TMP4100-Series Installation/Maintenance

33480D01.DOC 2-9

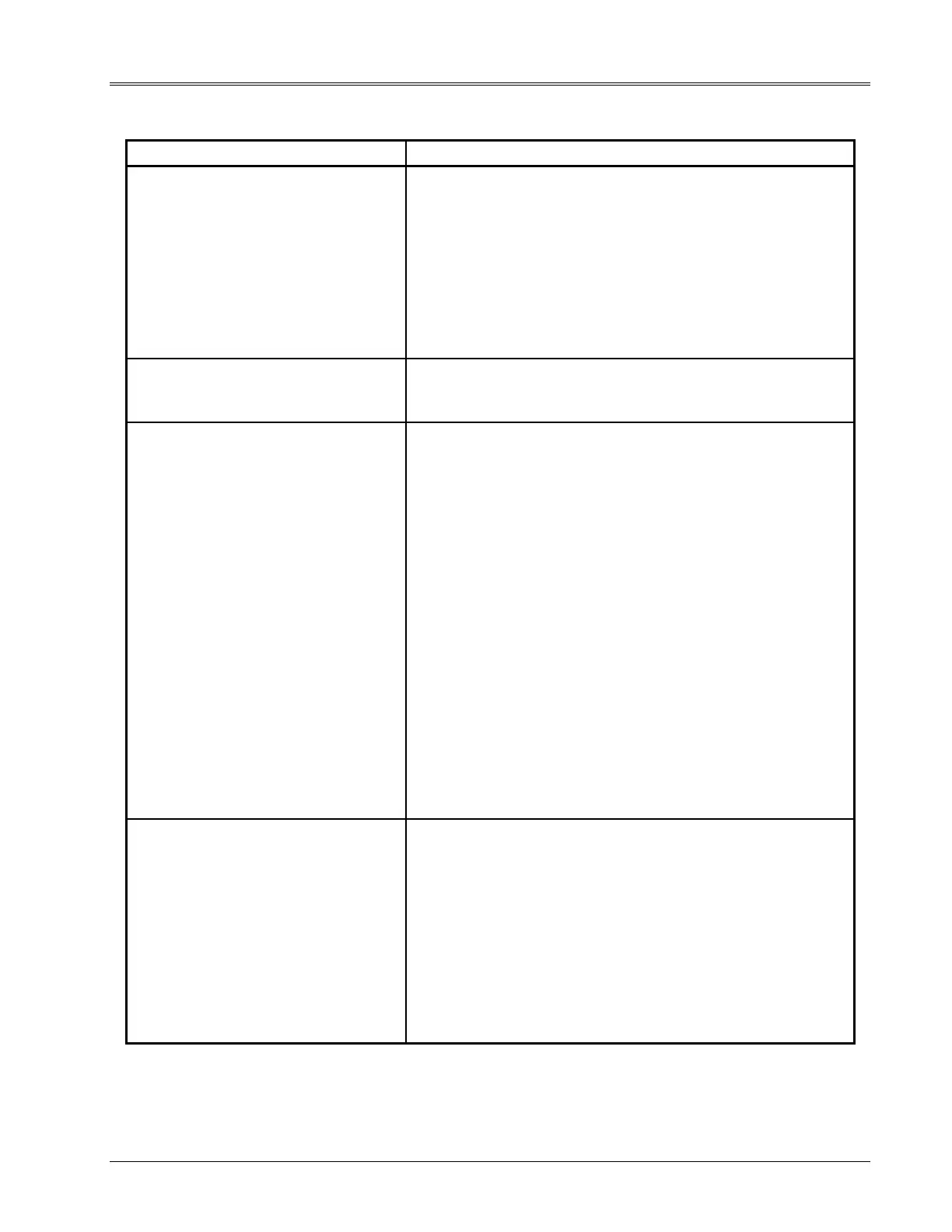

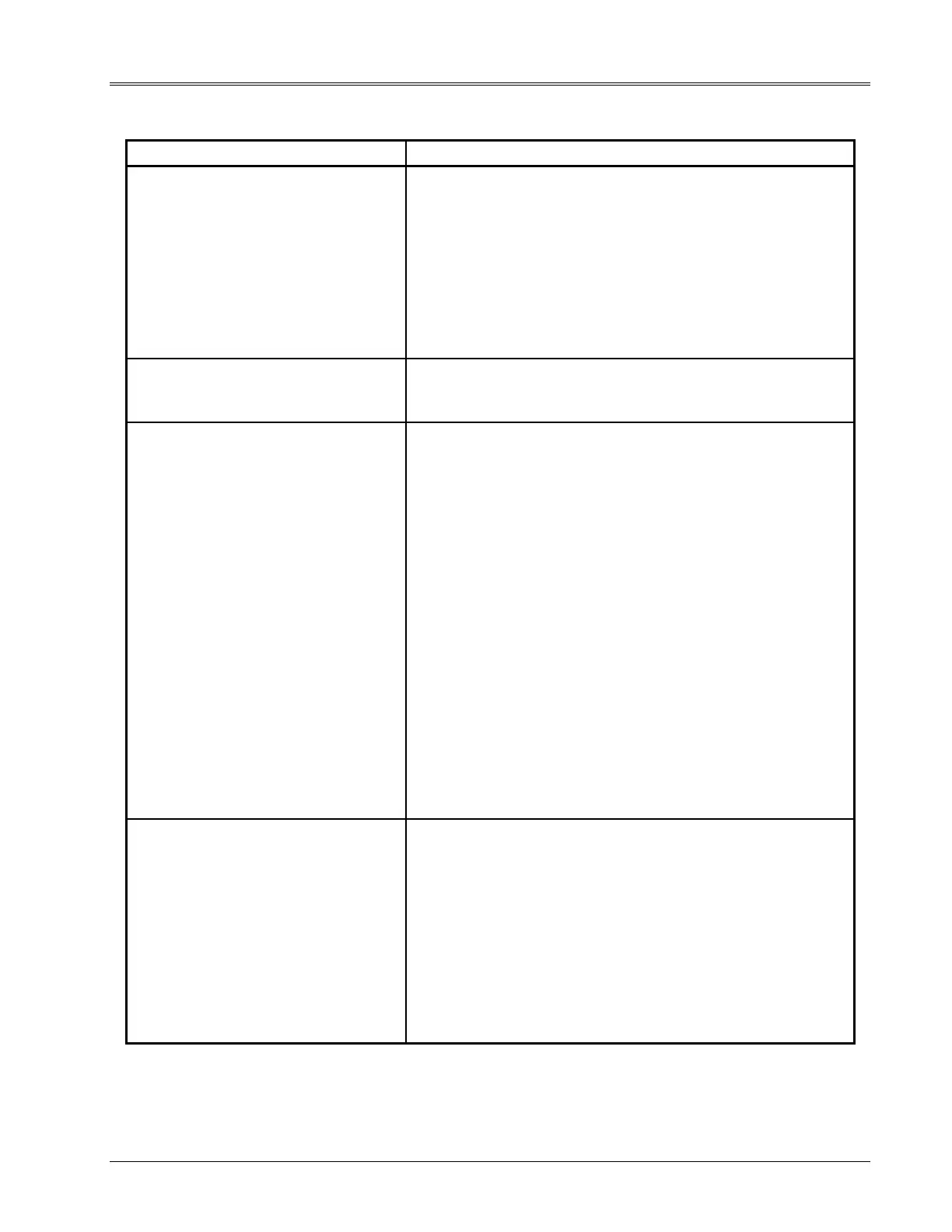

Table 2-1. Troubleshooting the Marking Head (continued)

PROBLEM CORRECTIVE ACTION

Indentation depth is inconsistent in a particular

area of the marking window.

1. TMP4100, TMP4150, TMP4155: The coiled Drive Air tubing may be

kinked or restricted when traversing. Inspect the tubing from the valve to

the manifold for cracks, restrictions or crimps in the tubing.

2. TMP4100, TMP4150, TMP4155: Loose or incorrectly mounted head

cartridge.. Check for a loose cartridge, leaking air, or a cartridge mounted

incorrectly.

3. TMP4100, TMP4150, TMP4155: Worn cartridge, or excessive dirt/oil in

the Drive Air making the pin stick. Inspect the pin cartridge for excessive

"blow by" air.

Remove the cartridge, push the pin into the cartridge, and release it in a

vertical position (pin down). The pin should drop freely. If not clean with

isopropyl alcohol and try again.

The indentations within the characters are not

placed accurately.

• The marker or material to be marked may be moving relative to each other

during the marking cycle. In order to assure a high quality mark, it is

important that there is little or no relative movement between the marker

and material being marked.

The marked characters are wholly or partially

garbled or skewed.

1. TMP4100, TMP4150, TMP4155: The incorrect pin type may be entered,

causing a slip. Sharper pins require slower marking speeds, and with

softer material, may hang up in the product being marked. Verify that the

correct operating parameters have been entered. On new installations, try

a slower marking speed.

2. A slip may have occurred while marking due to an interference. The

material being marked may have raised portions which are being struck

by either the impact pin or the cartridge. A “dry run” with the pin retracted

may verify the possible interference.

3. Excessive vibration of the marker in the plane of the marking surface,

normal to the indentation forces, may have caused a slip Due to the

inherent nature of step motor driven systems, there is the possibility of

exceeding the holding force of the motors with impulse forces caused by

vibration. Ensure the mounting of the marker will not promote vibration in

the same plane as the cartridge base/frame traversing components.

4. If the cartridge base/frame mechanism does not fully travel to the Home

position, it may reach the end of travel before the marking is complete

Verify that the full range of travel in both X and Y directions is achievable

by jogging the unit to its extreme positions. If full travel is not possible,

check the flag in that direction for proper location. Check for interference.

Verify there is no internal binding of parts or tubing.

5. The impact pin may be momentarily sticking into the target material,

resulting in excessive drag and slip. The deeper that the impact pin

penetrates the target material, the longer it takes to retract from the

material. This is mostly due to the increased energy transfer into the

target.

Marking time is too long

• The marker is supplied with the factory parameters set to provide the

highest degree of quality and best practical speed for all font selections

and resolutions. The parameter values may be changed, giving you the

ability to customize the setting for your particular application.

• In most cases, marking times will be reduced if you increase the marking

speed. Using the marking system software, display the Marker Properties

and adjust the marking speed parameter, as required, to increase the

speed settings.

• Marking times may also be reduced by decreasing the pixel density (using

Continuous mode), changing the print mode (from Continuous mode to

non-continuous, dot matrix mode), or changing the character font and/or

character size.

• Change the settings as required to better meet your needs, but ensure the

quality of the resulting mark is acceptable.

Loading...

Loading...