1-11

Assembly

GEAR PUMP 1.2

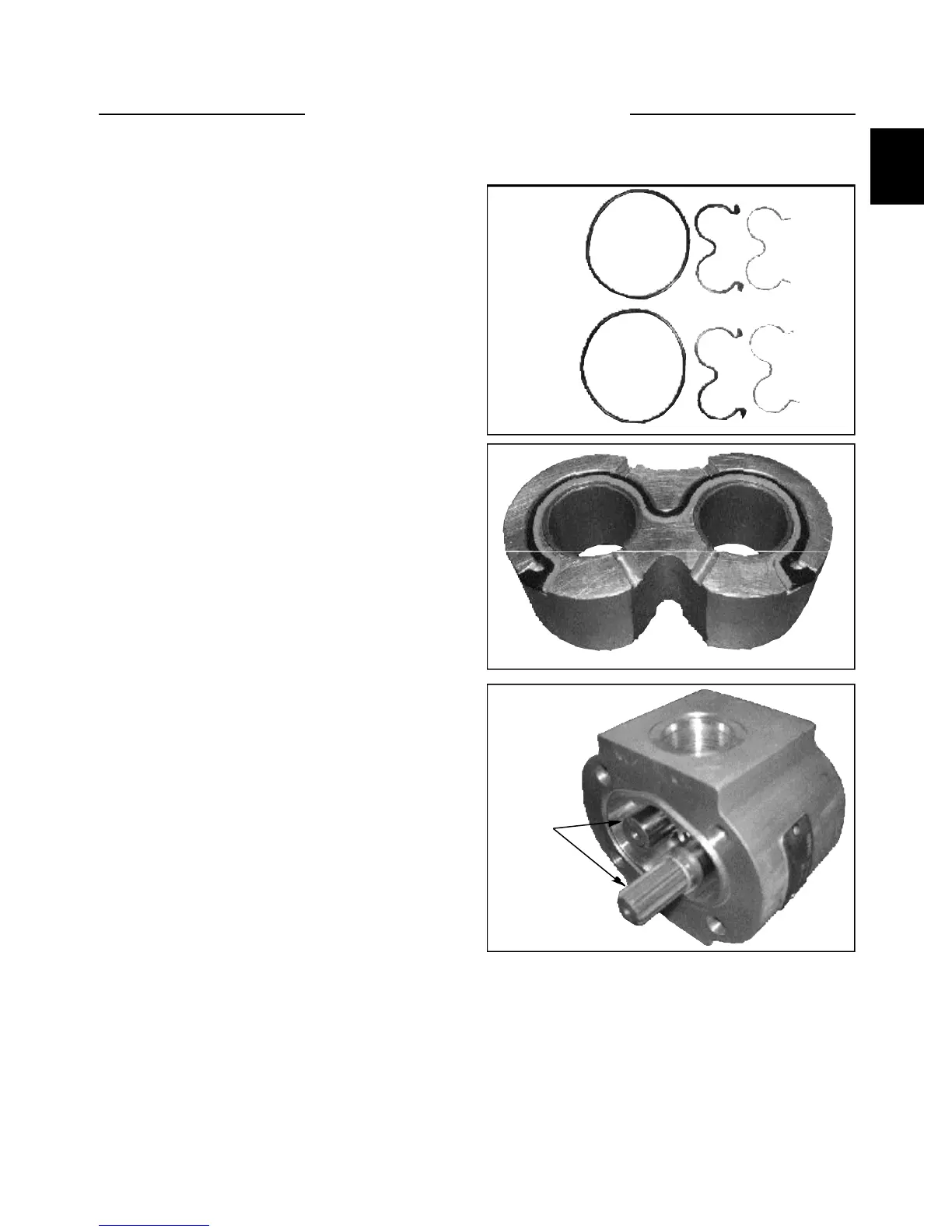

1. Have the entire seal kit available and layed out

neatly on the table (fig. C3980). Compare the old

seal kit to the new one to ensure you have the correct

one. Lightly coat all seals with seal grease. The

grease is needed to adhere the sealsin their grooves.

DO NOT INSTALL DRY SEALS!

2. Install the shaft seal into the front flange (if

applicable). Prepare the flange and shaft seal by

lightly lubricating with grease. Seat the seal in the

flange by hand. Then, using a shaft seal installation

tool press the seal until the tool stops on the flange.

This will insure the seal is inserted to the proper

depth.

3. Install the snap ring using internal snap ring

pliers (fig. 3981). Ensure the snap ring fits securely

in its groove. This is necessary to retain the shaft

seal.

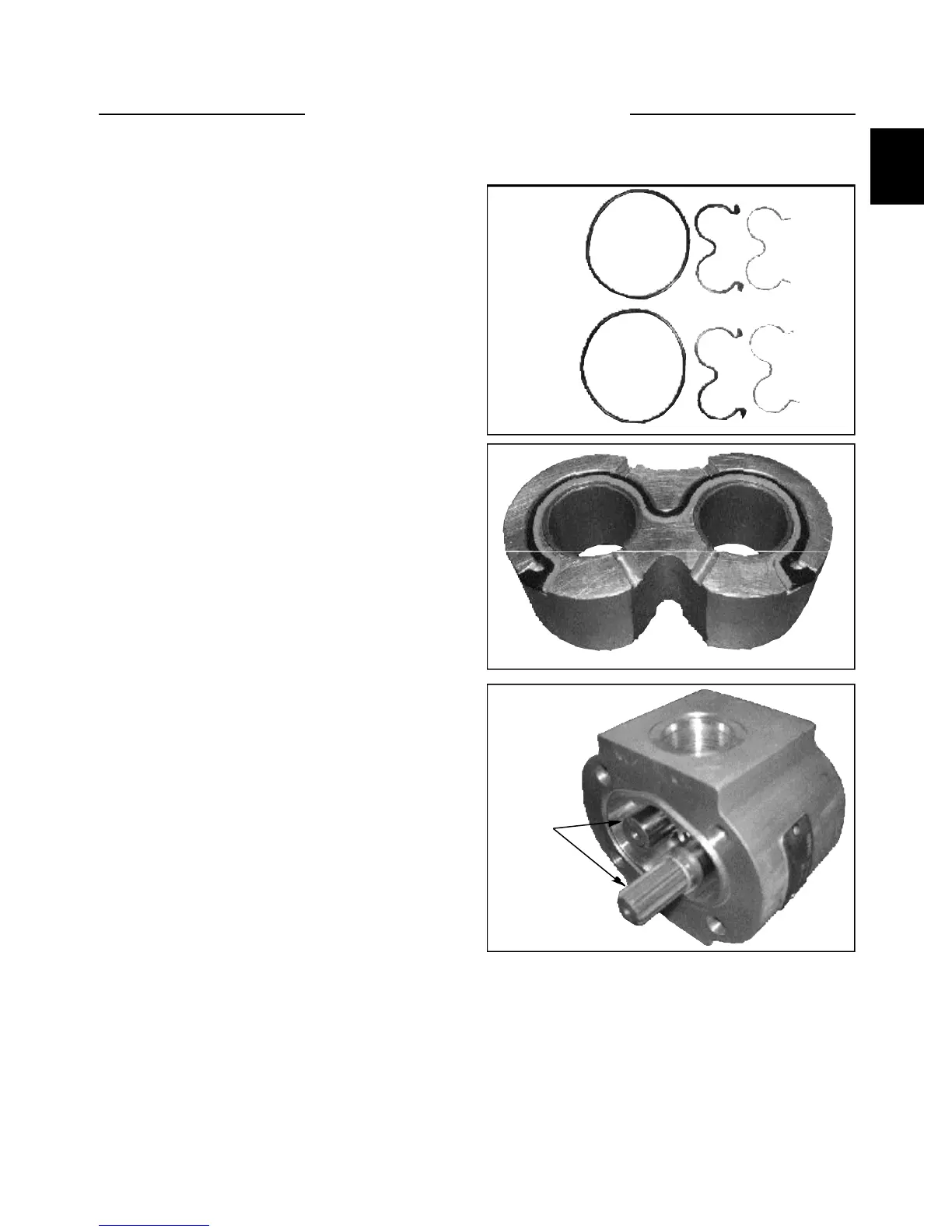

4. Prepare the body by cleaning it. Inspect the

internal and mating surfaces. Ensure the surfaces are

free of burrs and scratches. Check both the bearing

block mating surface and the cut-in path.

5. Prepare the gears (fig. C3982). Caution, the gear

surfaces are superfinished. Residue on hands and

fingers may be corrosive to this surface. DO NOT

TOUCH. Carefully clean the two gears. Inspect the

journals and the flat faces on the top and bottom of

the gears. Ensure these surfaces are free from burrs

or scratches. If scratches are found, clean them with a

flat stone and/or very fine emery paper. Rewash the

gears after this operation.

C3980

C3981

C3982

Gears

Loading...

Loading...