Manual 0-2683 9 Introduction

2.3 Service Responsibilities

The Service Technician should be familiar with the equip-

ment and its capabilities and should be prepared to rec-

ommend arrangements of components which will provide

the most efficient layout, utilizing the equipment to its best

possible advantage.

Maintenance work should be accomplished in a timely

manner. If problems are encountered, or the equipment

does not function as specified, contact Technical Services

Department in West Lebanon for assistance.

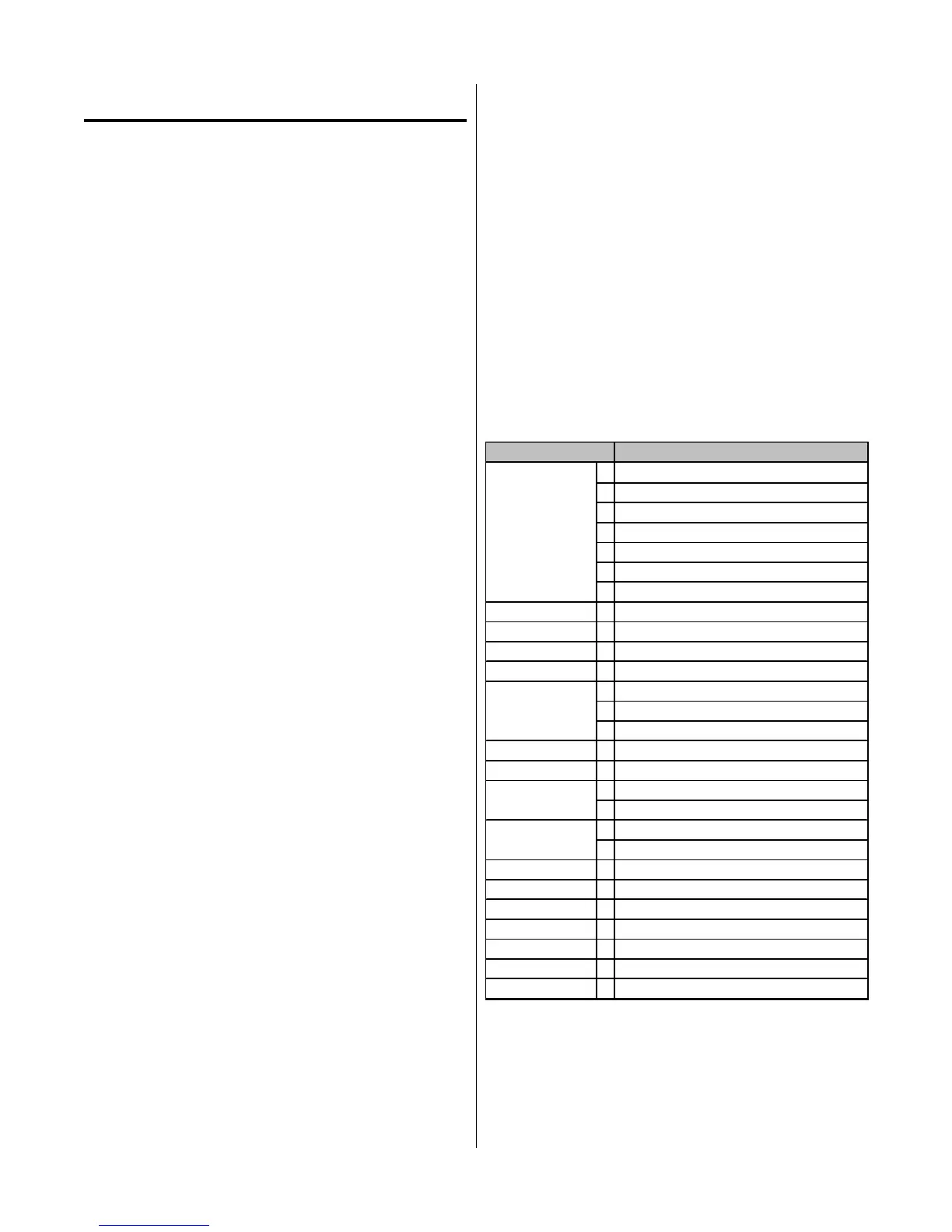

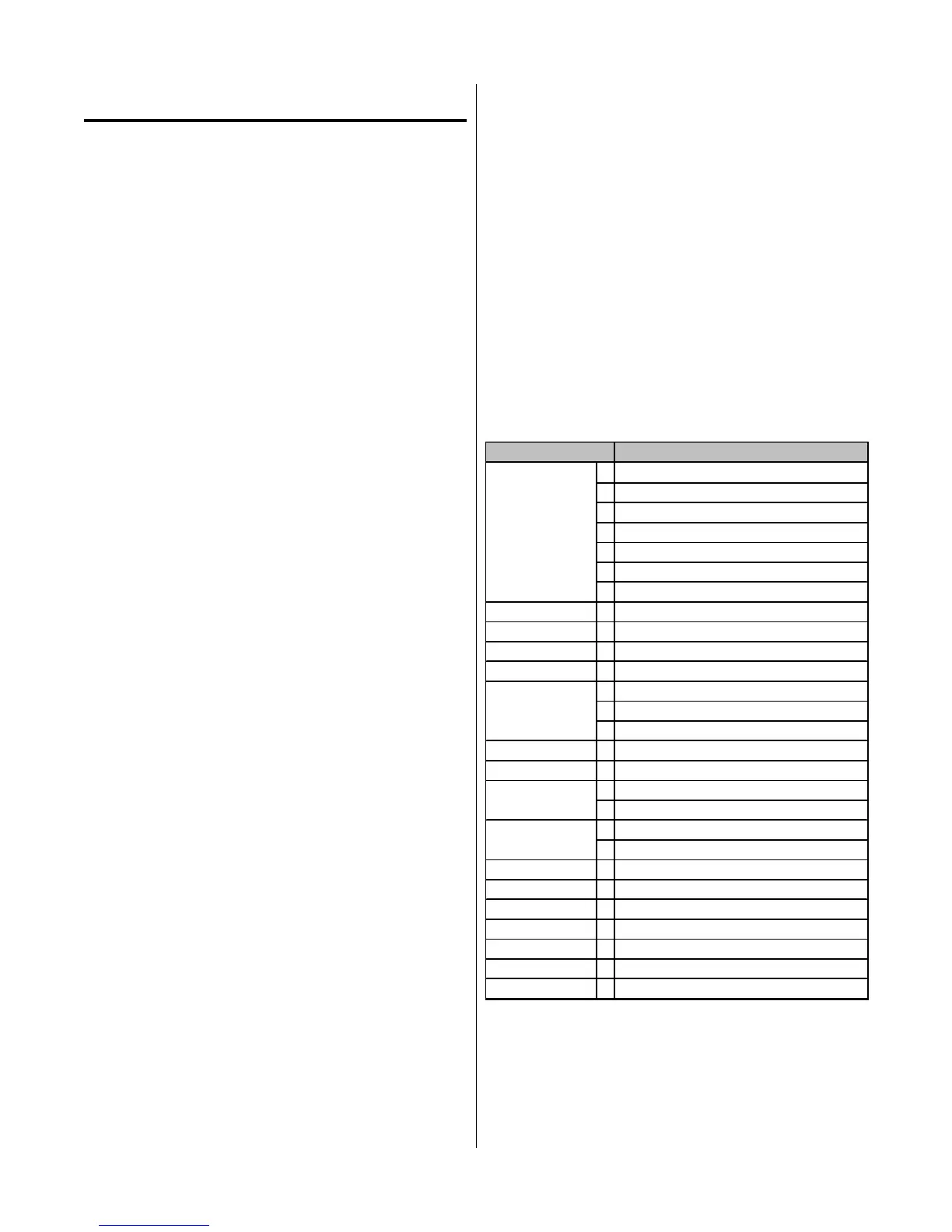

2.4 Technical Specifications

A. System Specifications

System Specifications

Input Power

100 VAC 50Hz, 110 VAC 60Hz, Single Phase

100/110 VAC, 50/60Hz, Single Phase

120VAC ±10%, 50Hz, Single Phase

120VAC ±10%, 60Hz, Single Phase

220VAC ±10%,50Hz, Single Phase

208/230VAC ±10%, 60Hz, Single Phase

Output Power See subsection 2.3B

Duty Cycle See subsection 2.3B

Maximum OCV 280 VDC

Pilot Circuitry Capacitive Discharge (CD), Constant DC

Weight with Leads 55 lbs (24.9 kg)

Power Supply L 16 in. (406 mm)

Dimensions W 9 in. (229 mm)

H 10 in. (254 mm)

Work Cable 15 ft. (4.6 m)

Input Power Cable 6.6 ft. (2 m) minimum

PCH-10 70°

PCH-10 180°

L See subsection 2.4

W See subsection 2.4

Cutting Rating 12 Amps Max. Straight Polarity

Cut Capacity Most metals up to 1/8 in. (3.2 mm) max.

Severance Most metals up to 3/16 in. (4.8 mm)

Pierce Rating 1/16 in. (1.6 mm)

Transfer Distance Approx. 1/8 in. (3.2 mm)

Gas Requirements Compressed Air (Built-in)

Leads Length 20 ft. (6.1 m)

Torch Style

Torch Dimensions

2.0 INTRODUCTION

2.1 Scope Of Manual

This manual provides service instructions for the Ther-

mal Dynamics® DRAG-GUN Plasma Cutter.

Information in this edition is particularly applicable to

the Troubleshooting and Repair of the equipment, and is

intended for use by properly trained Service Technicians

familiar with this equipment.

Read this manual and the DRAG-GUN Operating Manual,

0-2682, thoroughly. A complete understanding of the ca-

pabilities and functions of the equipment will assure ob-

taining the performance for which it was designed.

2.2 General Service Philosophy

Several key points are essential to properly support the

application and operation of this equipment.

A. Application

The equipment should satisfy the customer’s requirements

as supplied and as described in Section 3 of this manual.

Be sure to confirm that the equipment is capable of the

application desired.

B. Modifications

No physical or electrical modifications other than selec-

tion of standard options and accessories are to be made to

this equipment.

C. Customer/Operator Responsibilities

It is the customer/operator's responsibility to maintain

the equipment and peripheral accessories provided by

Thermal Dynamics in good operating order in accordance

with the procedures outlined in the Operating Manual,

and to protect the equipment from accidental or malicious

damage.

D. Repair Restrictions

The electronics consists of a Printed Circuit Board Assem-

bly which must be carefully handled, and must be replaced

as a unit. No replacement of printed circuit solder-mounted

components is allowed except as noted in this manual. If

PC Board is to be returned, the replaced Printed Circuit

Board Assembly must be properly packaged in protective

material and returned intact per normal procedures.

Loading...

Loading...