1-12

C3983

C3984

GEAR PUMP 1.2

Assembly

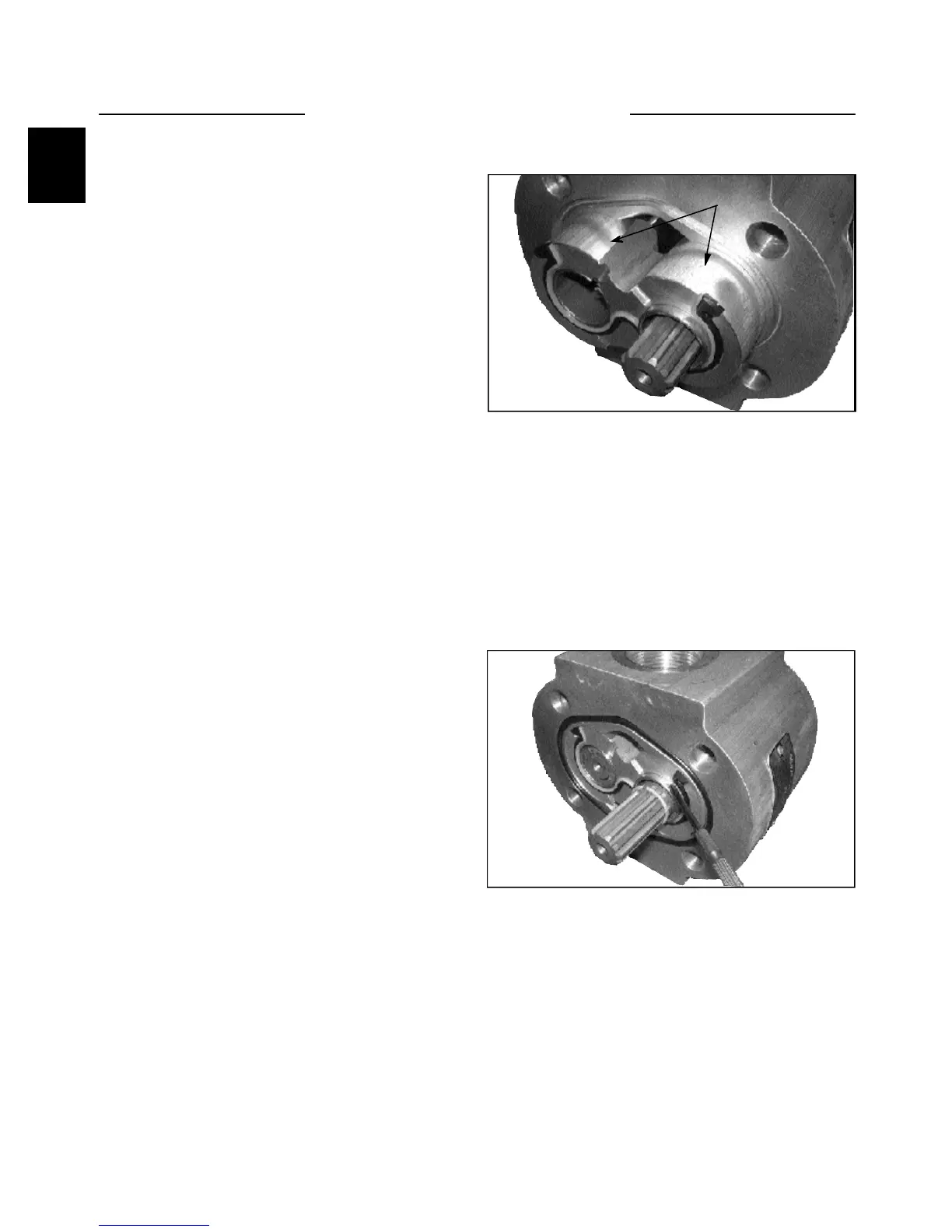

6. Prepare the bearing blocks by cleaning both

blocks (fig. C3983). Inspect the flat surfaces of the

bearing blocks for burrs or scratches on the edges. If

necessary, remove burrs with very fine emery paper.

Then rewash the bearings. Inspect the DU bushings

for wear. There should be no bronze showing. Using

clean hydraulic oil, lubricate the internal and external

surfaces of your blocks.

7. Assemble the bearing blocks and gears.

Lubricate the journals and gear faces. Assemble the

bearing blocks and gears in the same orientation that

it was disassembled. Align all marks made during

disassembly. Ensure the front and rear block occupy

the same location with respect tot he housing as they

did before disassembly. Misalignment of the gear

teeth may increase operating noise.

8. Install the gear and block assembly into the body

of the cavity. Align the assembly marks to ensure that

the gear block assembly is installed with the same

orientation as before assembly.

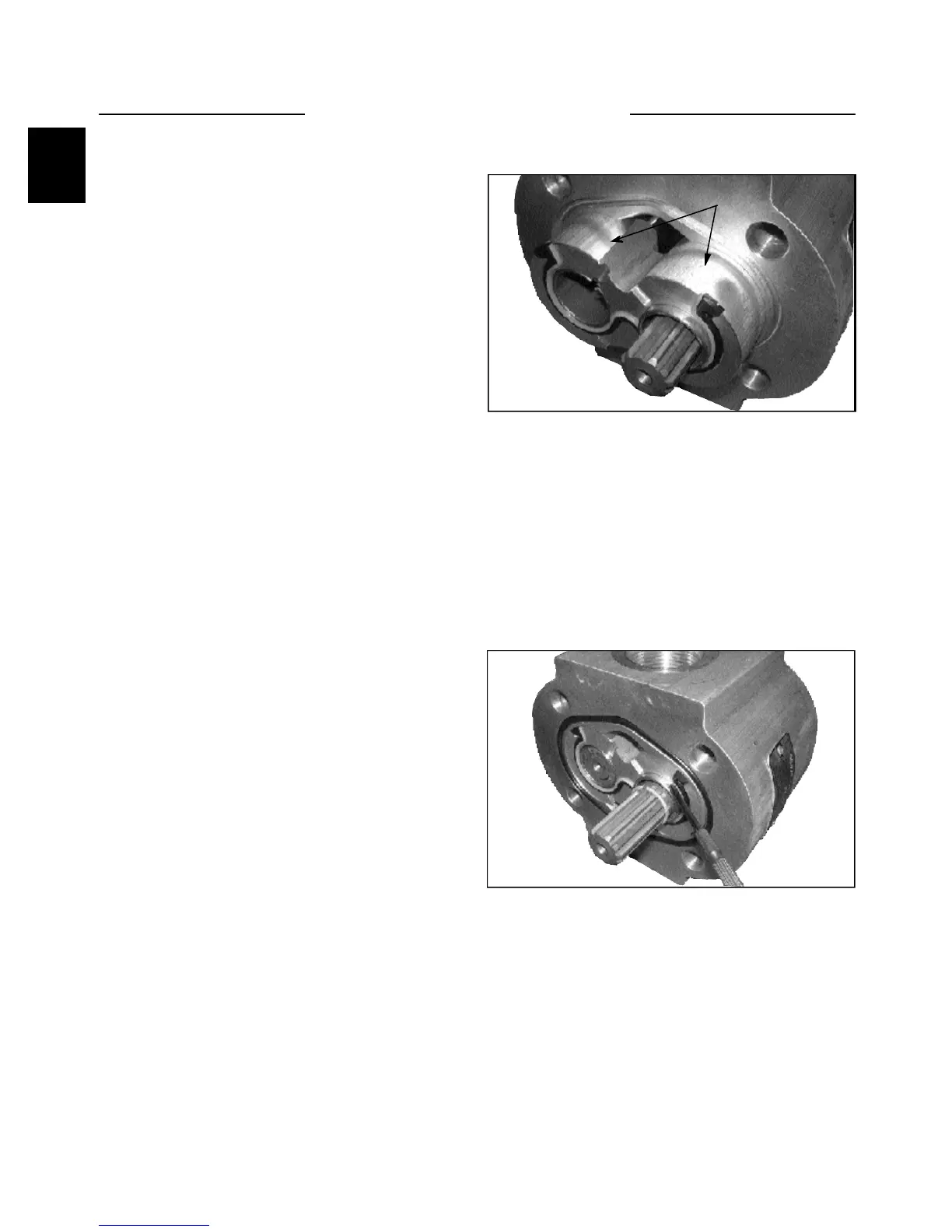

9. Once the gears and the bearing blocks are

installed into the housing, clean the mating surfaces.

Remove any excess lubrication and grease from the

mating surfaces of the pump body. Ensure that these

surfaces are dry and free of contamination before

moving on to the next step. Install the o-rings and

back-up rings on both the bearing blocks and the

housing (fig. C3984).

Blocks

Loading...

Loading...