Manual 0-2683 15 TROUBLE-SHOOTING

3.6 Torch & Leads Troubleshooting

WARNINGS

Disconnect primary power to the system before dis-

assembling the torch, leads, or power supply.

DO NOT touch any internal torch parts while the

AC indicator light on the front panel of the power

supply is on.

Torch parts may get quite hot during normal opera-

tion. Always wear light cutting gloves when chang-

ing torch parts just after operating the Drag-Gun

system.

A. Checking the Center Insulator

The Center Insulator separates the negative and positive

charged sections of the torch. If the center insulator does

not provide adequate resistance, current which is intended

for the pilot arc may be dissipated into the torch head,

resulting in torch failure.

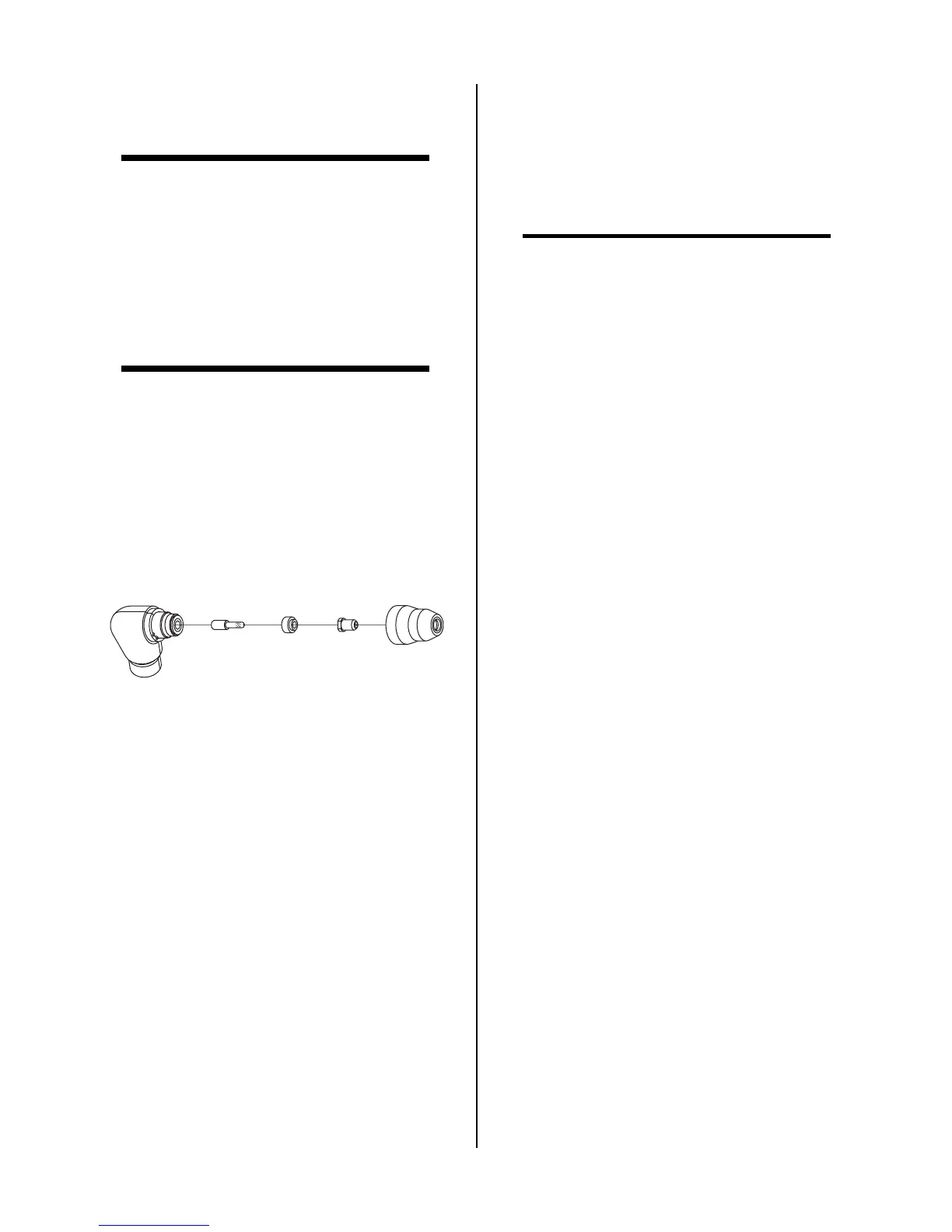

1. Remove the shield cup, tip, gas distributor, and electrode

from the torch.

Torch Head Assembly

Electrode

Tip

Standard

Shield Cup

Gas

Distributor

PCH-10

A-02007

Figure 3-1 PCH-10 Torch Head Parts Removal

2. Disconnect the torch lead from the power supply to

isolate the torch from power supply circuits. Refer to

Appendix I for Leads connections.

3. Using an ohmmeter (set to 10K or higher), check for

continuity between the electrode seat (negative) and the

brass threads of the torch assembly. Infinite resistance

(no continuity) should be found. If there is continuity

between the two, remove the torch head from the lead

and check the torch head separately.

B. Checking Torch Lead

If the torch head assembly is okay, check the torch lead by

measuring the resistance between the positive pilot lead

connector and the negative lead fitting. If continuity is

found, the insulation between the torch leads is breaking

down and the torch and leads assembly should be replaced.

NOTE

The lead cannot be replaced without replacing the

torch assembly as well.

If no continuity is found, check the resistance between the

negative plasma lead fitting and the electrode seat in torch

head. If no continuity is found, replace the torch and leads

assembly.

C. Checking Pilot and Switch Control Wires

Check the pilot and switch control wires for continuity

from one end of the torch lead to the other. If no continuity

exists, replace torch and lead assembly.

D. Reassembling Torch and Leads

Replace parts as required, then recheck the torch head,

and lead connections to confirm proper measurements. If

each component is okay, reassemble torch and leads.

Loading...

Loading...