TMP4100-Series Installation/Maintenance

2-12 33480D01.DOC

2.7 REPAIR PROCEDURES

Authorized repair of the TMP4100-Series marking head is limited to impact pin reconditioning. Any other

repair of the marking head must be performed by repair agencies authorized by Telesis Technologies, Inc.

2.7.1 Impact Pin Reconditioning

Pin life depends largely on the type of material being marked, how hard or abrasive it is, and the required

marking depth. On typical metals with a hardness of Rockwell Rb47, marking at a depth of .127 mm

(0.005 in.), powdered steel pins average about 3 million impressions before needing sharpened.

Periodically, the tips of the impact pins will become dull and require reconditioning. Grind (or replace) the

impact pins on a regular basis to prevent dull pins from producing an unsatisfactory mark.

Pins should be reconditioned at the first sign of mark degradation or when the pin point becomes noticeably

flattened. The length of service between reconditioning will depend on the pin material, the material being

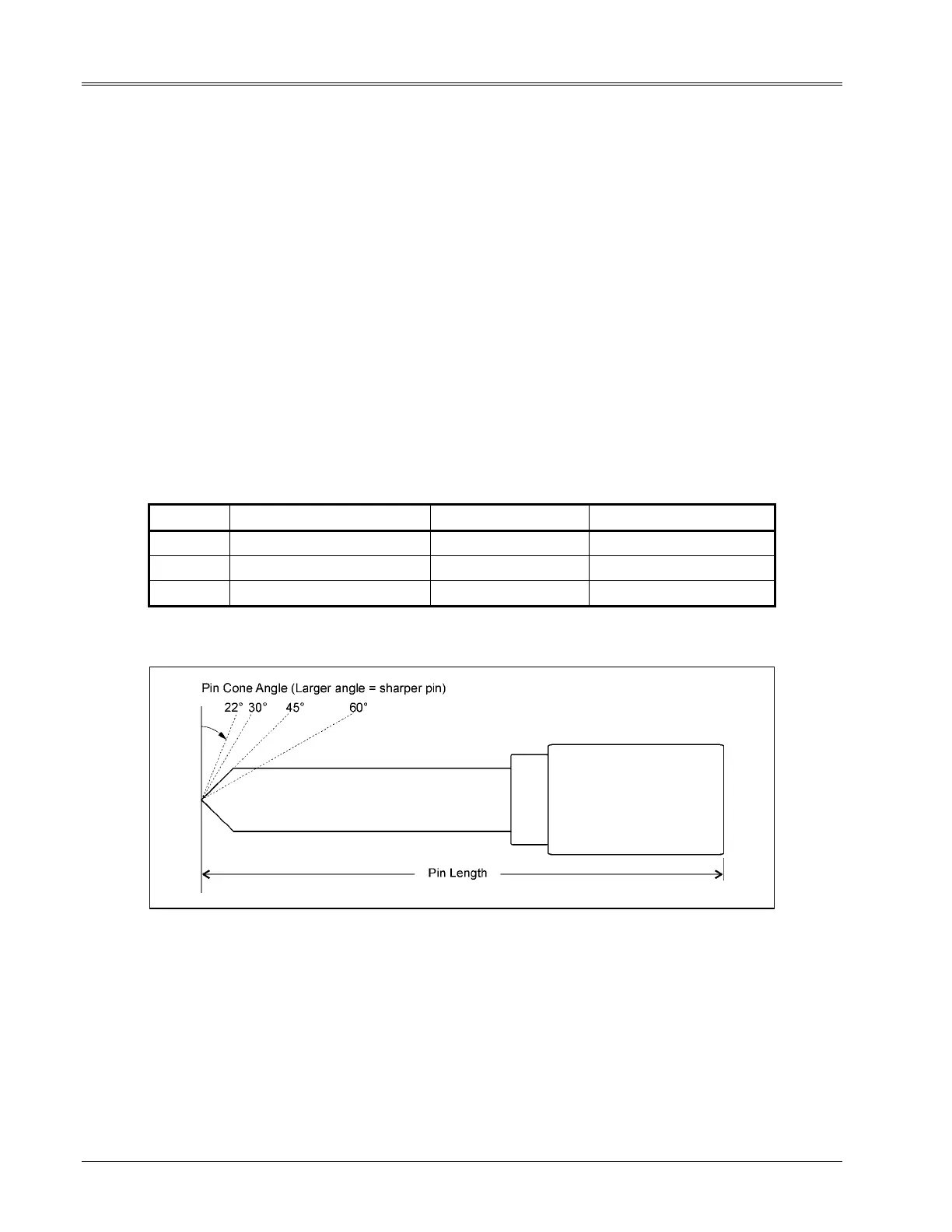

marked and the depth of the mark desired. Table 2-5 lists the lengths for new and reconditioned pins. The

pin cone angle and length are illustrated in Figure 2-2.

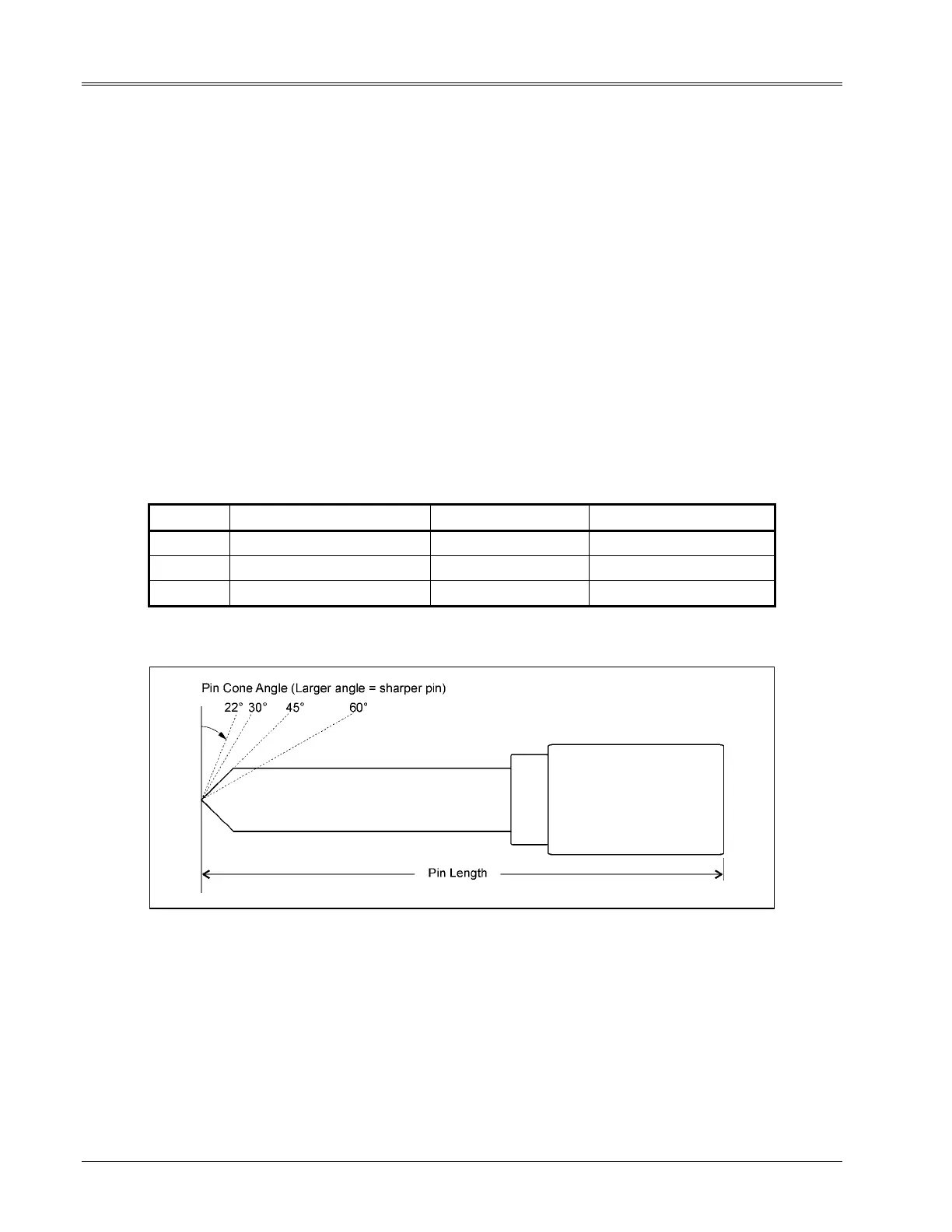

Table 2-5. Impact Pin Lengths

PIN TYPE MARKING HEAD NEW LENGTH MINIMUM LENGTH

25L TMP4100, TMP4150, TMP4155 2.18 in. (55.4 mm) 2.12 in. (53.8 mm)

150S TMP4100, TMP4150, TMP4155 2.75 in. (69.9 mm) 2.68 in. (68.1 mm)

25XLE TMP4100E only 1.77 in. (45.0 mm) 1.70 in. (43.2 mm)

Figure 2-2. Pin Cone Angle and Length

Loading...

Loading...