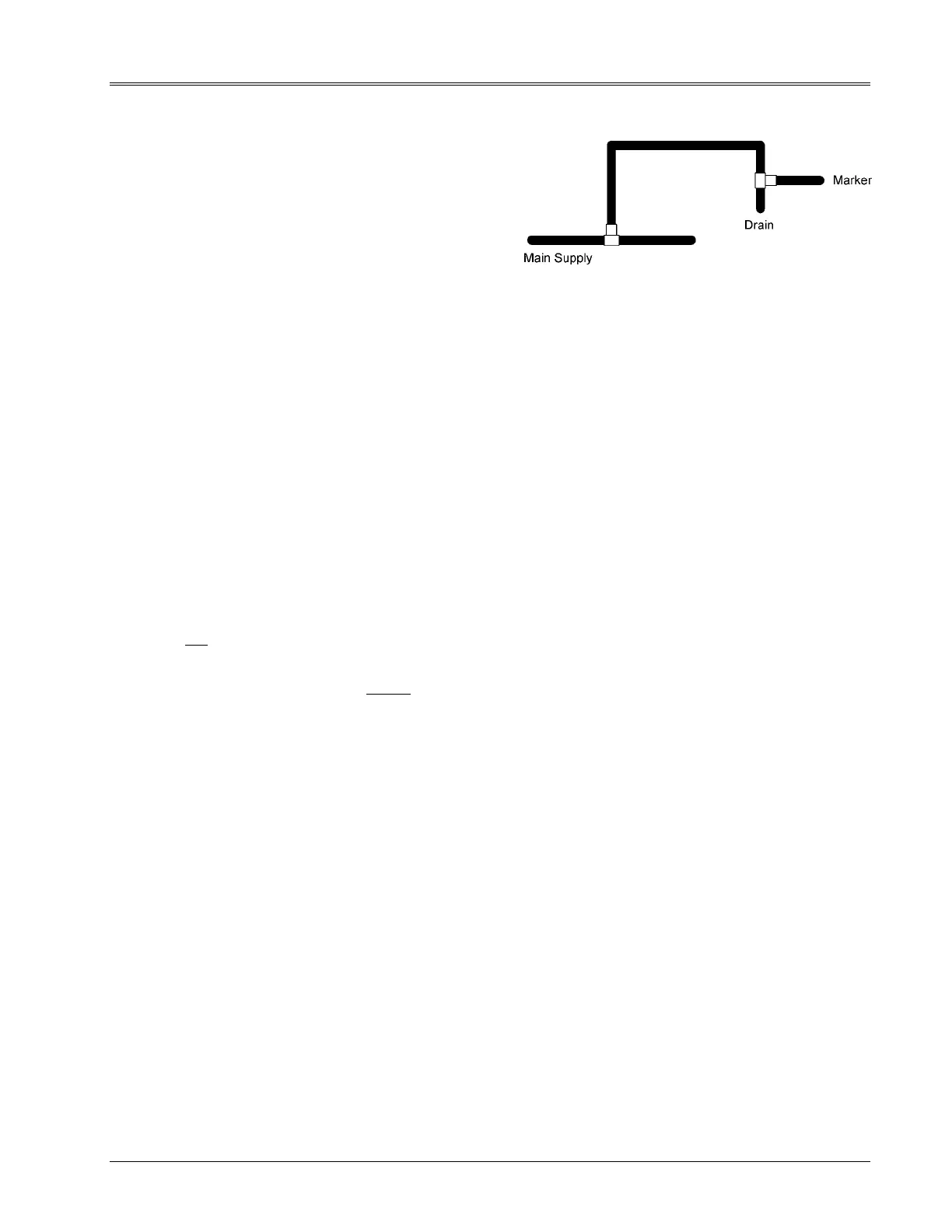

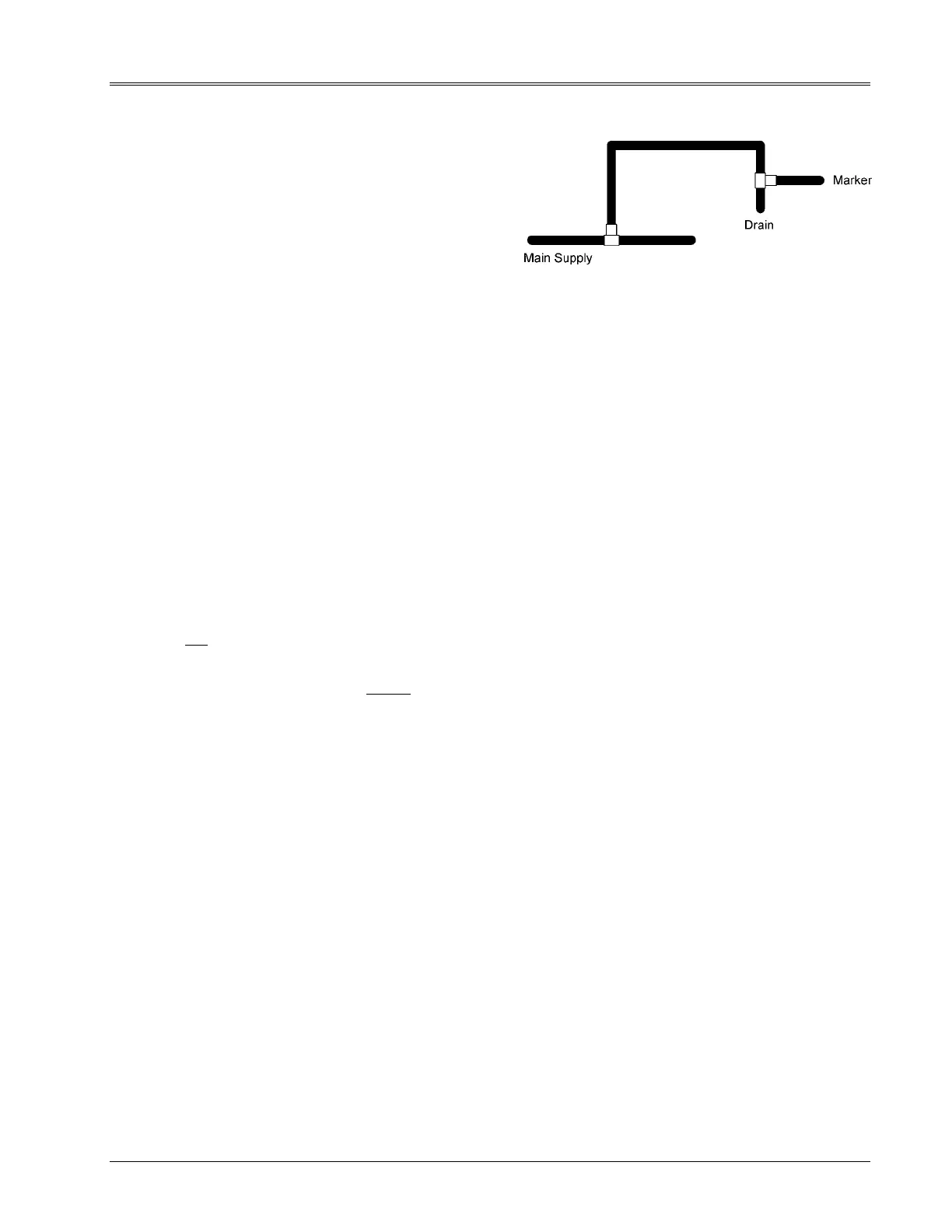

Plumbing Factors. Another practice for obtaining clean,

dry air is to ensure the equipment is not at the end of the

air line. Plumb the air supply to go up (vertically) off the

main air supply line, then down to the top of a tee. The

stem of the tee should be horizontal and go to the

marker. The bottom of the tee should be a short stub with

a drain valve or drip leg.

Parameters. The following parameters are easily achievable with a pre-filter and most coalescing filters.

• Humidity non-condensing

• 99.97% of the sub-micron particles removed

• 0.75 micron largest aerosol particle

• 0.30 micron largest solid particle

• 40° to 120°F (4.4° to 48.9°C)

• 5 micron pre-filter with an auto drain.

Practices. Follow these practices when installing and operating the marker to improve the quality of the air

and increase the reliability of your marking equipment.

• Install the filter as close as possible to the marking head, never more than 50 ft. (15 m)

• Use Polyflo® tubing downstream of filter with brass or plated fittings

• Use copper, brass or stainless tubing upstream of the filter

• Do not

use iron pipe or iron fittings.

• Do not use Teflon

®

tape

• Liquid Teflon

®

is permissible except:

– on poly-carbonate plastic threaded holes

– on the first thread of male fittings

• Blow down the air system after installation and before use (at least two minutes at full flow).

• Use a top tap off the main line with a drip leg (see Plumbing Factors).

• Do not use poly-carbonate bowls (they will crack when used with synthetic oils).

• Always use the largest available feed line and the shortest available run.

Loading...

Loading...