Manual 0-2683 19 REPLACEMENT PROCEDURES

4.4 Torch Switch Only

Replacement

NOTE

This procedure requires the following tools (or

equivalent): screwdriver, soldering iron, Flux.

WARNING

Disconnect primary power to the system before dis-

assembling the torch, leads, or power supply.

1. Remove consumable parts from front end of torch.

2. Remove the six screws from the torch handle as-

sembly and remove torch and leads assembly.

3. Using soldering iron, carefully remove solder

where orange wire connects to switch terminal.

NOTE

Be careful not to overheat the torch switch while

removing soldering from terminals.

4. Apply Flux to orange wire and to switch post. In-

sert orange wire in switch post hole and solder,

keeping solder at a minimum required for good

joint.

5. Repeat steps 3 and 4, this time for the white wire.

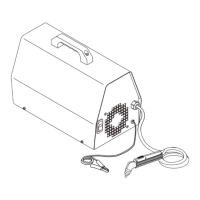

Torch Switch

PIP Pin

PIP Pin

Shield Cup

To Control

Cable Wiring

Butt Splice

A-00784

Figure 4-3 Torch Switch Schematic

6. Place the torch head in the torch handle bottom.

Carefully return the torch switch and button w/

springs to their proper position. Replace cover on

the handle assembly, and screw together with six

screws.

NOTE

Make sure torch switch wires are seated in their

guides so that the wires are not pinched when the

handle is secured.

7. Install consumables parts in front end of torch.

4.5 Air Compressor Replacement

NOTES

Refer to subsection 4.1, General Information, for

information about wire harnesses.

Refer to Appendix II for parts location and orienta-

tion.

1. Remove cover/handle from unit per subsection 4.2.

2. Locate the nylon nut on the 90° nylon fitting on

side of Air Compressor. Loose the nylon nut and

slide the brass torch lead fitting/faston connector

out.

3. Complete one of the following, as it pertains to

your unit:

• Rev C units or earlier - Disconnect black wire

from Compressor to faston splice & wire #21.

Disconnect red wire from Compressor to up-

per diode piggy back terminal.

• Rev D units or later - Disconnect black wire

from Compressor to faston splice & wire #29.

Disconnect red wire from Compressor to up-

per diode piggy back terminal.

4. Slide Compressor out of bracket.

5. Note position and angle of 90° nylon nut connected

to the Air Compressor Remove fitting.

6. Clean old teflon thread sealant from nylon fitting,

apply new thread sealant and install nylon fitting

on replacement Air Compressor. Make sure fitting

is in proper position.

7. Remove “feet” from Compressor and install on re-

placement Compressor.

8. Insert replacement Air Compressor into bracket,

insuring “feet” have dropped into slots in bracket.

9. Apply a small amount of O-Ring lubricant to brass

torch fitting and insert into 90° nylon fitting.

Tighten nylon nut.

NOTE

Be careful not to remove the nylon nut completely

as there are small parts inside that could fall out.

10. Connect the following as it pertains to your unit:

• Connect black wire from Compressor to faston

splice & wire #21. Connect red wire from Com-

pressor to upper diode piggyback terminal.

• Connect black wire from Compressor to faston

splice & wire #29. Connect red wire from Com-

pressor to upper diode piggyback terminal.

Loading...

Loading...